Novel vacuum circuit breaker insulating sheath

A technology of vacuum circuit breaker and insulating sheath, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of shortening the service life of vacuum circuit breakers, poor sealing performance of insulating shells, etc., and achieves a simple and practical connection method. Good sealing, reducing the effect of openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

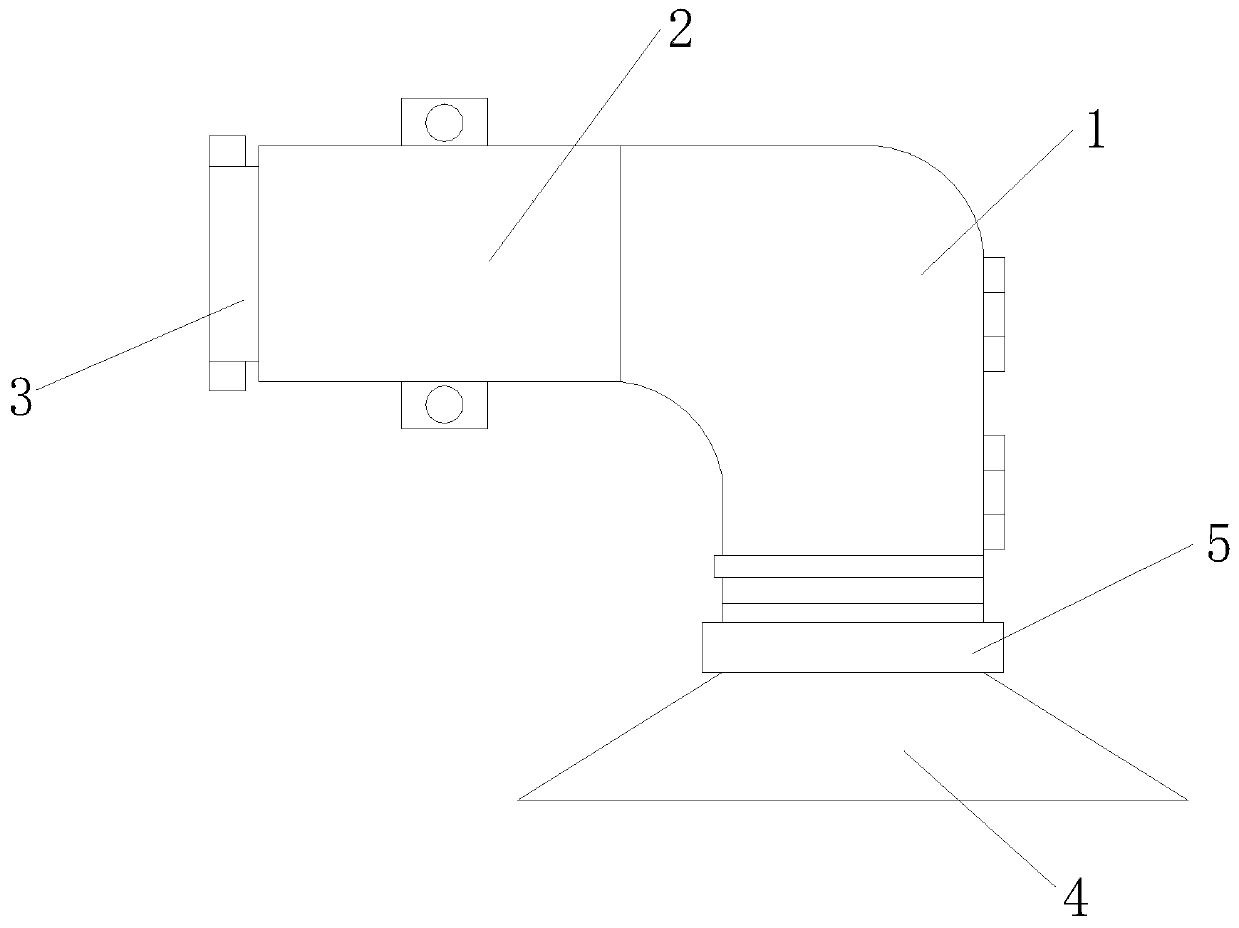

[0028] like Figure 1-5 As shown, the embodiment of the present invention provides a novel vacuum circuit breaker insulating sheath, including a rear insulating sheath 1, a front insulating sheath 2 is fixedly connected to the left side of the rear insulating sheath 1, and a front insulating sheath 2 The wire fixing assembly 3 is arranged on the left side, the bottom of the insulating sheath 1 at the rear end is threadedly connected with an insulating sheath fixing seat 4, and the upper end of the insulating sheath fixing seat 4 is threadedly connected with a protective nut 5, and the wire at the joint of the vacuum circuit breaker is connected to Enter from the bottom of the insulating sheath fixing seat 4, the wire passes through the cavity inside the rear insulating sheath 1 and the front insulating sheath 2, and then comes out from the left end of the front insulating sheath 2, and then passes the wire end through the wire fixing assembly 3, and finally install the insulat...

Embodiment 2

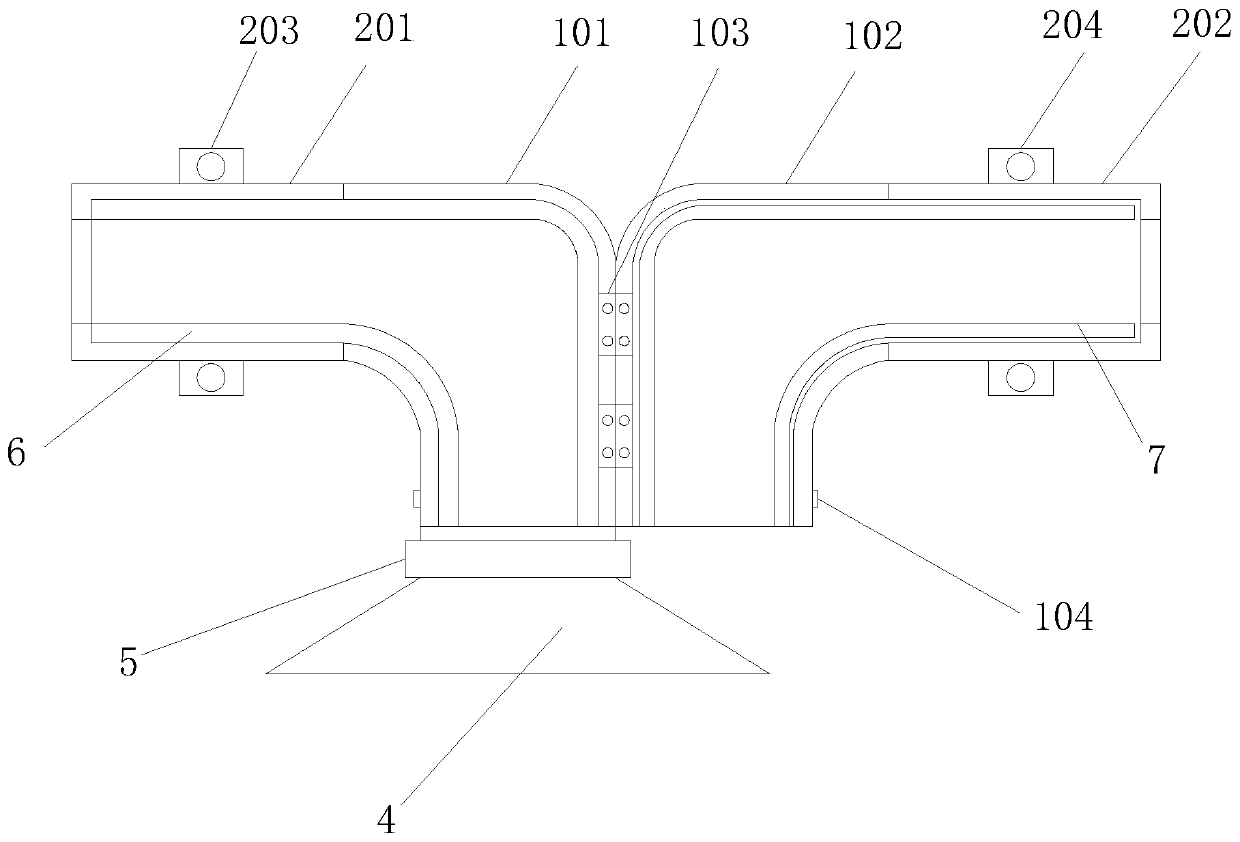

[0030] like figure 1 , 2 As shown, the embodiment of the present invention provides a novel vacuum circuit breaker insulating sheath. The rear end insulating sheath 1 is composed of a first rear end sheath shell 101 and a second rear end sheath shell 102. The first rear end The sheath housing 101 and the second rear sheath housing 102 are movably connected through a connecting hinge 103, the first rear sheath housing 101 is screwed to the top of the insulating sheath fixing seat 4, and the first rear sheath housing The side walls of the body 101 and the second rear sheath housing 102 are fixedly connected to the limit ring 104, and the inside of the first rear sheath housing 101 and the second rear sheath housing 102 form an arc-shaped cavity. Cavity, the front-end insulating sheath 2 is composed of the first front-end sheath shell 201 and the second front-end sheath shell 202, and the inside of the first front-end sheath shell 201 and the second front-end sheath shell 202 fo...

Embodiment 3

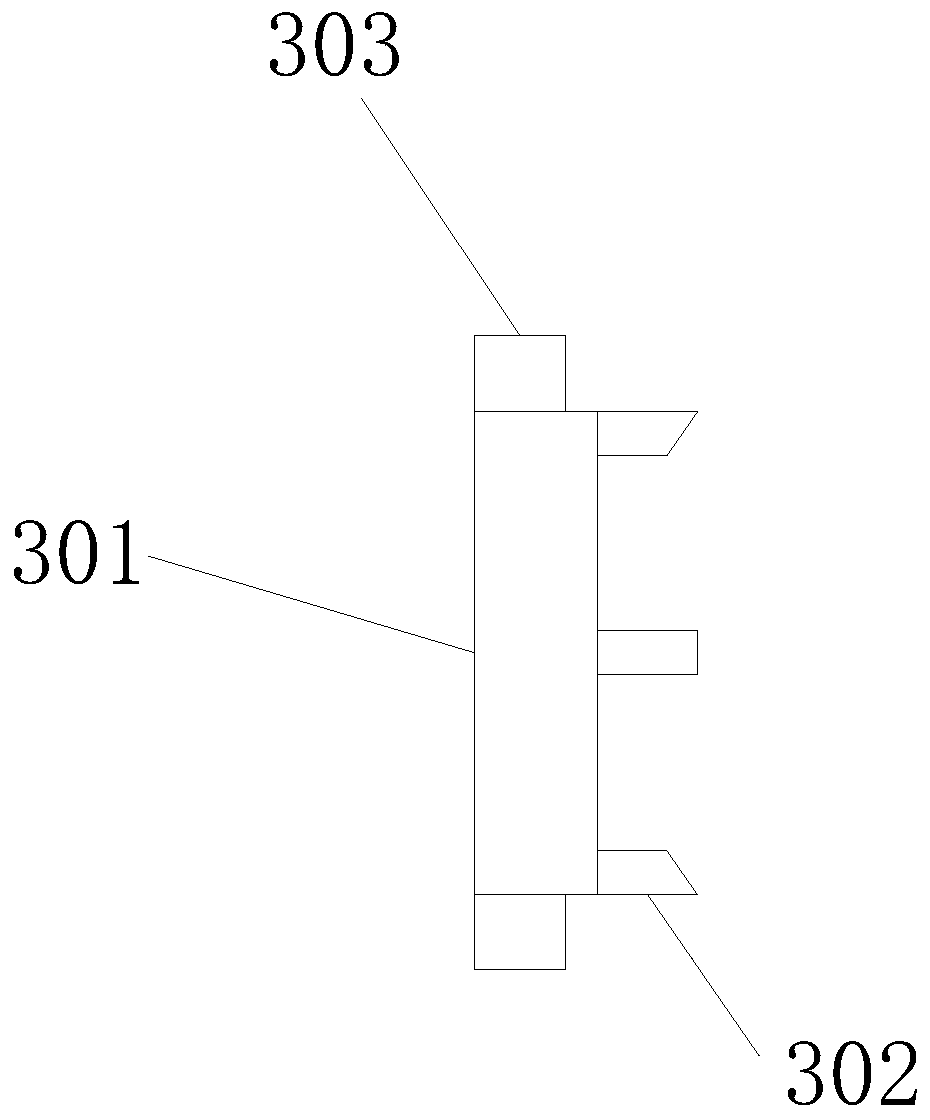

[0032] like figure 1 , 2, 3, and 4, the embodiment of the present invention provides a new type of vacuum circuit breaker insulation sheath, the wire fixing assembly 3 includes a sleeved circular plate 301, and several plug blocks 302 are fixedly connected to the right side of the sleeved circular plate 301 , and the left side wall of the front end insulating sheath 2 is provided with a socket suitable for the plug-in block 302, the upper and lower ends of the socketed circular plate 301 are fixedly installed with a fixed block 303, and the side of the socketed circular plate 301 A round hole is opened on the wall, and a rubber washer 304 is fixedly installed inside the round hole. After the circuit breaker wire comes out from the left end of the front insulating sheath 2, the lead wire is passed through the rubber washer installed on the side wall of the socket circular plate 301. 304, and then insert the socket block 302 at the right end of the socketed circular plate 301 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com