A rotary positioning device

A positioning device and positioning pin technology, used in positioning devices, large fixed members, manufacturing tools, etc., can solve the problems of difficult to ensure processing quality of combined fixtures, unsuitable for mass production, long tooling preparation cycle, etc., to improve processing quality and Efficiency, simple processing technology scheme, lightening effect of light work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better illustrate the present invention, it will be described in detail below in conjunction with the accompanying drawings.

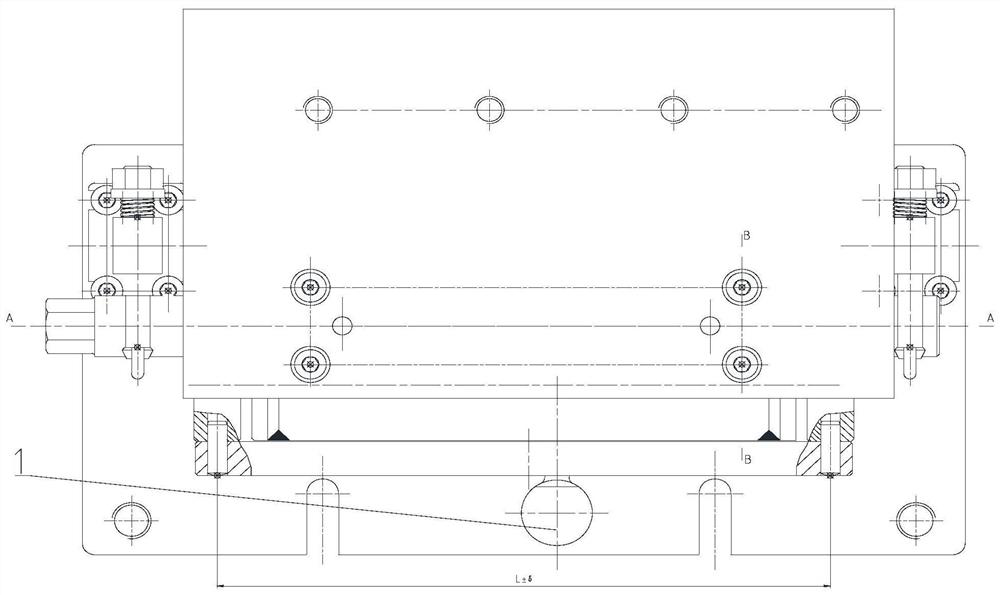

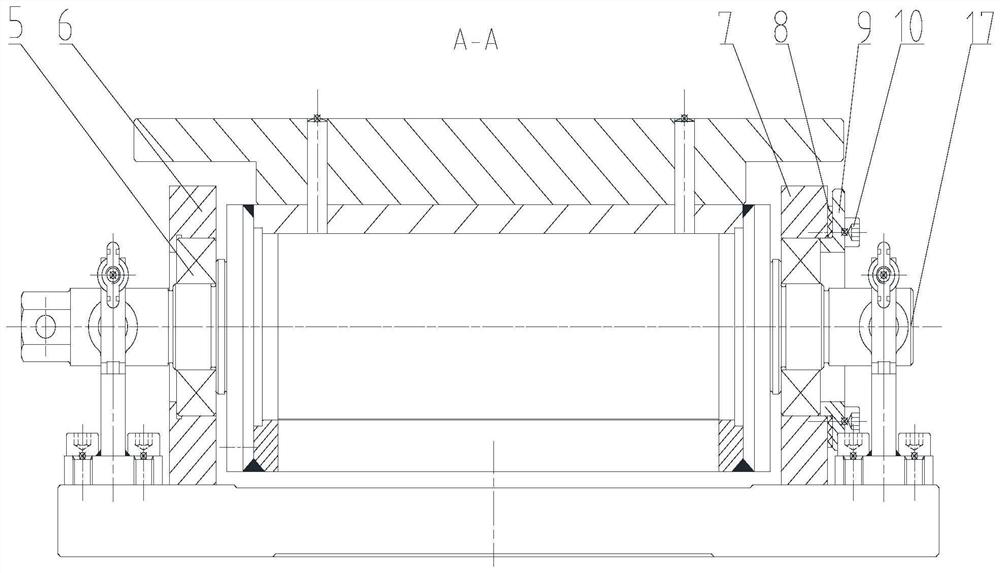

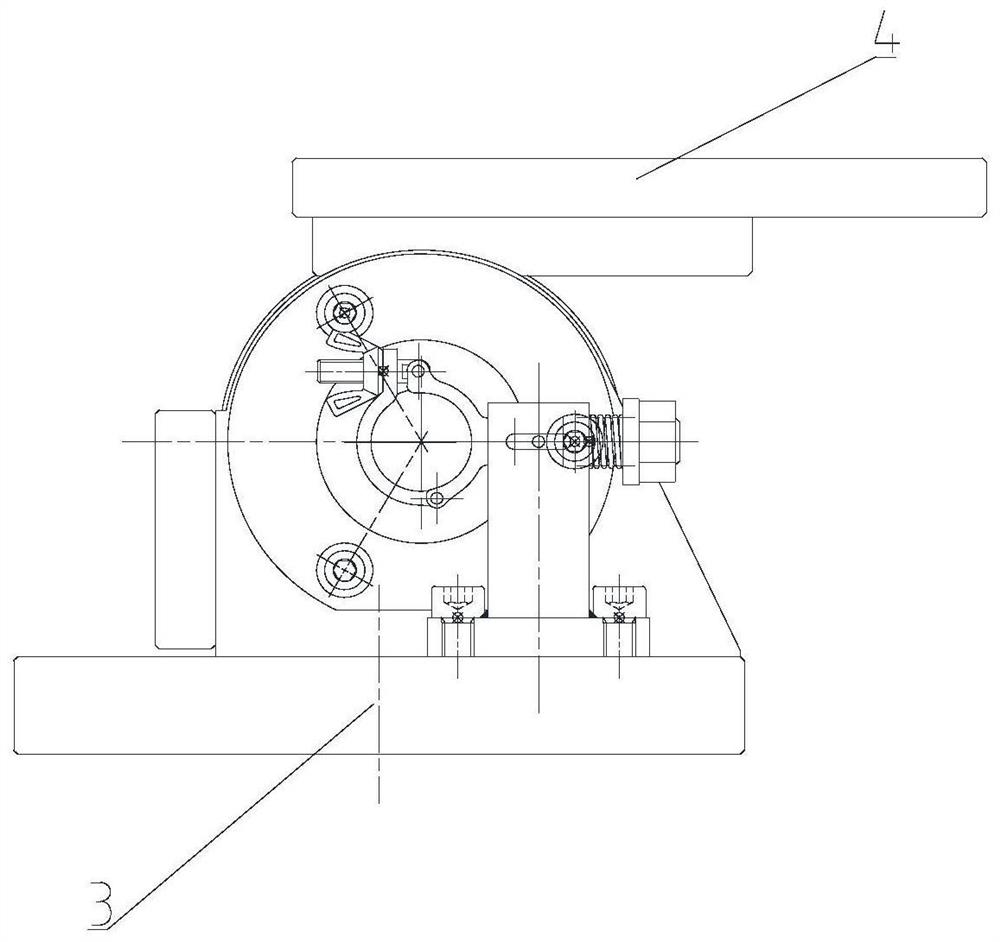

[0029] see figure 1 , figure 2 , Figure 5 , which is a structural schematic diagram and structural implementation of the present invention. The structure includes positioning pin 1, bottom plate 3, product placement plate 4, left support plate 6, right support plate 7, limit assembly, clamp assembly 11, positioning panel 12, roller assembly 17; left support plate 6, right support After the plates 7 are mounted on the two ends of the drum assembly 17 respectively, the left support plate 6 and the right support plate 7 are fixed on the base plate 3, and the positioning panel 12 is installed on the vertical surface of one side of the left support plate 6 and the right support plate 7, The product placement plate 4 is installed on the plane P of the drum assembly 17, and a clamp assembly 11 is fixedly installed at both ends of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com