Gaseous coal friction-adsorption/desorption test device and test method

A test device and test method technology, applied in the field of mining and rock mechanics, can solve the problem that the coupling effect of gas adsorption and desorption characteristics cannot be truly simulated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

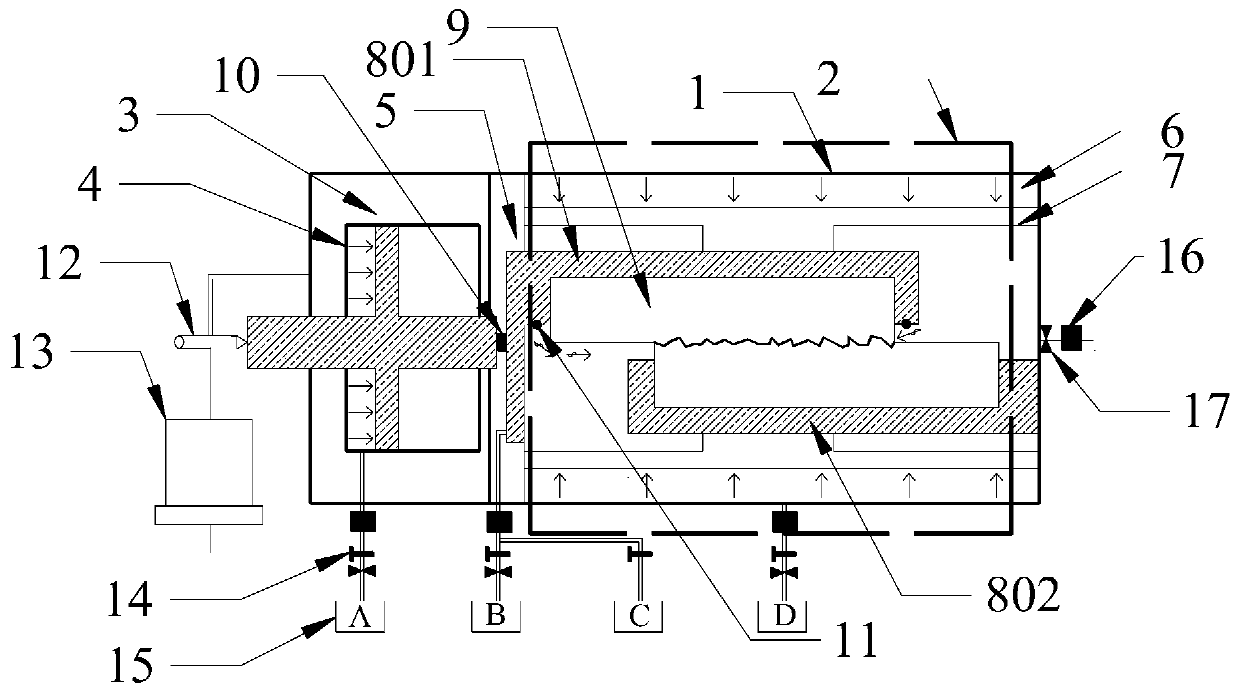

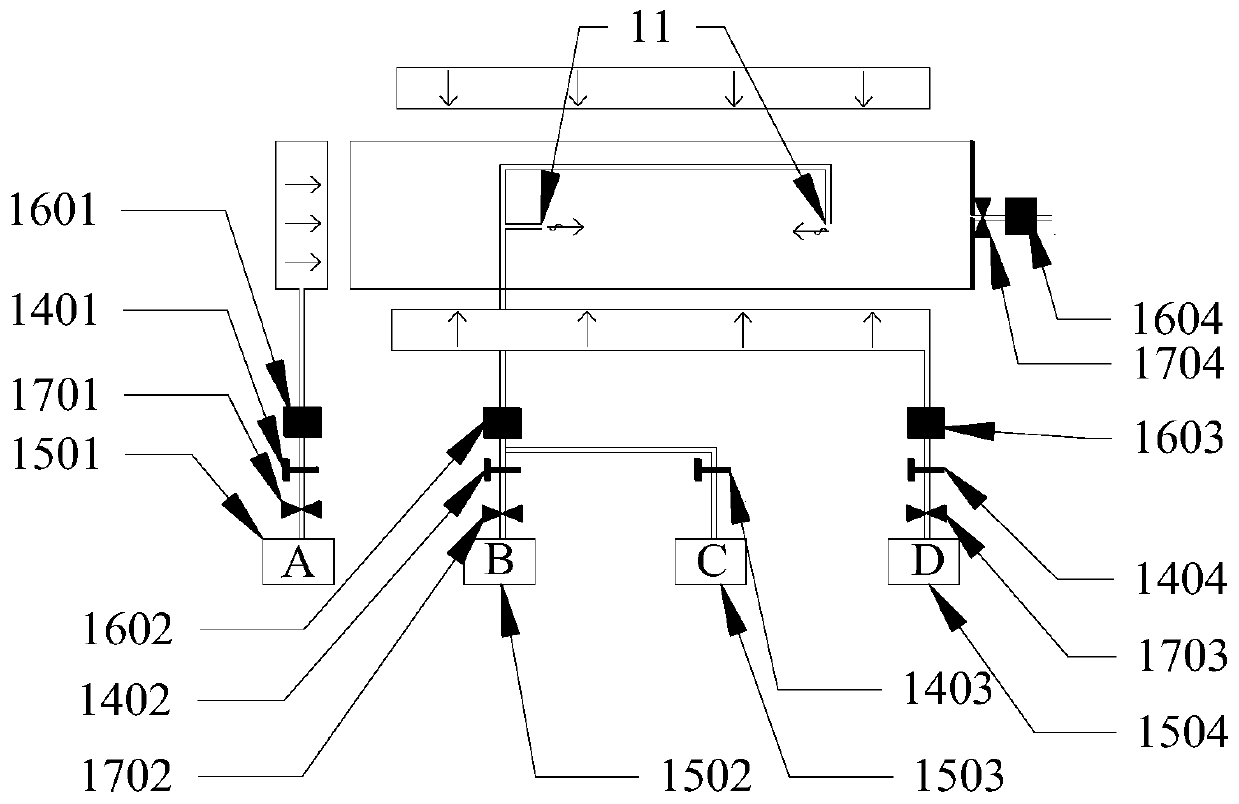

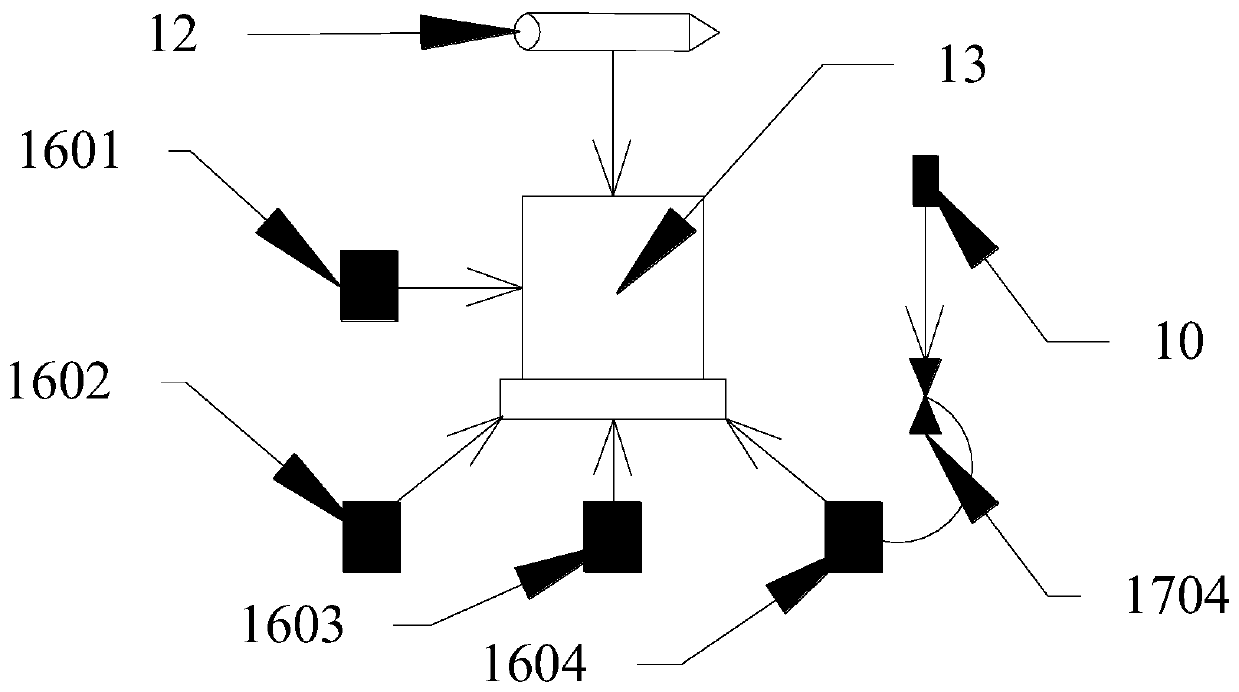

[0030] Such as figure 1 and figure 2 As shown, a gas-containing coal friction-adsorption / desorption test device includes a gas-containing coal friction device system, a gas injection / pressurization pipeline, and a real-time data acquisition and processing system; its main part is a gas-containing coal friction device system 1, The interior includes a first chamber 3 and a second chamber 5. The first chamber 3 is located on the front side of the system 1, and is equipped with a hydraulic cylinder 4 for applying axial pressure. The hydraulic cylinder is externally connected to an axial pressure pipeline hydraulic pump 1501. The chamber 5 is located on the rear side of the system 1, and the outside of the chamber 5 is equipped with a constant temperature box 2. The second chamber 5 is a closed space when the valve is fully closed. Gas coal body 9, wherein the upper clamp 801 is slidable, the lower clamp 802 is fixed, and the upper and lower clamps 8 are sealed and wrapped by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com