RTC clock calibration method and industrial field calibration device

A clock calibration and industrial site technology, applied to clocks, electronic timers, and time indications, etc., can solve complex changes in the on-site working environment, increase calibration costs and complexity, and are not suitable for external standard clocks and on-site instrument calibration Problems such as carrying the device with you

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

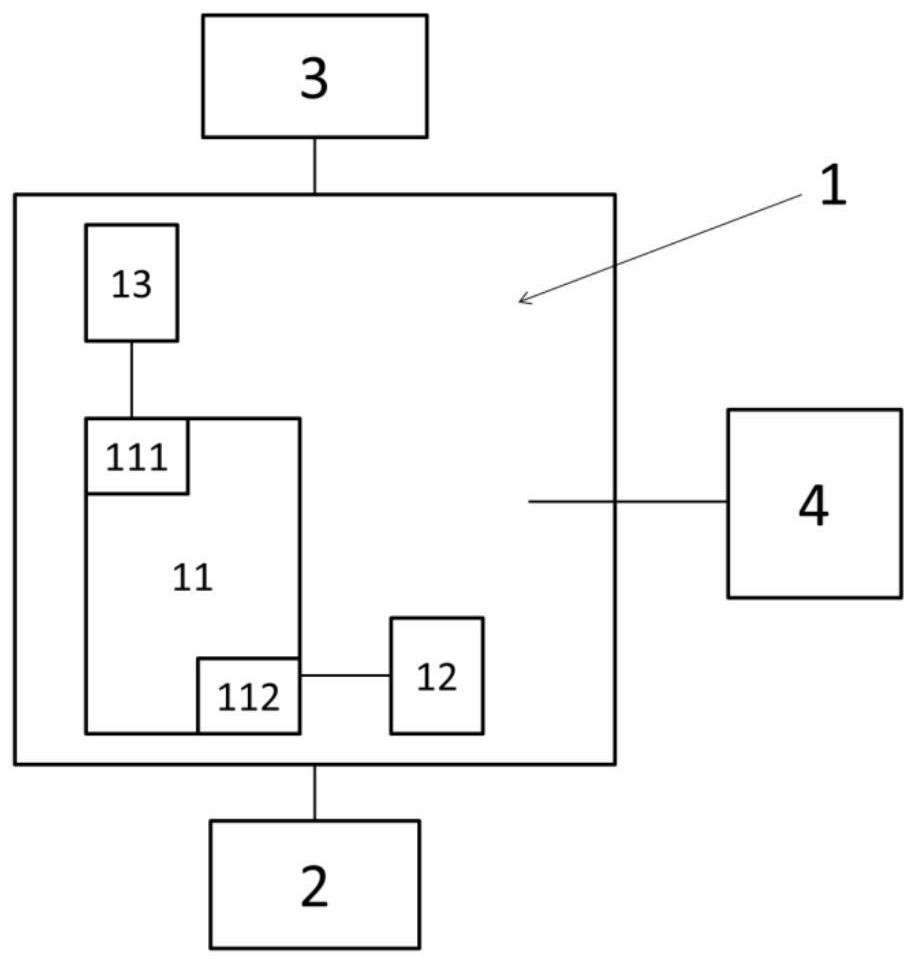

[0055] In this embodiment, a pressure (instrument) calibrating device used for calibrating or calibrating a pressure instrument in an industrial field is taken as an example to illustrate the RTC clock calibration process of the calibrating device in an industrial field. figure 1 The basic composition of a typical pressure calibration device is shown: the pressure calibration device includes an MCU main board 1, a pressure acquisition module 2, an electrical signal measurement module 3 and a battery module 4, and the pressure acquisition module and the electrical signal measurement module 3 are respectively connected to the MCU main board 1 is electrically connected, and the battery module 4 is electrically connected to the MCU main board 1 for supplying power to each module.

[0056] Wherein, MCU motherboard 1 is provided with processing unit (i.e. CPU) 11, high frequency crystal oscillator (hereinafter referred to as HSE) 12 and low frequency crystal oscillator (LSE) 13, is p...

