The pressure sensor automatically adjusts the shaking plate and the grain transfer device

A technology of pressure sensor and shaking plate, which is applied in threshing equipment, agriculture, application, etc., can solve the problems of difficult to ensure the high quality of corn kernels, the unadjustable vibration frequency of the shaking plate, and low operating efficiency. Good selection of operation quality, high degree of automation, and high operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

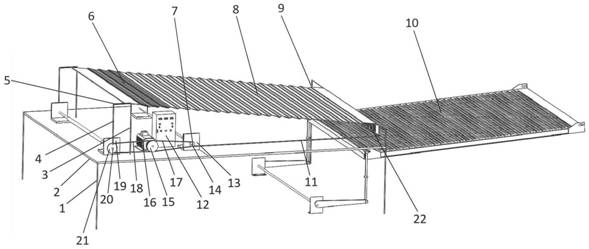

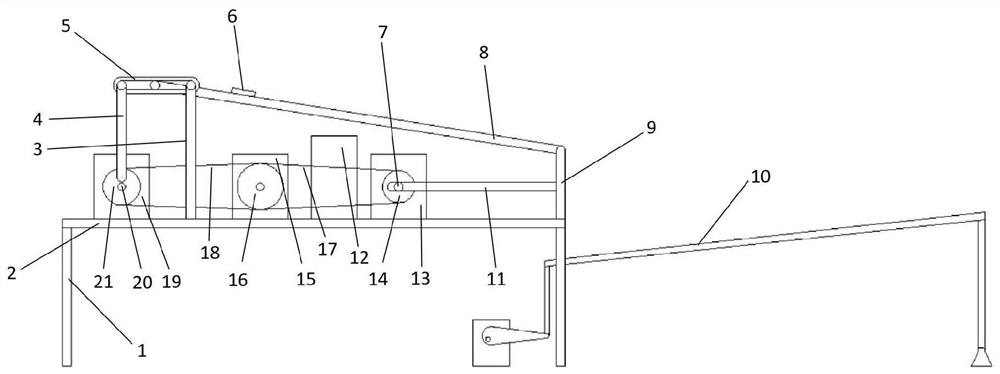

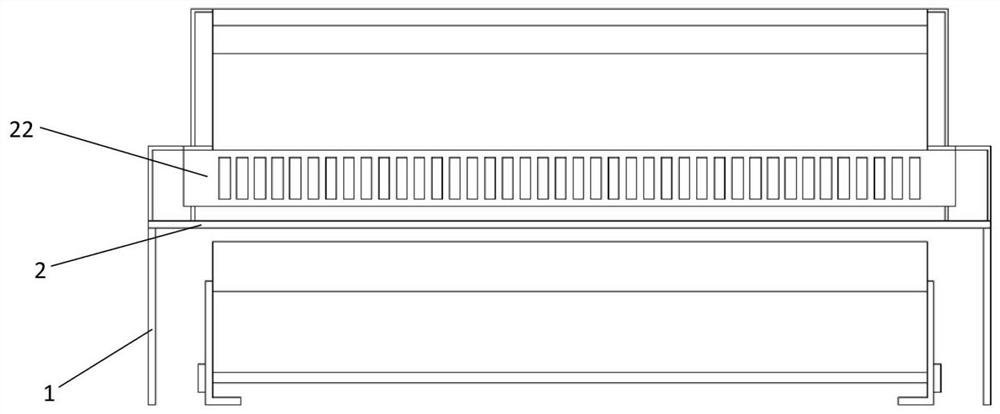

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A pressure sensor automatically adjusts the shaking plate grain dialing device, including a vibrating cleaning screen assembly 10, a device frame 1 is arranged at the front part of the vibrating cleaning screen assembly 10, and a seat is installed on the upper end of the device frame 1 Plate 2, on the left and right sides of the front end of the seat plate 2, support seats A19 are respectively installed symmetrically, and the power transmission shaft A20 is rotatably inserted and supported on the support seat A19, and at the two ends of the power transmission shaft A20 Crank pulleys A21 are respectively fixed on the top; on the left and right sides in the middle of the seat plate 2, the support seats B13 are respectively symmetrically installed at the rear of the support seat A19, and the power transmission shaft B7 is rotatably inserted and supported. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com