Adjustable steel bar positioning and point distributing device

An adjustable, steel bar technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems that affect the quality of steel bar binding and construction efficiency, the accuracy of manual marking positions cannot be guaranteed, and easy to produce deviations, etc., to achieve improvement Improve the quality of steel bar binding, improve the accuracy of marking, save labor and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

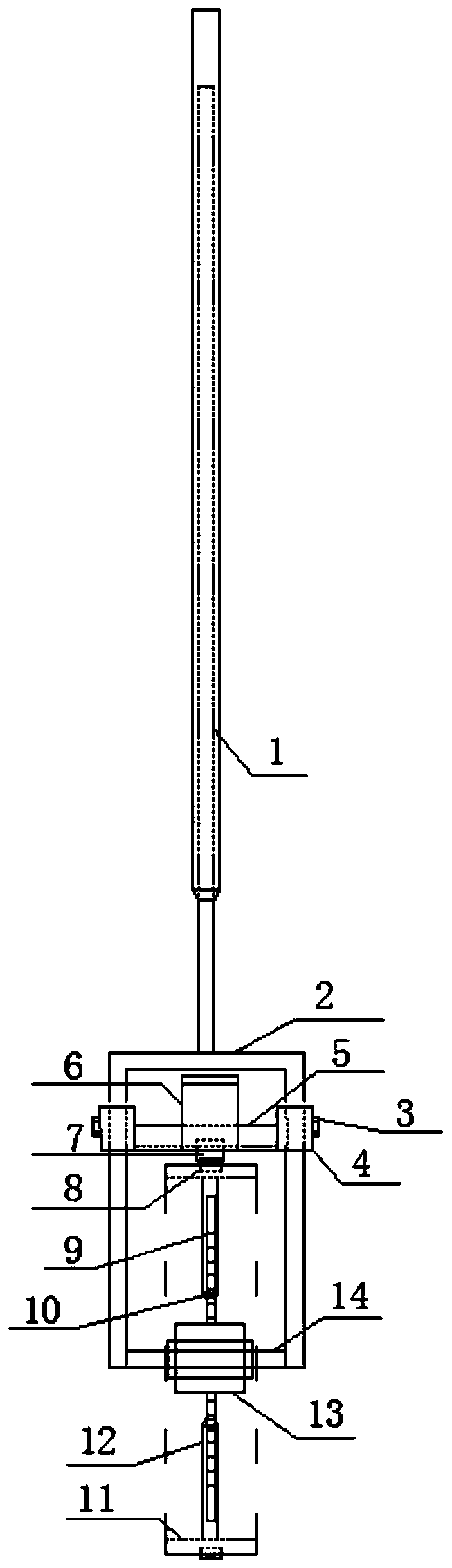

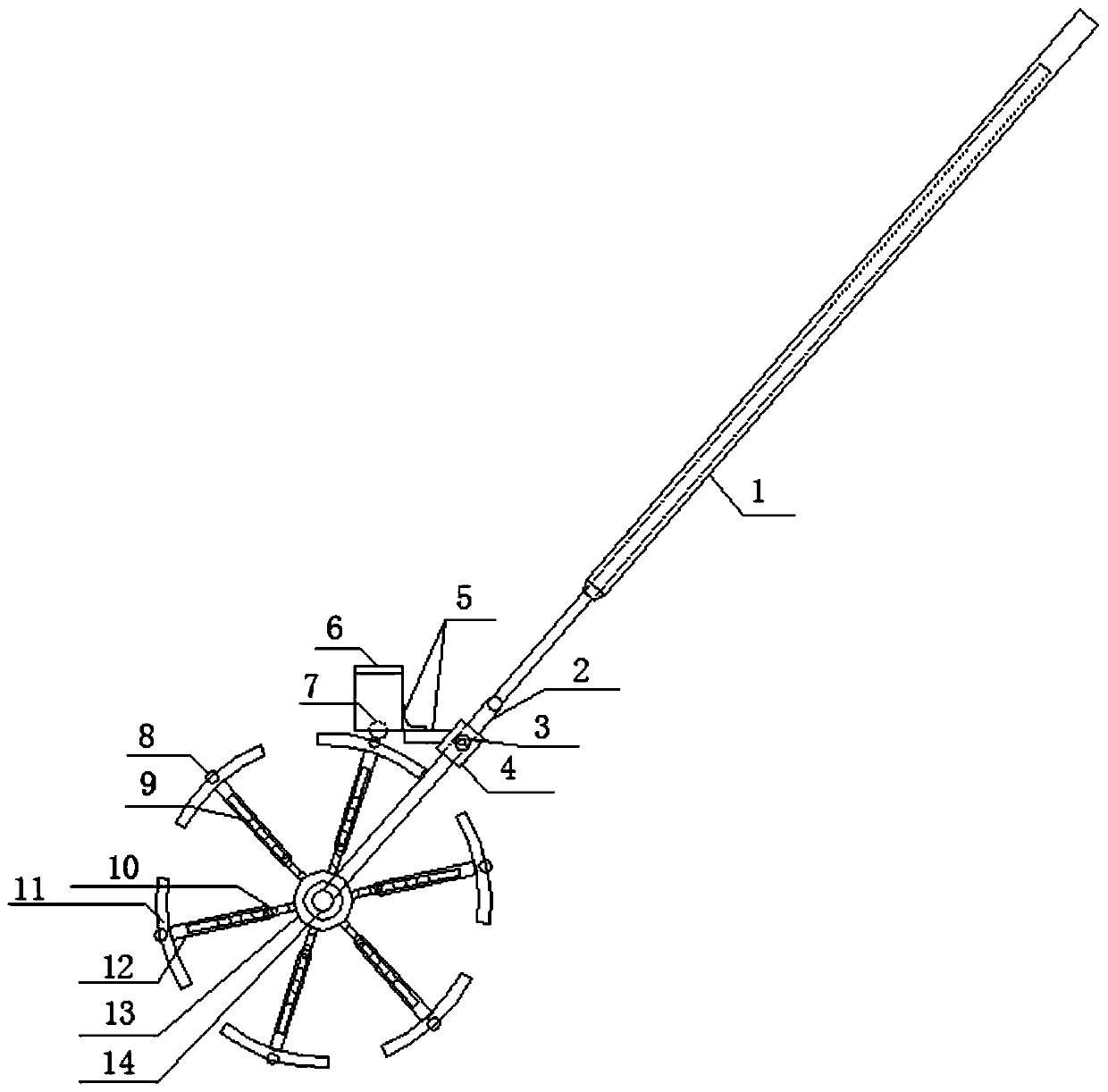

[0019] Such as figure 1 and figure 2 As shown, the adjustable reinforcing bar positioning device of the present invention has its main components as follows: 1-telescopic rod, 2-fork frame, 3-fixing bolt, 4-sliding sleeve, 5-fixed frame, 6-ink storage box, 7- - ink stick, 8-brush stick, 9-scale scale, 10-positioning lock nut, 11-brush table, 12-rotating telescopic rod, 13-rotating disc, 14-rotating bearing;

[0020] The telescopic rod 1 is telescopic, and the operator can adjust the length according to needs; the lower end of the telescopic rod 1 is connected with the fork frame 2 .

[0021] The fork frame 2 is a rod-shaped member connected in three sections, and the lower ends of the rods on both sides are perforated, and the rotating bearing 14 is fixed at the hole on the fork frame and is detachable.

[0022] There are two sliding sleeves 4, which are placed on the rods on both sides of the fork frame 2 and can slide up and down. The position of the sliding sleeve 4 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com