Steam drying room for drying o-cyanobenzyl chloride

A technology of o-cyanobenzyl chloride and steam is applied in drying, drying machine, drying solid materials and other directions, which can solve the problems of poor working environment, large investment and high labor cost, and achieves simple structure, good drying effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

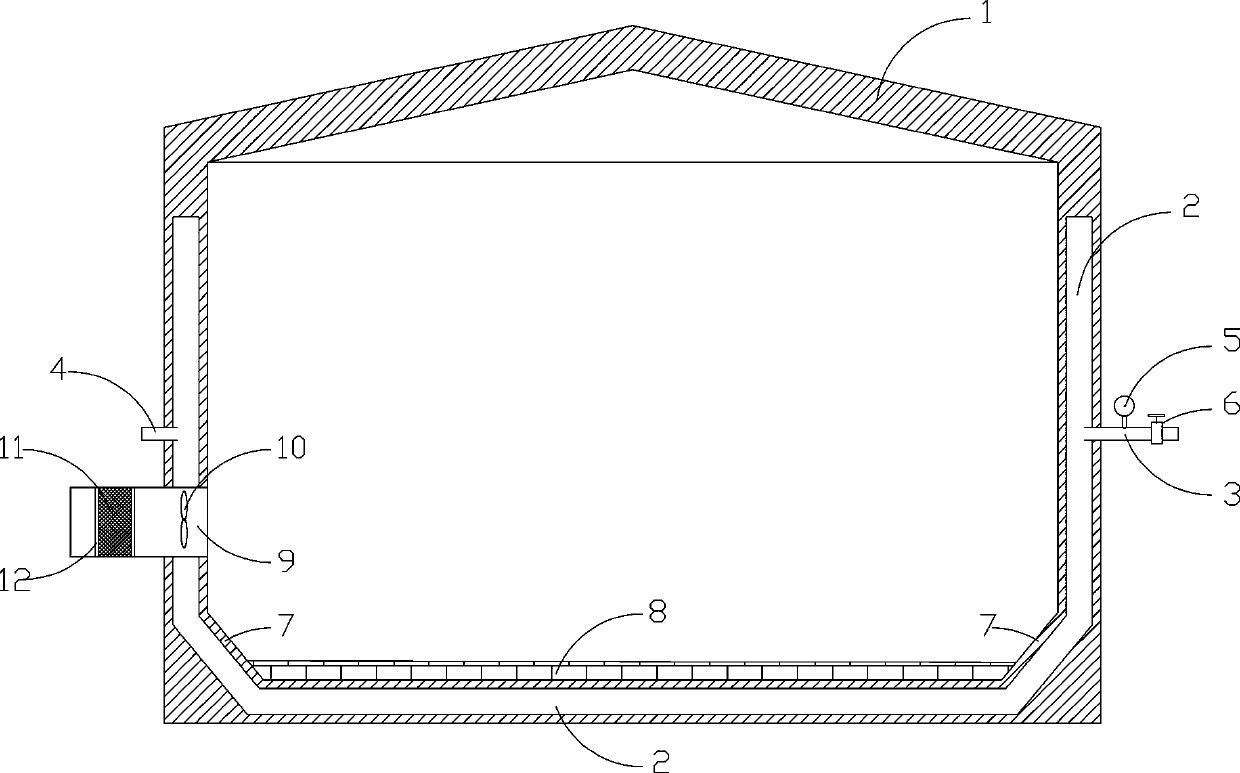

[0009] see figure 1 , a steam drying room for drying o-cyanobenzyl chloride has a room body 1, the left and right walls and the bottom of the room body 1 are provided with a sandwich structure 2 for feeding high-temperature steam, and The sandwich structure 2 is provided with a steam inlet 3 and a steam outlet 4, and a pressure gauge 5 and a ball valve 6 are installed on the pipeline where the steam inlet 3 is located, and the drying temperature in the room body 1 is adjusted by adjusting the opening of the ball valve 6; The left and right corners of the house body 1 are all provided with a slope structure 7, which is better than the current right-angled corner, so as to clean and charge the dried o-cyanobenzyl chloride; A layer of marble slabs 8 for storing o-cyanobenzyl chloride to be dried is laid; one side wall of the room body 1 is provided with an air exhaust port 9, and an air exhaust port 9 is installed at the air exhaust port 9. Air fan 10 and dust suction device.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap