Magnetic drive pump with pump shaft axial displacement monitoring device

A monitoring device and axial displacement technology, applied in pump device, pump control, measuring device and other directions, can solve the failure of the impeller and the pump cover seal ring, the observation of the axial movement of the pump shaft, and the axial fit of the rotor. and problems such as the increase in the amount of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

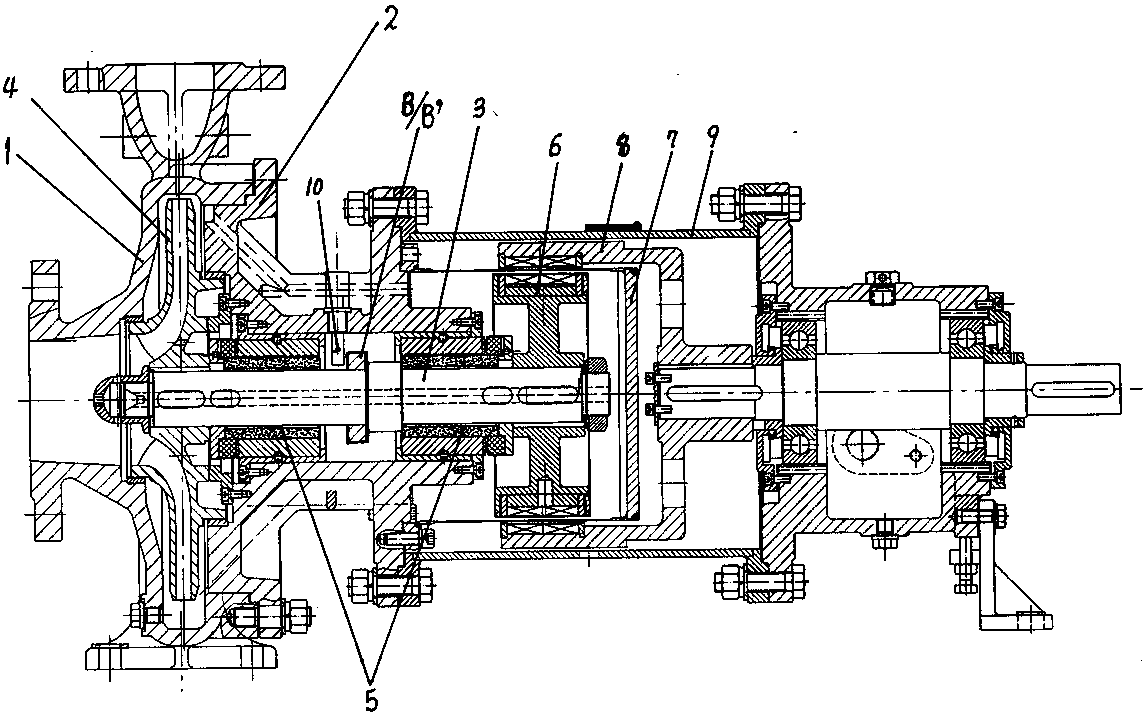

[0007] The magnetic pump of the present invention includes a pump body 1, a pump cover 2, a pump shaft 3, an impeller 4, a main shaft sliding bearing device 5, an inner magnetic rotor 6, an isolation sleeve 7, an outer magnetic rotor 8, and a sleeve bracket 9. An eddy current sensor probe 10 is installed on the pump cover 2, a collar B' is fixed on the shoulder of the pump shaft 3, and the head of the eddy current sensor probe 10 goes deep into the side of the collar B' The parts are arranged at a certain distance, and an eddy current sensor conversion device is arranged outside the magnetic pump body, and the eddy current sensor probe transmitter provided outside the pump body is connected with the eddy current sensor probe 10 signal wires.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap