Vanadium slag continuous vanadium solution leaching device

A leaching and solution technology, applied in the field of vanadium slag continuous leaching vanadium solution device, can solve the problems of long time and complicated procedures, and achieve the effect of improving the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

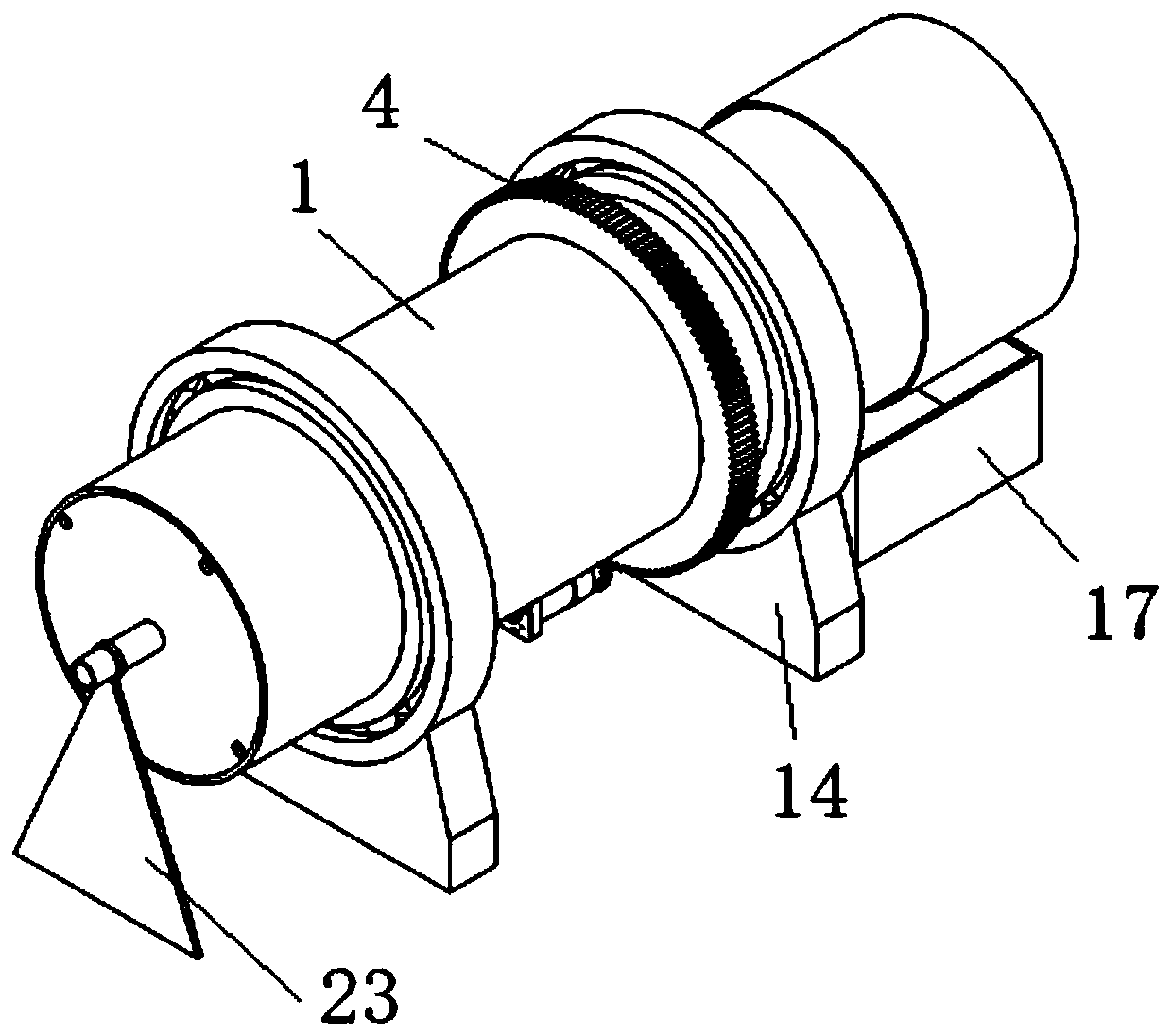

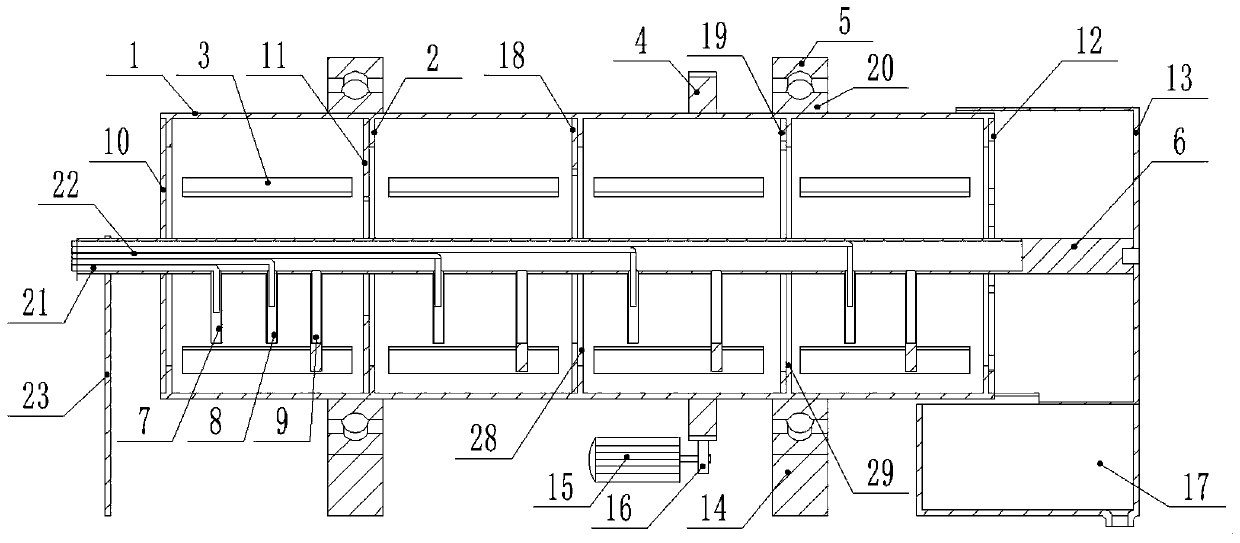

[0037] Such as figure 1 and 2 As shown, a vanadium slag continuous leaching vanadium solution device includes a rotary cylinder 1, the outer edge of the rotary cylinder 1 is provided with a rotating support assembly, and the outer edge of the rotary cylinder 1 on one side of the rotary support assembly is provided with a The driving assembly used to drive the rotation of the rotary cylinder 1; one end of the rotary cylinder 1 is provided with a discharge port 26, and the interior of the rotary cylinder 1 is provided with a cavity, and a central shaft is arranged in the cavity along the axial direction 6. There are several baffles arranged at intervals in the cavity, and the middle part of the baffle is provided with a through hole 24 sleeved on the central shaft 6, from the direction away from the discharge port 26 to the direction close to the discharge port. The aperture of the via hole 24 on the baffle plate in the direction of the material outlet 26 increases successively...

Embodiment 2

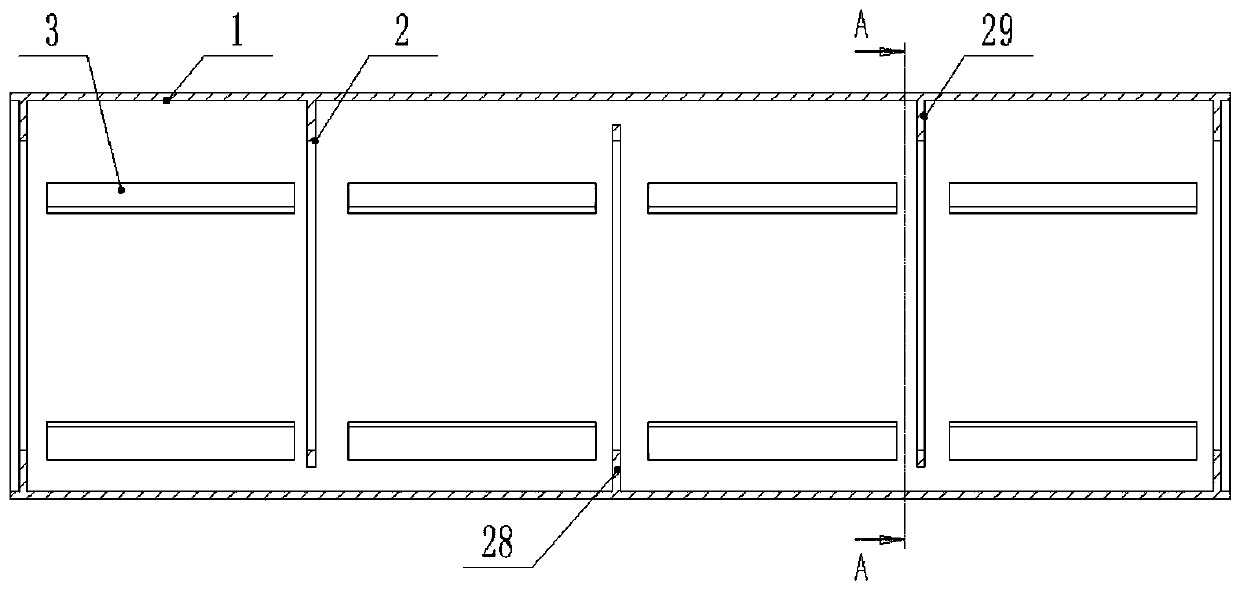

[0044] Such as image 3 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the rotating cylinder 1 includes a front baffle 10, a rear baffle 12, and a continuous side wall sealingly connected between the front baffle 10 and the rear baffle 12. The discharge port 26 is opened on the rear baffle 12, and the discharge port 26 is fan-shaped. Such as Figure 5 As shown, there are 4 discharge ports 26 and the central angles of the 4 fan-shaped discharge ports 26 are all set towards the center of the tailgate 12. Offer 4 fan-shaped discharge openings 26 on the rear baffle plate 12, be convenient to the vanadium solution to flow out, because the rotary cylinder 1 is always rotating, can guarantee the discharge rate of the rotary cylinder 1 when rotating like this.

Embodiment 3

[0046] Such as figure 2 As shown, this implementation is further optimized on the basis of Embodiment 2. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the front baffle 10 and the center of the rear baffle 12 are provided with a through central hole, and one end of the central shaft 6 passes through the central hole of the front baffle 10 and is connected with a bracket 23 arranged outside the cavity, and the central shaft 6 is connected to the front baffle. The central hole of the plate 10 is connected with the sealing shaft, the other end of the central shaft 6 runs through the central hole of the tailgate 12 and is connected with the tail cover 13 sleeved outside the rotating cylinder 1, and the central shaft 6 is connected to the center of the tailgate 12. Bore sealed shaft connection. This can ensure that the rotary cylinder 1 is rotating, and the central shaft 6 remains motionless, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com