Rotary thin-wall tank forming device

A molding device and rotary technology, which can be applied to other household appliances, household appliances, applications, etc., can solve the problems of low work efficiency and cumbersomeness, and achieve the effects of improving work efficiency, reducing labor intensity, and ingenious device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

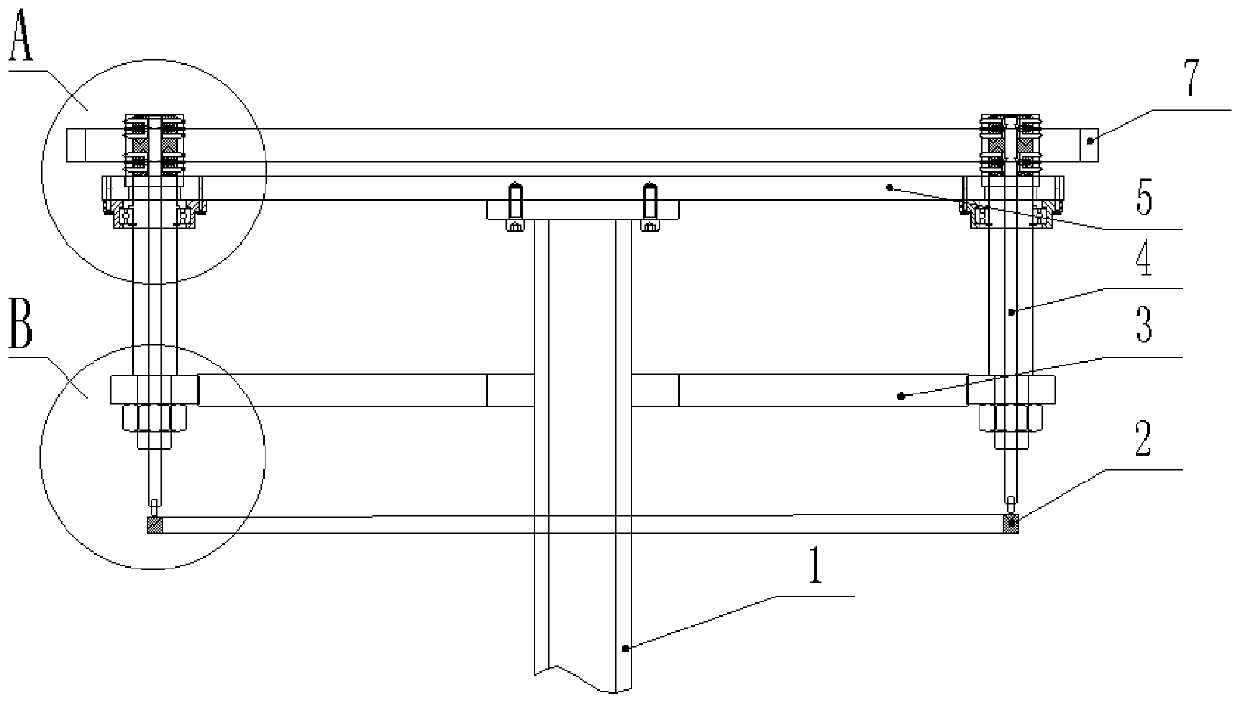

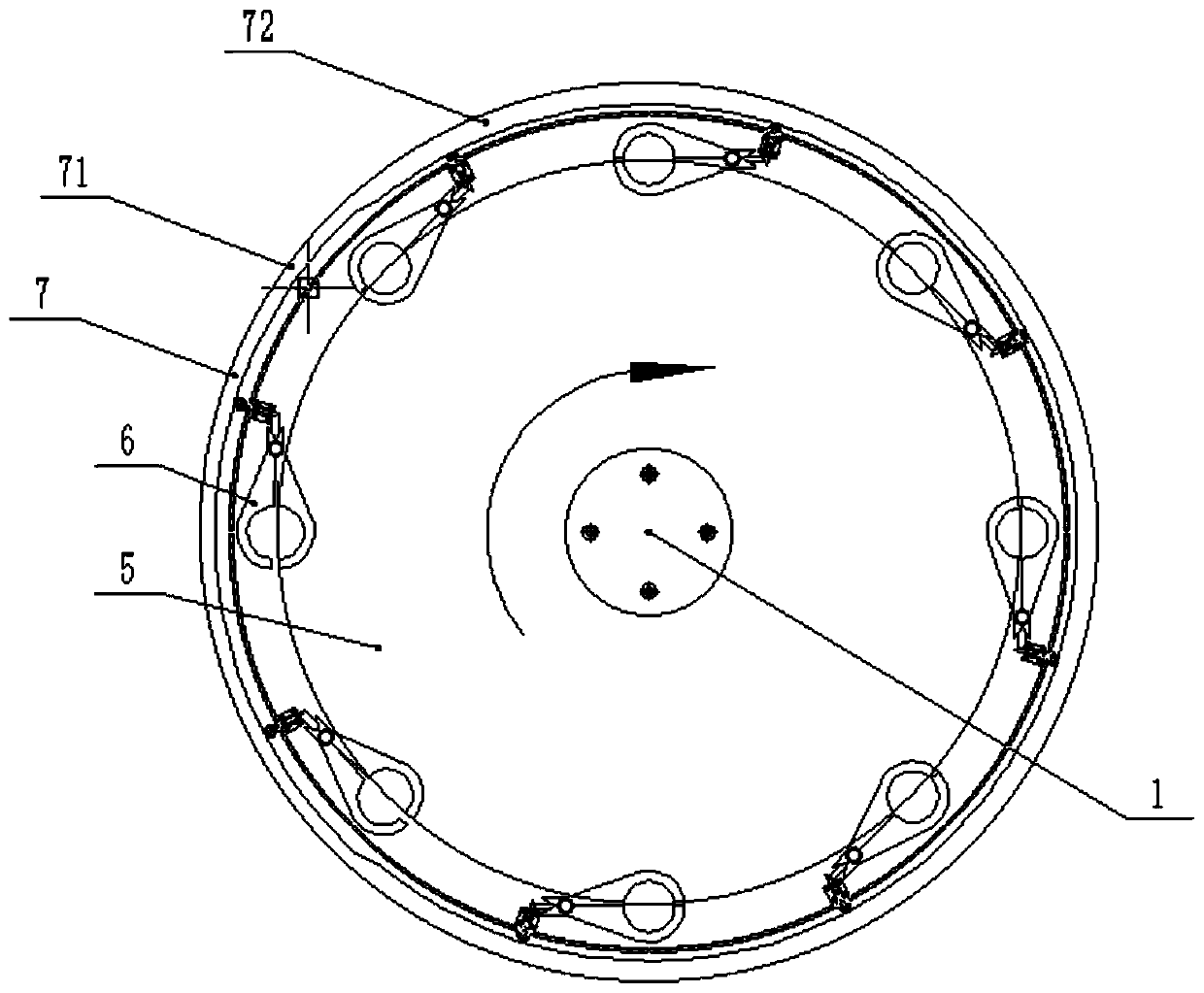

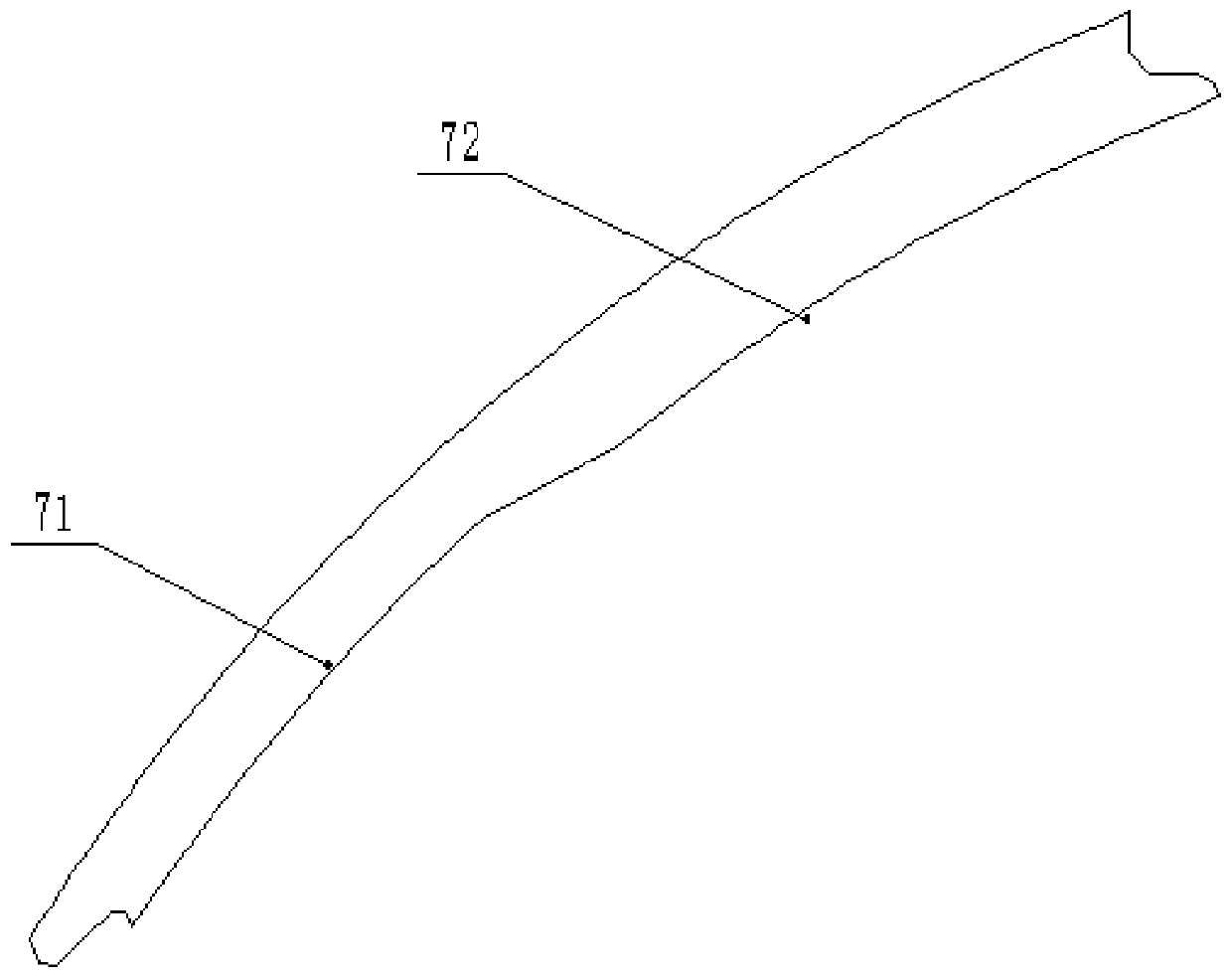

[0021] Such as figure 1 , figure 2 As shown, a rotary thin-walled can body forming device described in the embodiment of the present invention includes a turntable 5, a coaming plate 7 located above the turntable 5, a large gear 3 fixed below the turntable 5, and a Jacking track 2, tank clamping mechanism 6 and rotary jacking mechanism 4; turntable 5 is connected to the reduction motor through the power shaft and flange 1 and rotates clockwise, and positioning holes 51 ( see Figure 5 ), the coaming 7 is divided into an inlet and outlet section 71 and a processing section 72 according to the thickness of the inner wall, and the processing section 72 is thicker (see image 3 ), the clamping mechanism 6 includes a rotating shaft 65 fixed on the rotating disk 5, two clips 66 that rotate relative to the rotating shaft 65 and are equipped with torsion springs, a movable shaft 62 that drives the rotation of the clip 66, and the movable shaft 62 is built in and fixed on the The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com