Aero-engine main bearing residual life prediction method based on digital twinning

An aero-engine and life prediction technology, which is applied in the fields of electrical digital data processing, special data processing applications, biological neural network models, etc. , to achieve the effect of preventing major flight accidents and ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

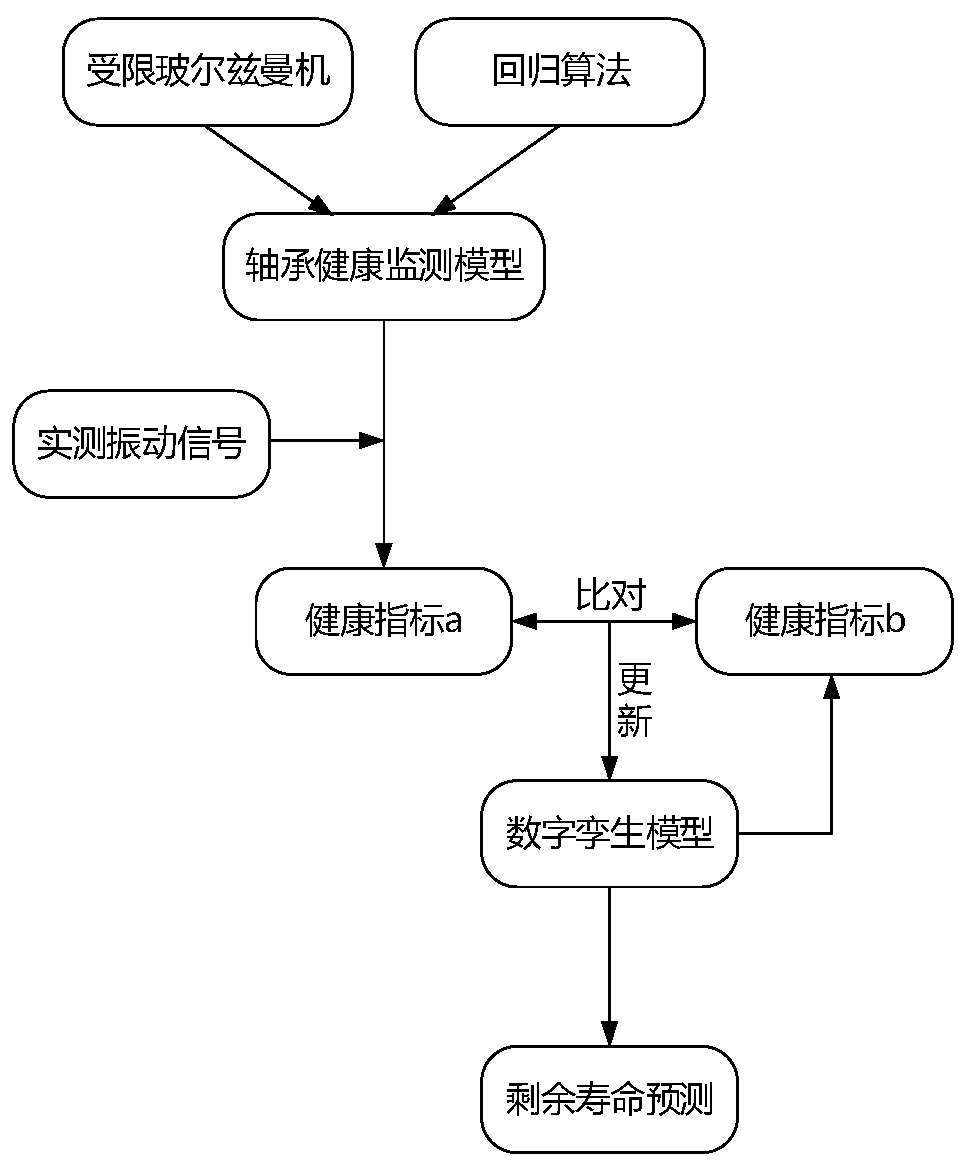

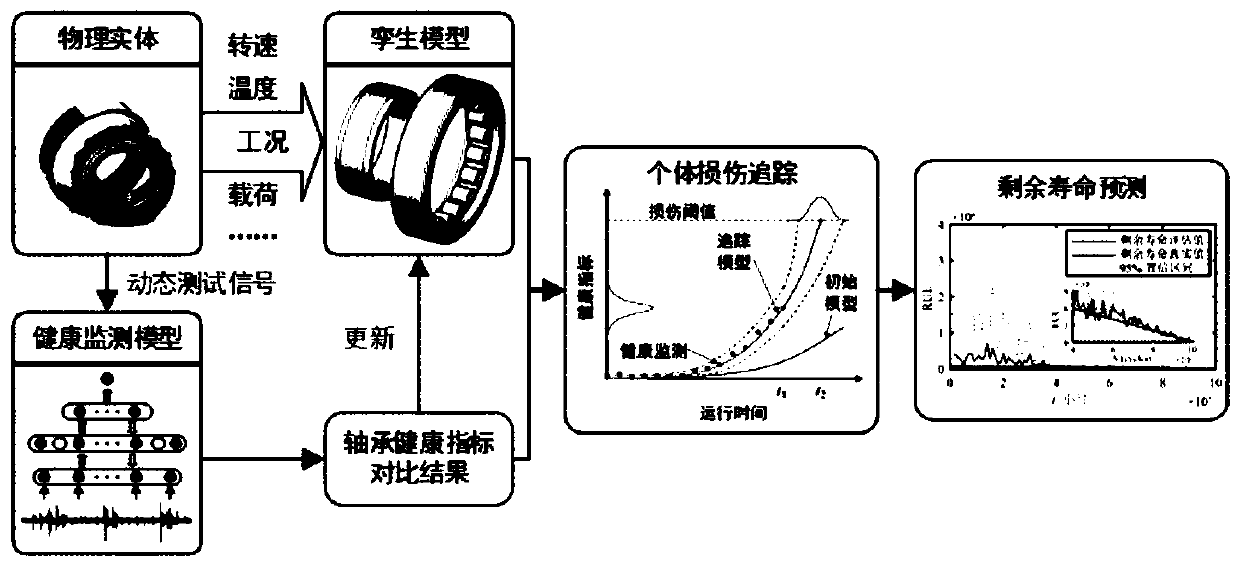

[0049] refer to figure 1 and figure 2 , the method for predicting the remaining life of an aero-engine main bearing based on digital twins proposed by the present invention includes the following steps:

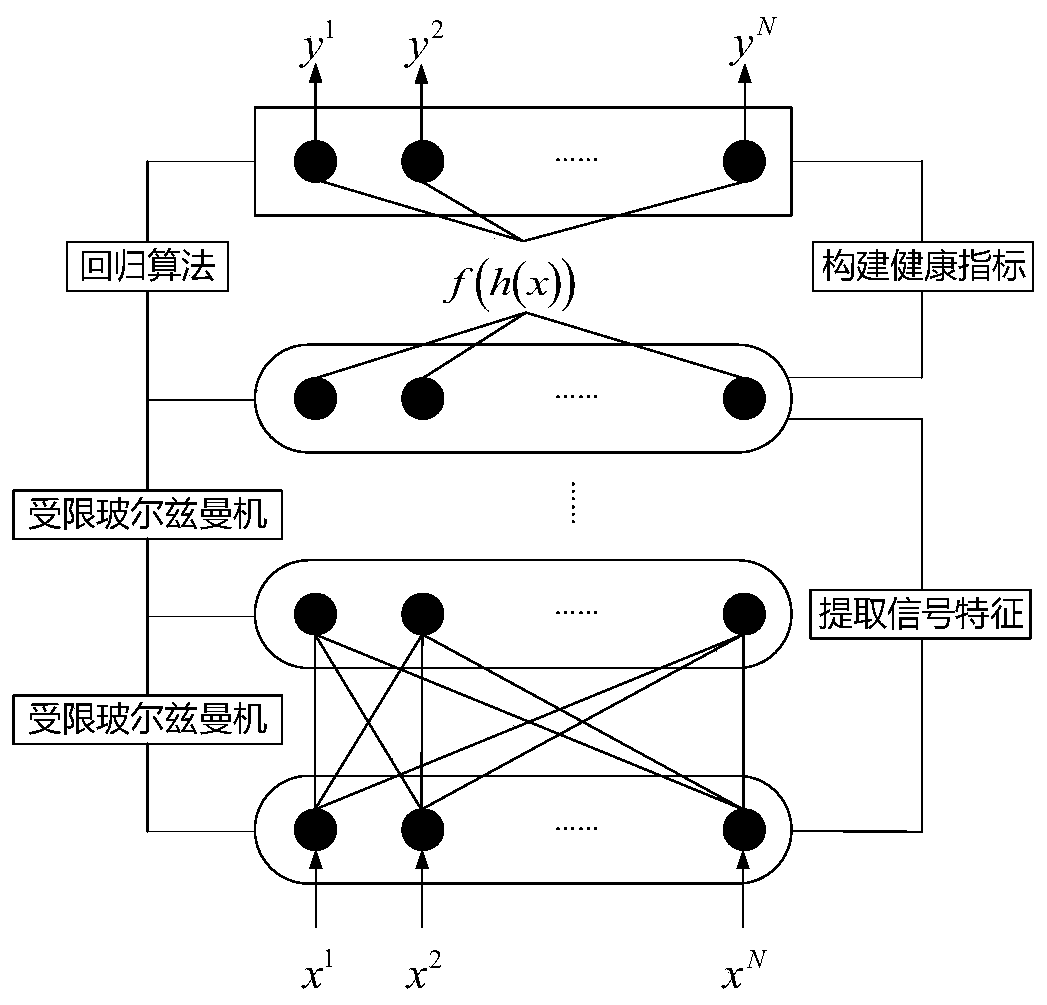

[0050] S1, using multiple restricted Boltzmann machine stacks to construct a deep neural network, and training the deep neural network through data samples, so that the deep neural network can detect the deep damage hidden in the vibration signal of the main bearing of the aeroengine The feature is extracted; the data sample comes from real experimental data, and the data points include vibration response, deep damage feature and aeroengine main bearing life; the deep damage feature includes but not limited to damage area and damage depth;

[0051] S2, use the deep neural network obtained in S1 to extract the deep damage features, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com