A gas oxygen/gas methane torch igniter

A torch igniter, gas methane technology, which is applied in the directions of combustion ignition, indirect carbon dioxide emission reduction, combustion methods, etc., can solve the problems of inability to meet temperature requirements, difficulty, secondary supplementary combustion failure, etc., and reduce thermal protection requirements. , the effect of reduced difficulty and large working margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below in conjunction with the drawings.

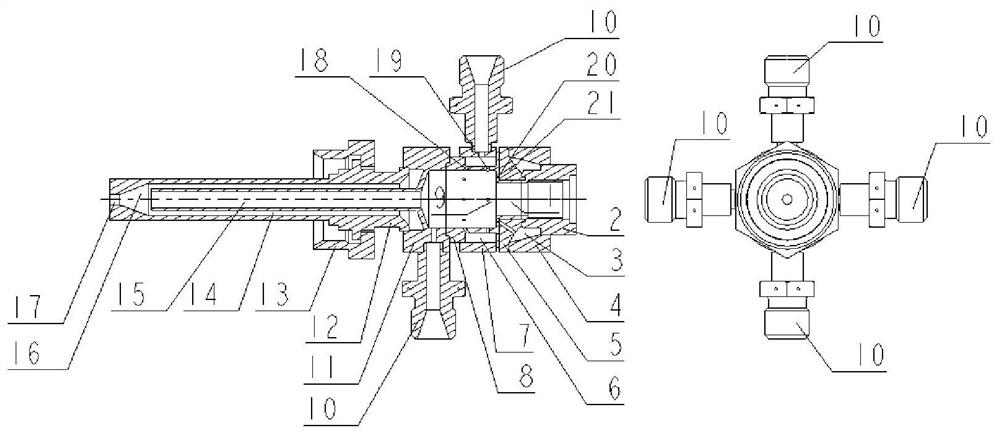

[0028]Such asfigure 1 As shown, a gas-oxygen / gas-methane torch igniter includes a spark plug seat 2, a gas-methane gas collecting chamber outer shell 4, a gas-methane injection hole base 5, a gas-oxygen gas collecting chamber outer shell 7, and an ignition chamber body Shell 8, ignition chamber throat shell 11, gas pipe outer shell 12, jacket nut 13 and welding through 10.

[0029]The gas methane injection hole base 5 is in the shape of a frustum. It extends from one end of the gas methane gas collecting chamber shell 4 into the gas methane gas collecting chamber shell 4, and one end of the gas methane injection hole base 5 is stuck in the gas methane collecting chamber. At the port of the gas chamber casing 4; one end of the spark plug holder 2 extends from the gas methane gas collecting chamber casing 4 into the gas methane gas collecting chamber casing 4 and the gas methane injection hole ba...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap