Automatic octagonal system production equipment for paper box production

A production equipment, Bafang technology, applied in papermaking, paper/cardboard containers, box making operations, etc., can solve the problems that the pressing mechanism cannot be adjusted, occupies a large space area, and is dangerous, and prevents manual access and expansion. Scope of use, effect of avoiding trauma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

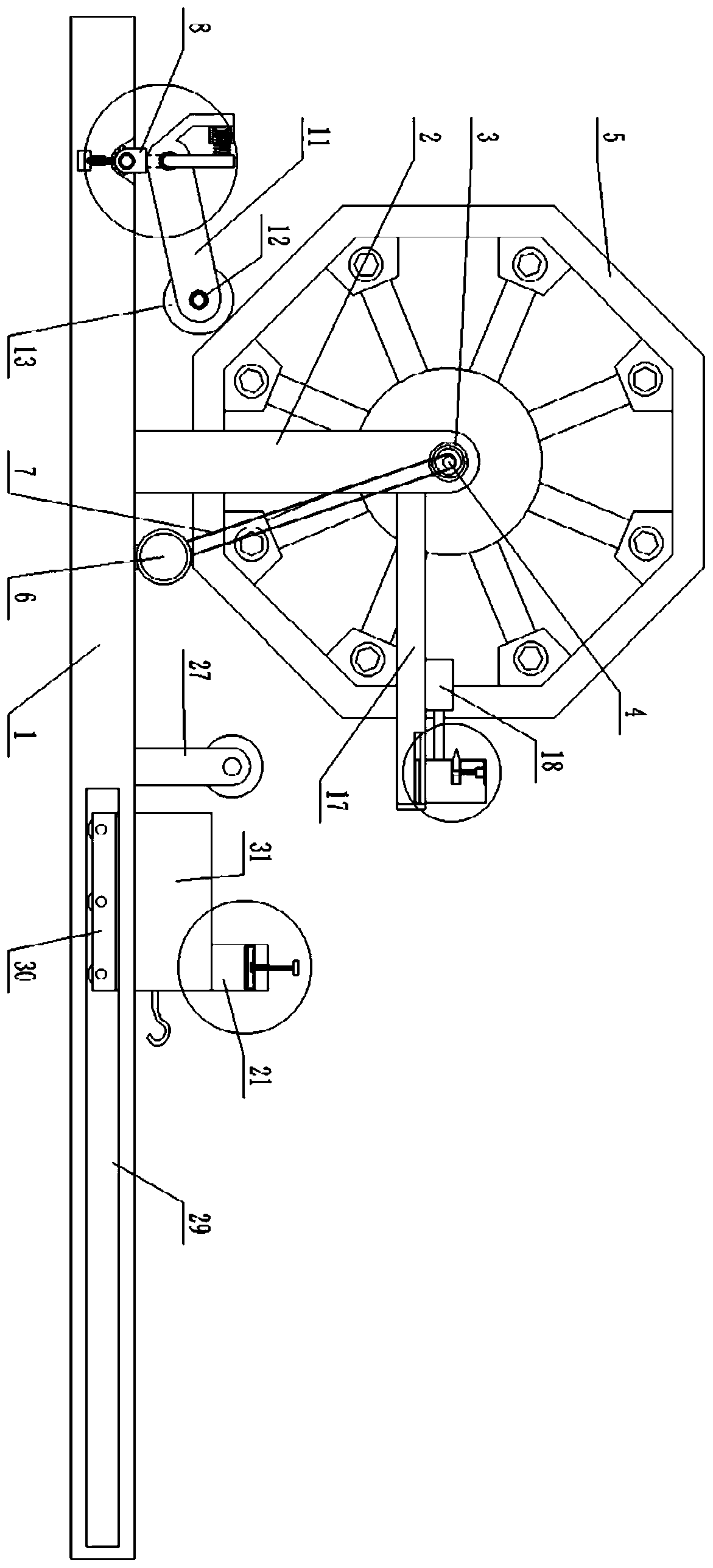

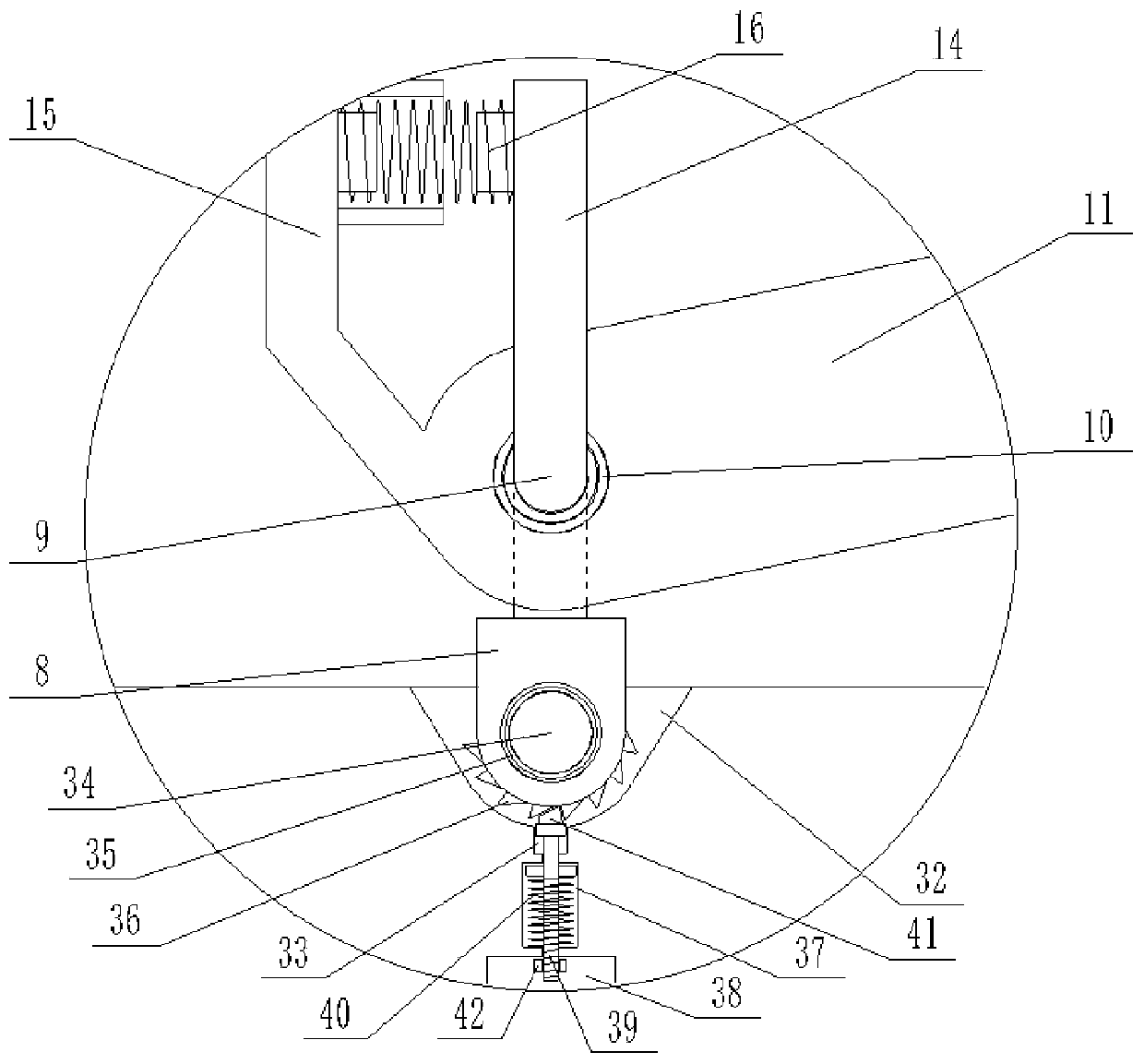

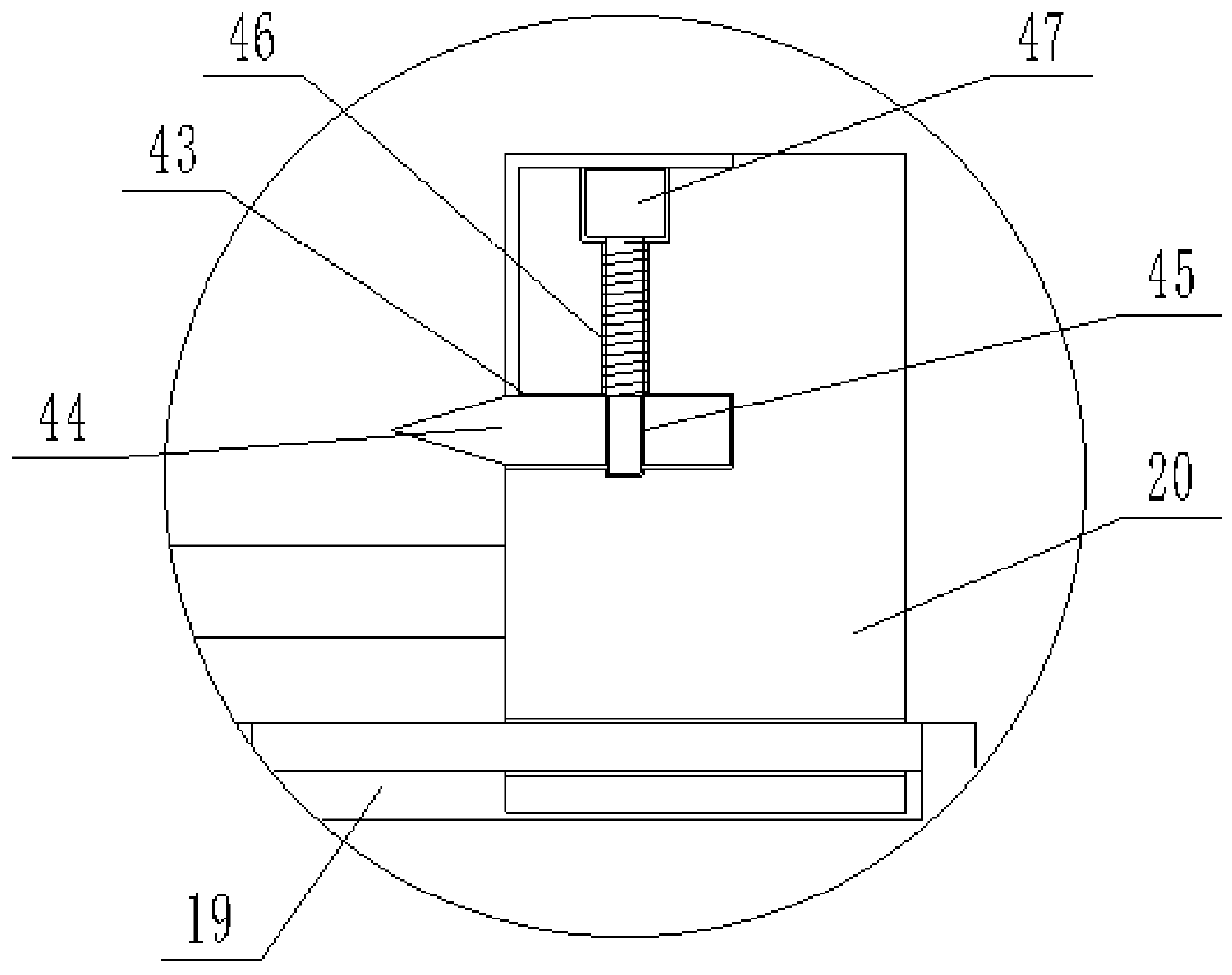

[0038] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7As shown, a kind of production equipment of the automatic Bafang system for carton production includes a bottom plate 1, a connecting rod 2, a bearing A3, a shaft A4, a Bafang frame 5, a motor 6 and a belt 7, and the lower ends of the connecting rod 2 are respectively connected to the The front and rear sides of the upper surface of the bottom plate 1, the bearing A3 is fixedly embedded in the upper end of the connecting rod 2, the shaft rod A4 is fixedly sleeved in the bearing A3, and the front and rear sides of the octagonal frame 5 are respectively connected to the upper end of the connecting rod 2. The shaft A4 is connected, the motor 6 is connected to the upper surface of the bottom plate 1, the belt 7 is respectively set on the output end of the motor 6 and the shaft A4, and the upper surface of the bottom plate 1 is provided with a pressure tightening mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com