Multi-nozzle side gate hot runner system

A technology of hot runner and side gate, which is applied in the field of hot runner system of side gate of multi-head nozzle, can solve the problem of low temperature at the end of the gate core of multi-head nozzle, reduce heat loss, reduce heat dissipation, and reduce contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

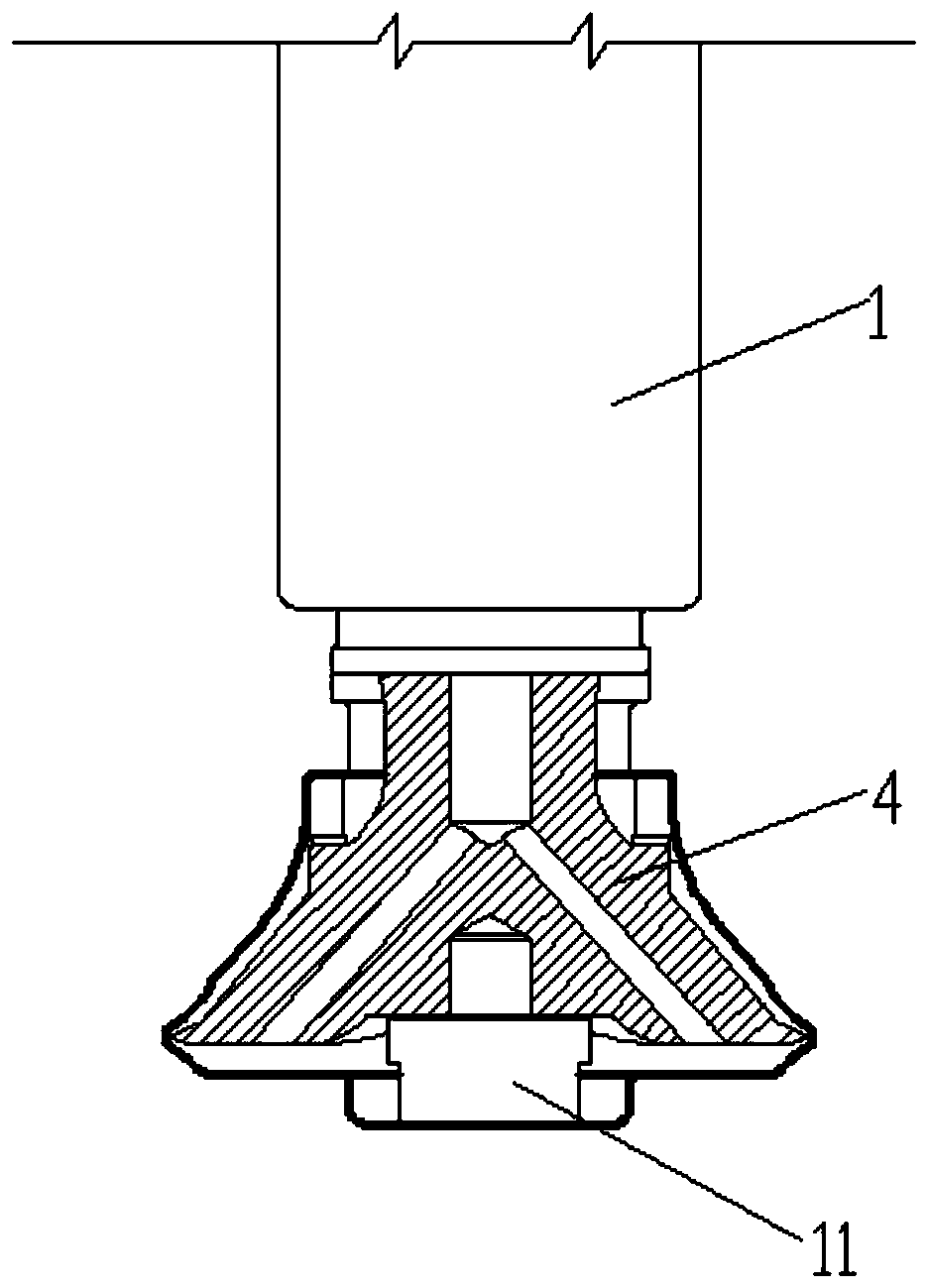

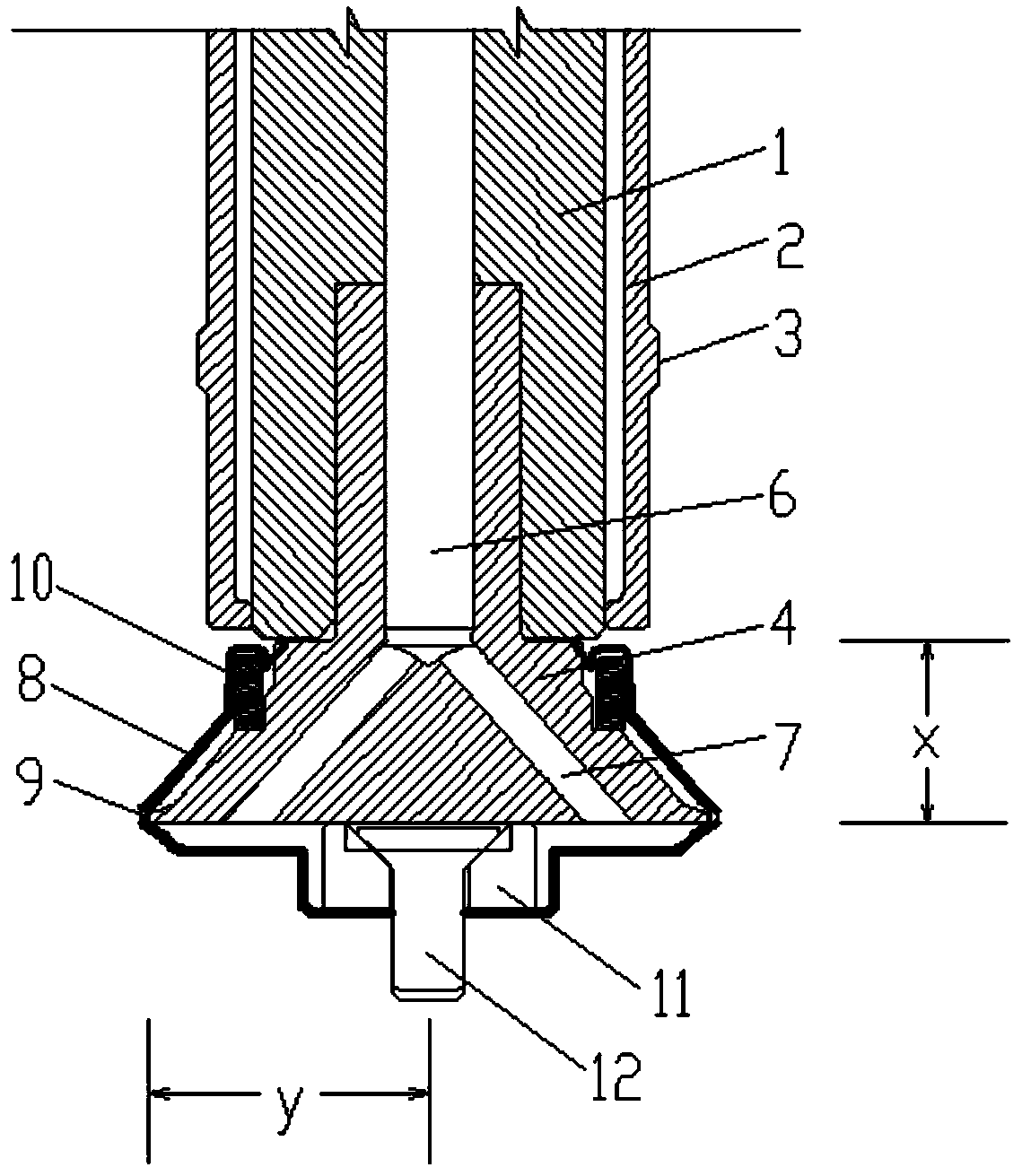

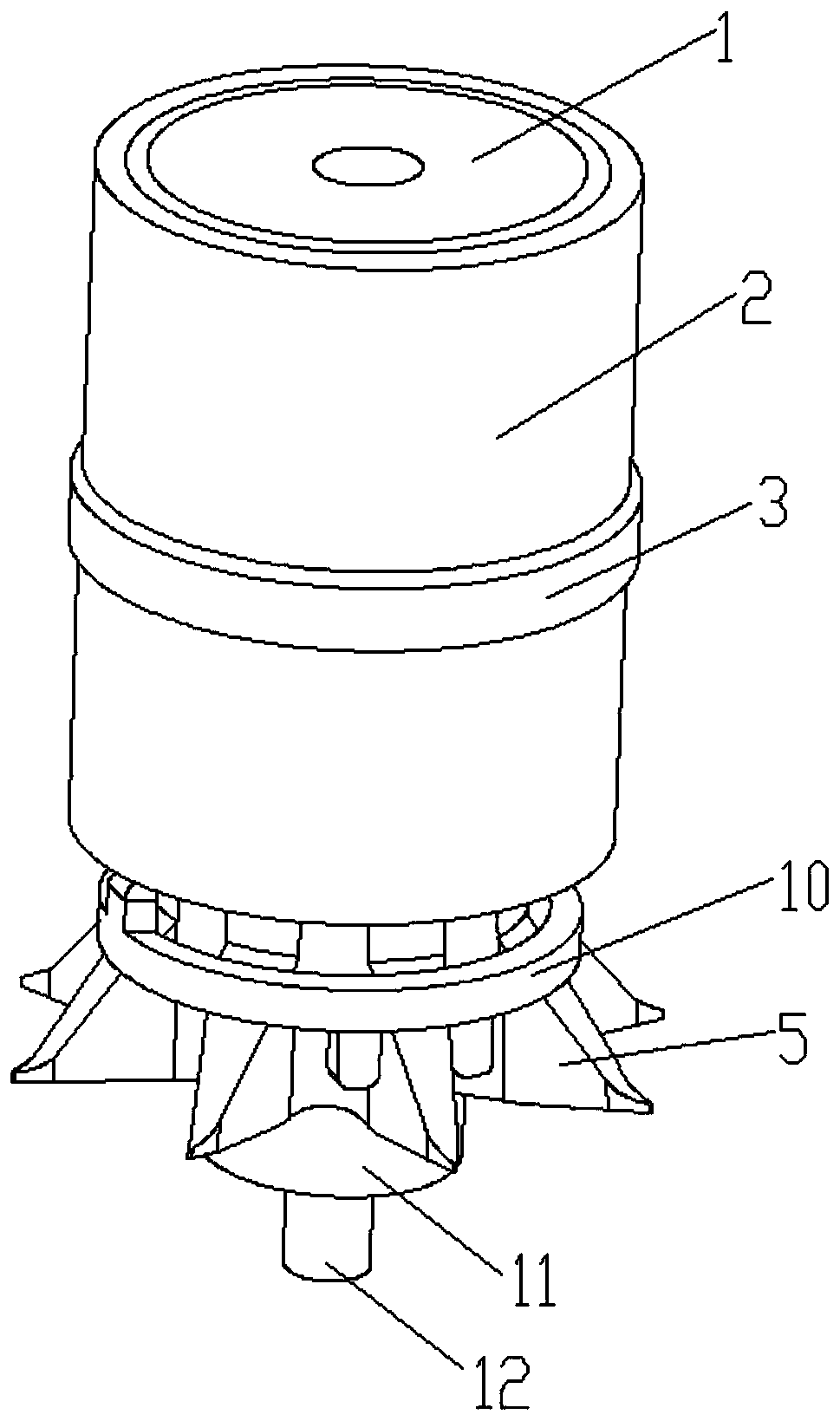

[0019] Such as figure 2 , image 3 As shown, a multi-head nozzle side gate hot runner system is used to be installed in the mold. The main body 1 coaxially arranges the multi-head nozzle gate core 4, the positioning ring 10 for fixing the multi-head nozzle gate core 4 and the support adjustment meson 11.

[0020] The outer wall of the heat-insulating rubber bushing 2 has a protruding and ring-shaped mold sealing surface 3. The radial section of the heat-insulating rubber bushing 2 is a pair of symmetrical C-shaped, and the inner wall has two upper and lower sides. The end is in interference fit with the outer wall of the main body 1 of the flow channel, and the middle part of the inner wall is in clearance fit with the main body 1 of the flow channel.

[0021] The multi-head sprue core 4 has eight nozzle heads 5 that extend outward and are evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com