Embodiment 2

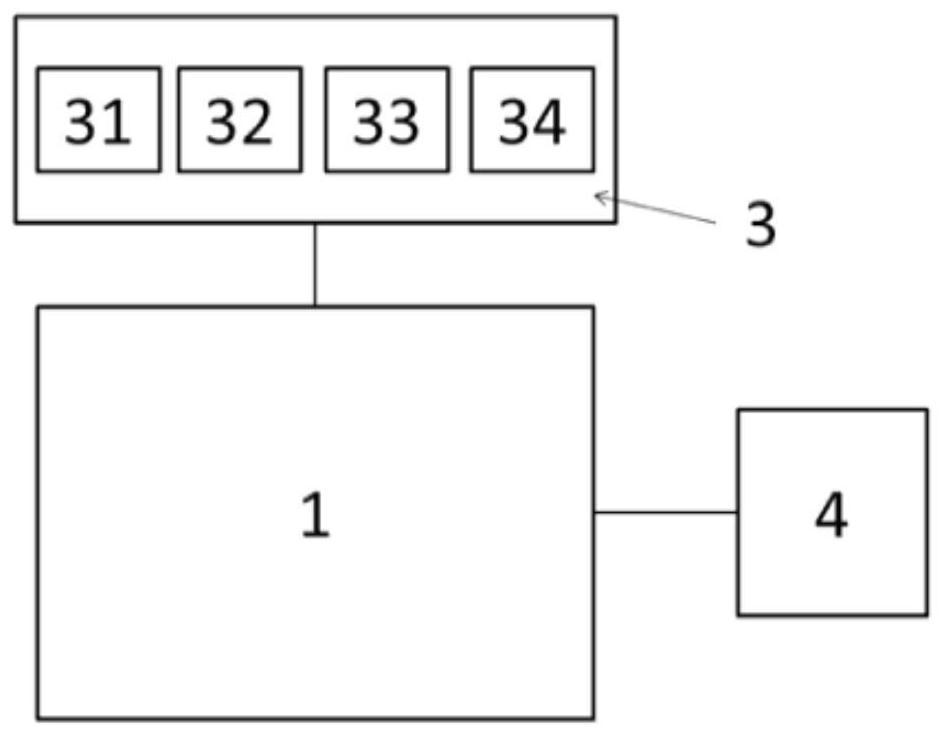

[0074] In this embodiment, a process (instrument) verification device for verifying or calibrating a process instrument in an industrial field is taken as an example to illustrate the RTC clock calibration process of the industrial field verification device. figure 2 The basic composition of a typical process verification device is shown: the process verification device includes an MCU main board 1, an electrical signal measurement module 3 and a battery module 4, further, the electrical signal measurement module 3 includes a current measurement unit 31, a voltage measurement unit 32, The resistance measurement unit 33 and the temperature measurement unit 34, the temperature measurement unit 34 includes a temperature sensor, which can measure the ambient temperature of the electrical signal measurement module 3 as the cold junction temperature when the thermocouple process signal is calibrated.

[0075] The difference from the pressure calibration device in Embodiment 1 is tha...

Embodiment 3

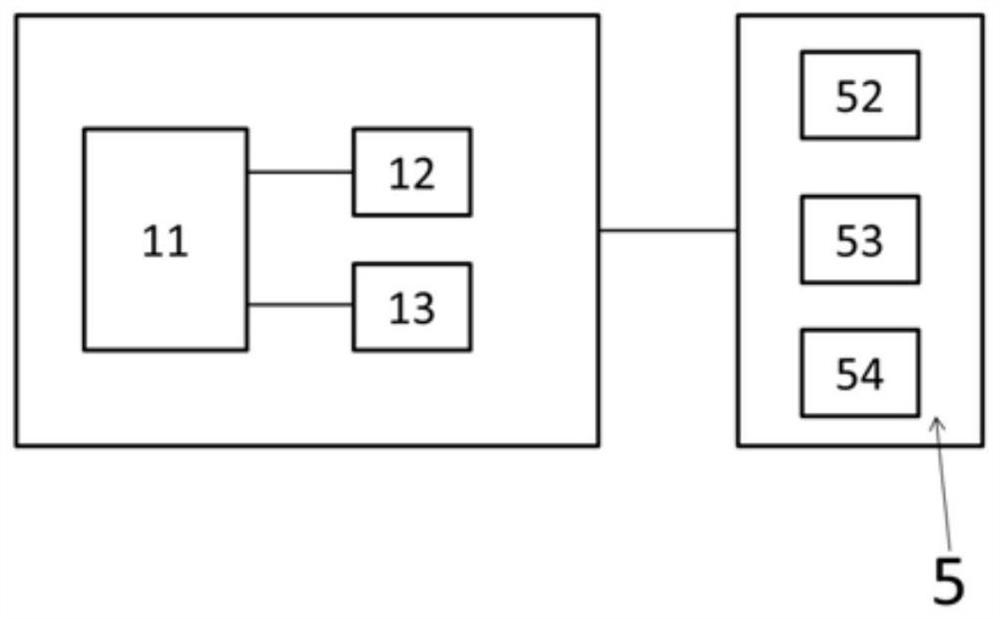

[0085] In this embodiment, a temperature (instrument) verification device used for verifying or calibrating a temperature instrument in an industrial field is taken as an example to illustrate the RTC clock calibration process of the industrial field verification device. image 3 The basic composition of a typical temperature calibration device is shown: in this embodiment, the temperature calibration device includes an MCU main board 1 and a temperature acquisition module 5 electrically connected to the MCU main board 1, wherein:

[0086] MCU motherboard 1 includes a processing unit (CPU) 11 and a clock module formed by high-frequency crystal oscillator (HSE) 12 and low-frequency crystal oscillator (LSE) 13, HSE is used as the system clock signal source of MCU motherboard 1, and also as a high-frequency calibration of LSE Clock signal, preferably, when HSE is used as a high-frequency calibration signal of LSE, frequency multiplication technology is used to increase its frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com