Synchronous temperature measuring device based on additive manufacturing

A temperature measurement device and additive manufacturing technology, which is applied in measurement devices, thermometers, and heat measurement, etc., can solve the problems of complicated operation procedures, long temperature measurement operations, and inaccurate positioning of temperature measurement points, so as to improve positioning accuracy. , Improve the safety of use and the effect of improving the efficiency of temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

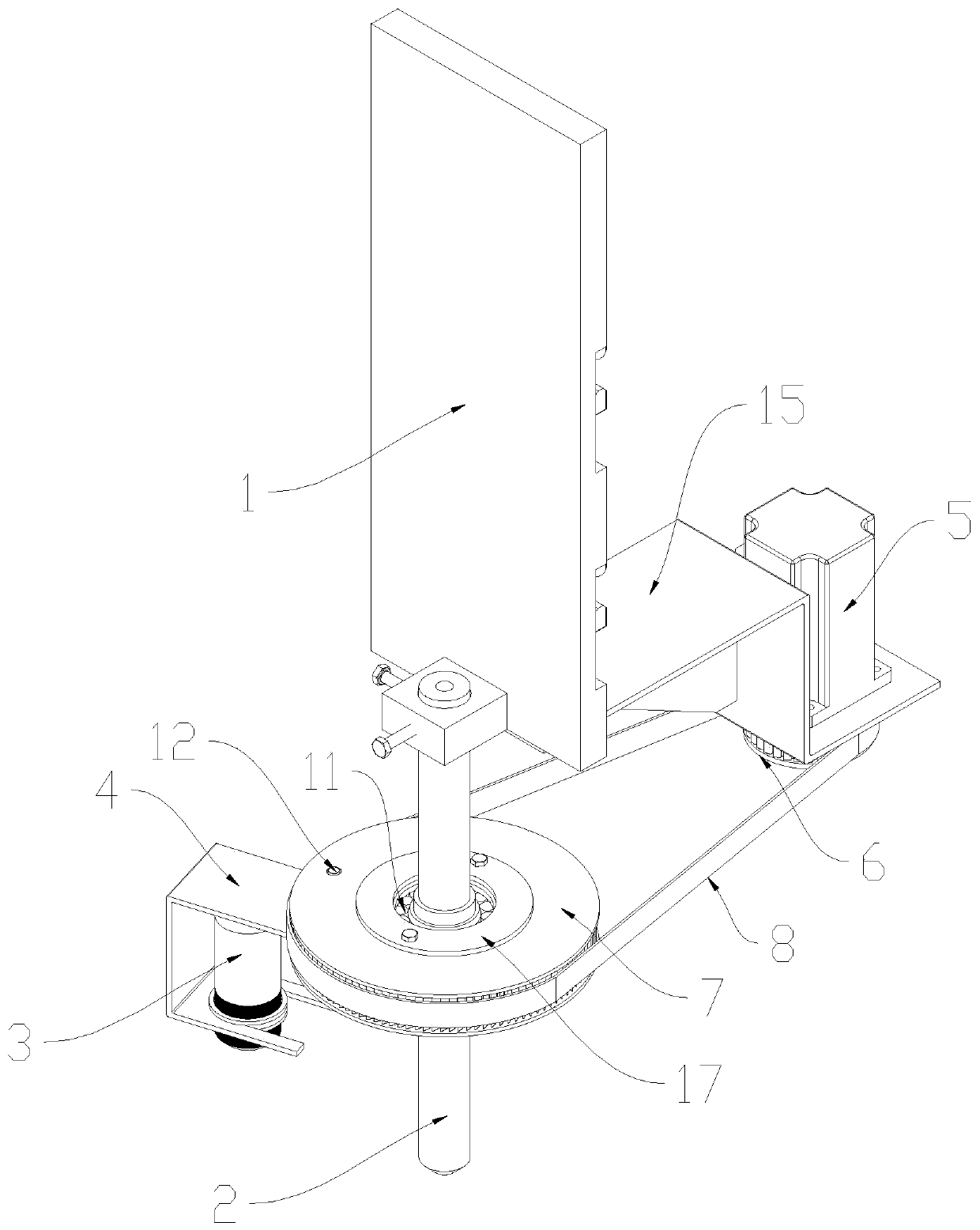

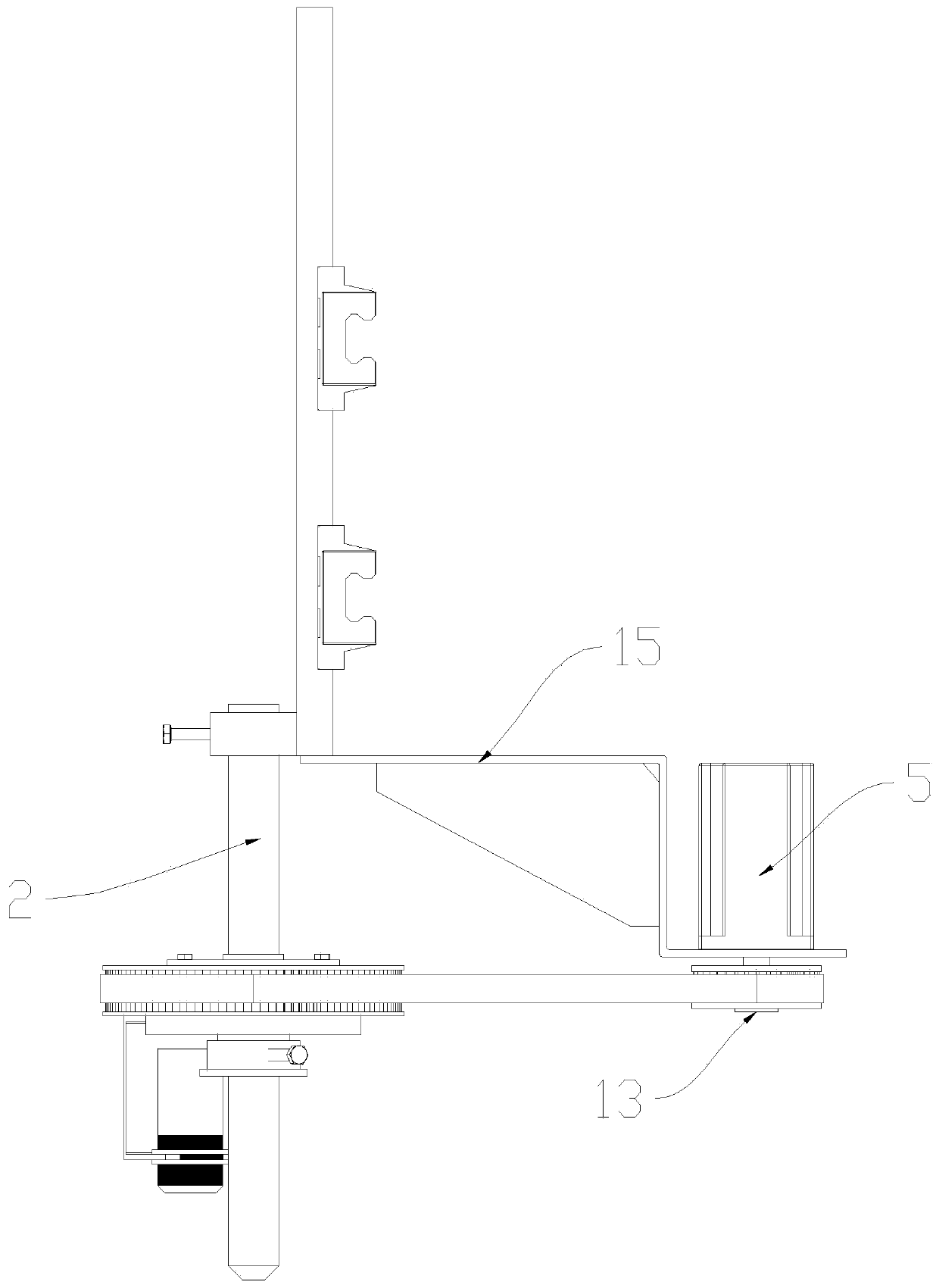

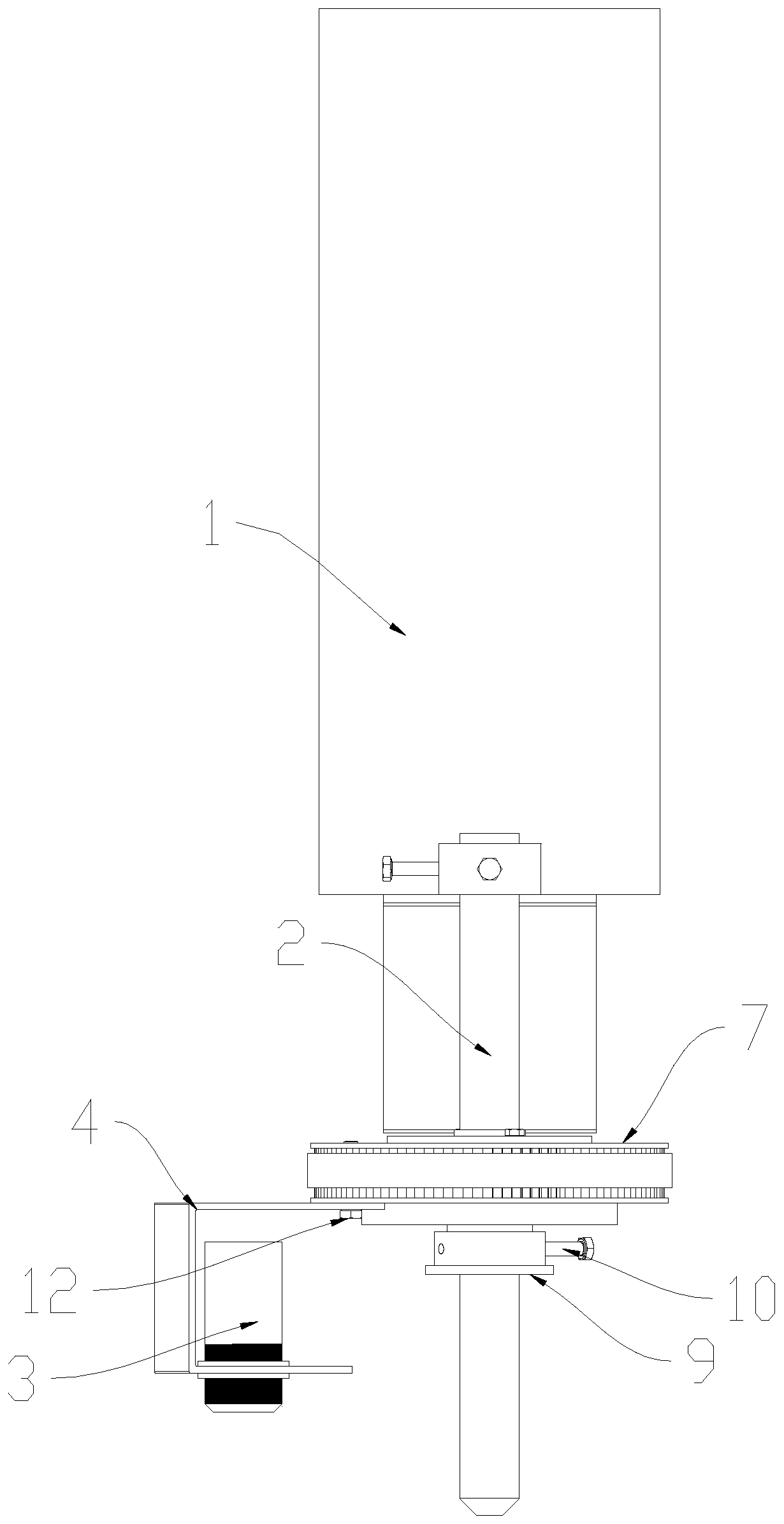

[0025] see Figure 1 to Figure 4 , a synchronous temperature measuring device based on additive manufacturing, including an equipment frame 1 and an arc welding torch 2 arranged on the equipment frame 1, and also includes a temperature measuring instrument 3 and a bracket 4, and the bracket 4 is installed on the arc welding torch 2, The thermometer 3 is arranged on the support 4 , and a rotation control mechanism for controlling the rotation of the thermometer 3 around the arc welding torch 2 is provided between the support 4 and the arc welding torch 2 .

[0026] Among them, see figure 1 and Figure 4 , the rotation control mechanism includes a motor 5, a small synchronous wheel 6 and a large synchronous wheel 7, the motor 5 is fixedly installed on the equipment frame 1, the output shaft of the motor 5 is connected to the small synchronous wheel 6, and the large synchronous wheel 7 is rotated and installed on the arc welding torch 2 Above, a synchronous belt 8 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com