Composite insulator vibration deicing device and deicing method

A technology of composite insulators and power units, used in overhead installation, cable installation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

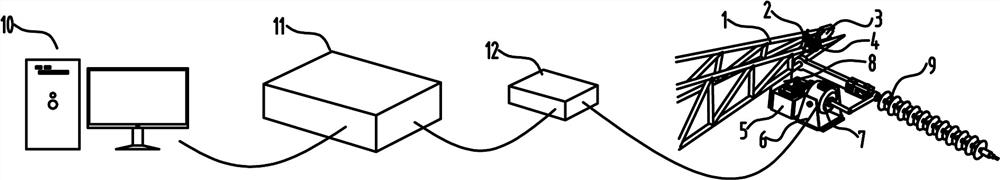

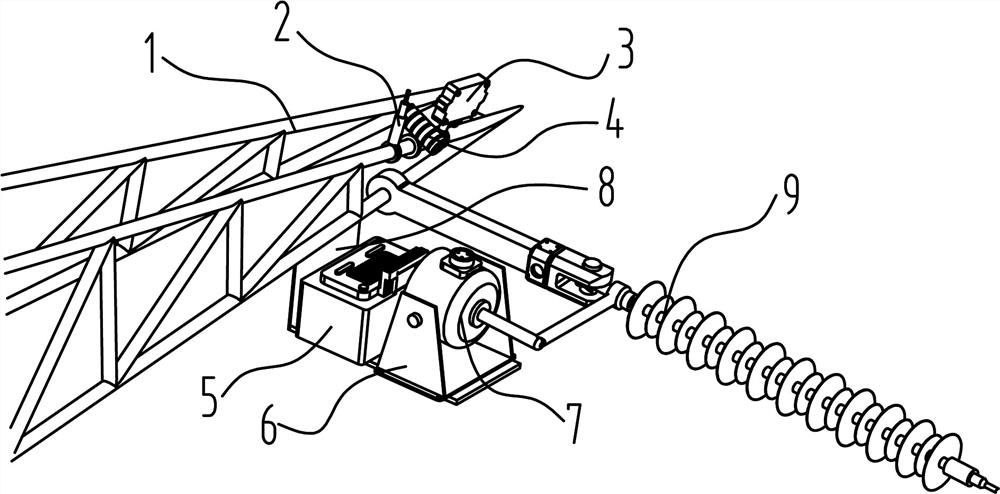

[0033]Such asFigure 1~10As shown, a composite insulator vibration deicing device and a deicing method include a power device fixedly connected to the elevated tower 1, and the power device is mechanically connected to the composite insulator 9; the power device is used to output and drive the composite insulator 9 along the axis Reciprocate in a straight line.

[0034]In a preferred solution, the platform 8 in the power plant is fixedly connected to the elevated tower 1, and the deicing device 7 is provided on the platform 8. With this structure, the device is fixedly connected to the elevated tower 1 to prevent the device from loosening or falling , Easy to use and reliable.

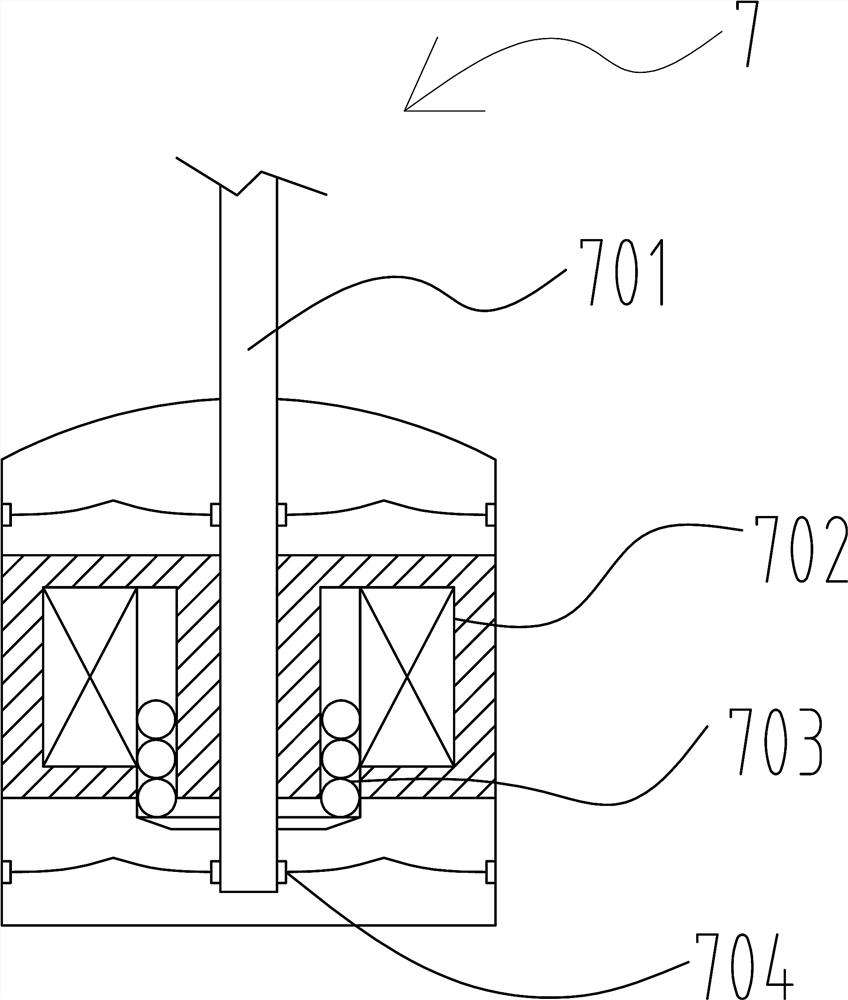

[0035]In a preferred solution, the ejector rod 701 in the deicing device 7 passes through the excitation coil 702 and is connected to the moving coil 703. One end of the ejector rod 701 is provided with a support spring 704, and the other end of the ejector rod 701 is provided with a chuck 705. The head 705 is fixe...

Embodiment 2

[0043]It is further explained in conjunction with Example 1, such asFigure 1~10As shown, when the camera 3 on the elevated tower 1 monitors the on-site ice thickness to meet the requirements; the control host 10 sends a command to the sweep signal generator 11; the sweep signal generator 11 receives the command and sends a specific frequency to the power amplifier 12 ; The frequency is amplified by the power amplifier 12 and then transmitted to the deicing device 7 over a long distance; the deicing device 7 is activated for vibration deicing.

Embodiment 3

[0045]In combination with the above embodiments, it will be further explained, such asFigure 1~10As shown, the test shows that the first 6 modes of the composite insulator 9 are all concentrated at low-order frequencies, and the first-order characteristic frequency is 29.37 Hz. The vibration characteristics of the composite insulator 9 are mainly based on the bending mode. At this time, the vibration has little effect on the bonding stability between the shed material and the core rod; the middle of the shed of the composite insulator 9, that is close to the core rod, has the largest stress. It can reach 0.8Mpa, and when extending from the shaft center to the surroundings, the stress generated gradually decreases. The stress at the edge of the umbrella skirt is about 0.4Mpa. As a result of the test, the deicing device 7 uses the SA-JZ005 type vibration exciter, which can operate normally in the low frequency range and can generate an exciting force of about 15000 N / m2, which can mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com