Slab caster crystallizer copper plate and using method thereof

A mold copper plate and slab continuous casting machine technology, applied in the field of metallurgical equipment, can solve problems such as differences in the growth of billets and shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

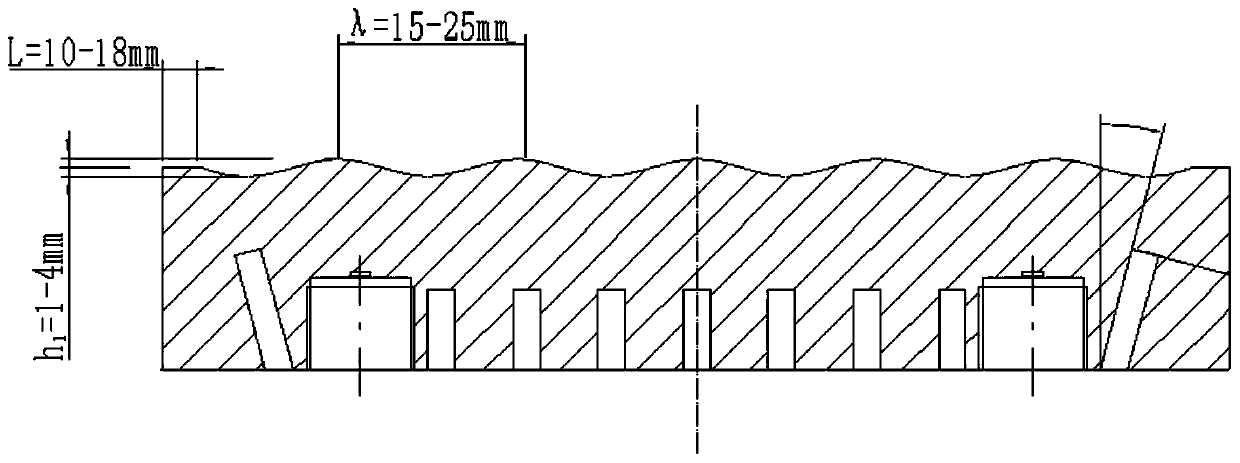

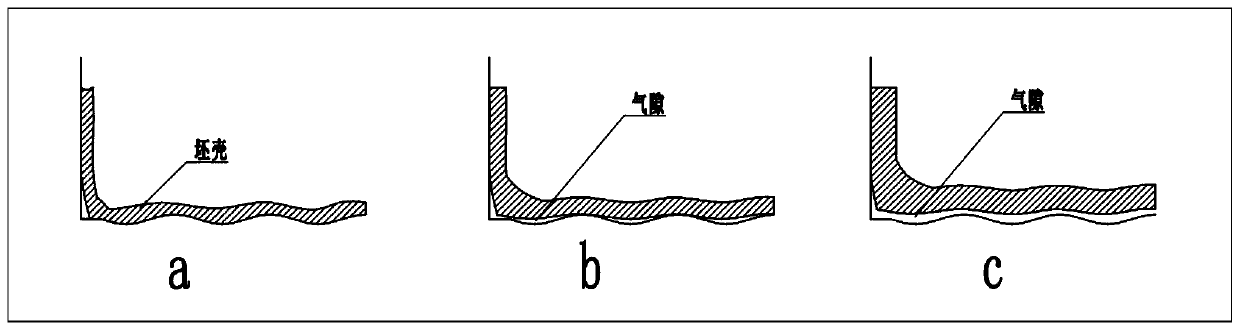

[0027] see figure 1 , a slab continuous casting machine crystallizer copper plate, mainly uses a wave-shaped copper plate to facilitate the flow of liquid mold slag in the crystallizer into the gap between the copper plate and the billet shell, filling the air gap, so that the heat conduction between the billet shell and the copper plate It can be completed according to the design requirements to lubricate the copper plate wall and reduce the wear of the billet shell on the copper plate surface. The billet shell is always kept close to the copper plate wall under the static pressure of the molten steel. Due to the wavy surface, it can prevent shrinkage in the direction of the narrow surface.

[0028] 1) The surface of the copper plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com