Cathode optical structure of miniature micro-focal-spot X-ray tube

An X-ray tube and optical structure technology, applied in X-ray tube cathode components, X-ray tube electrodes, X-ray tube components, etc., can solve problems such as weak anti-vibration ability and difficult processing of spiral wire, and achieve high strength Larger, simplify the difficulty of development and welding, and enhance the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described now in conjunction with accompanying drawing.

[0031] The invention provides a miniature cathode optical structure especially suitable for miniature X-ray tubes, which can achieve high focus on electrons under the condition of using straight cathode filaments or spiral cathode filaments, and can be used in a wide high voltage range of 20kV-50kV Within, the X-ray focal spot size can be made smaller than 300 microns. This cathodic optical structure not only enhances the anti-vibration ability of the micro X-ray tube, but also provides a technical approach for the development of high-end micro micro-focus X-rays, which enhances the application of the micro X-ray tube in high-resolution nondestructive testing.

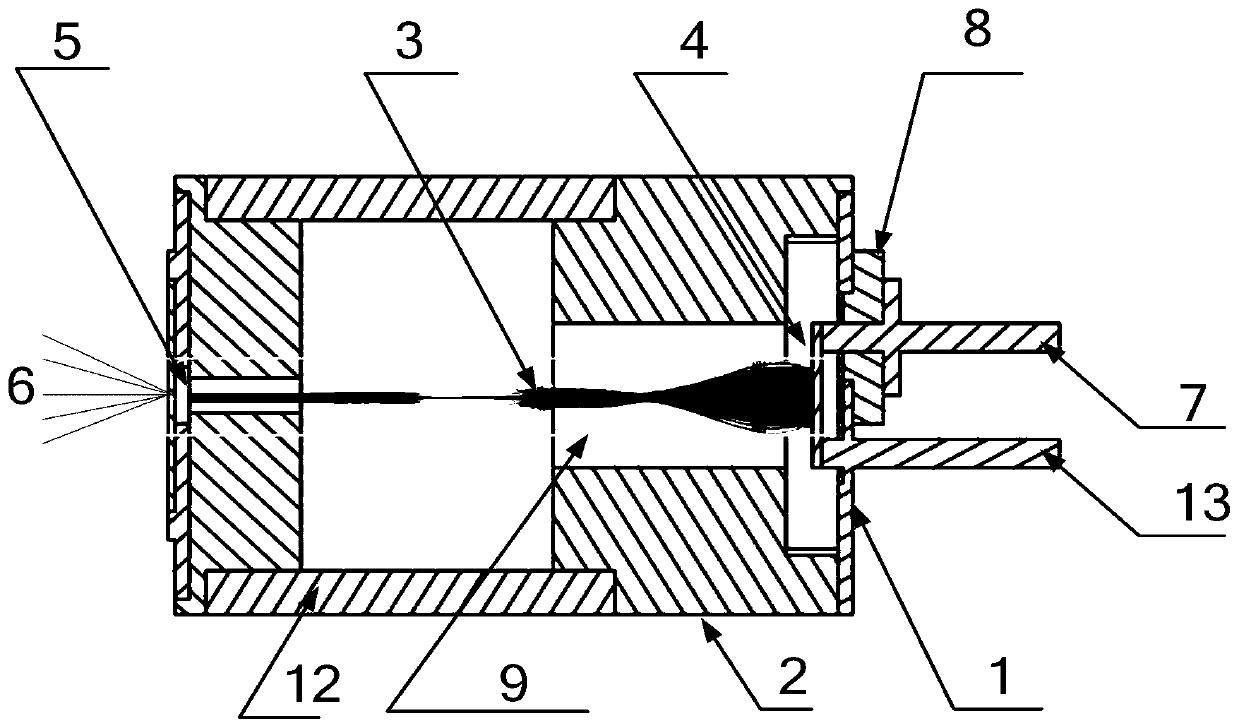

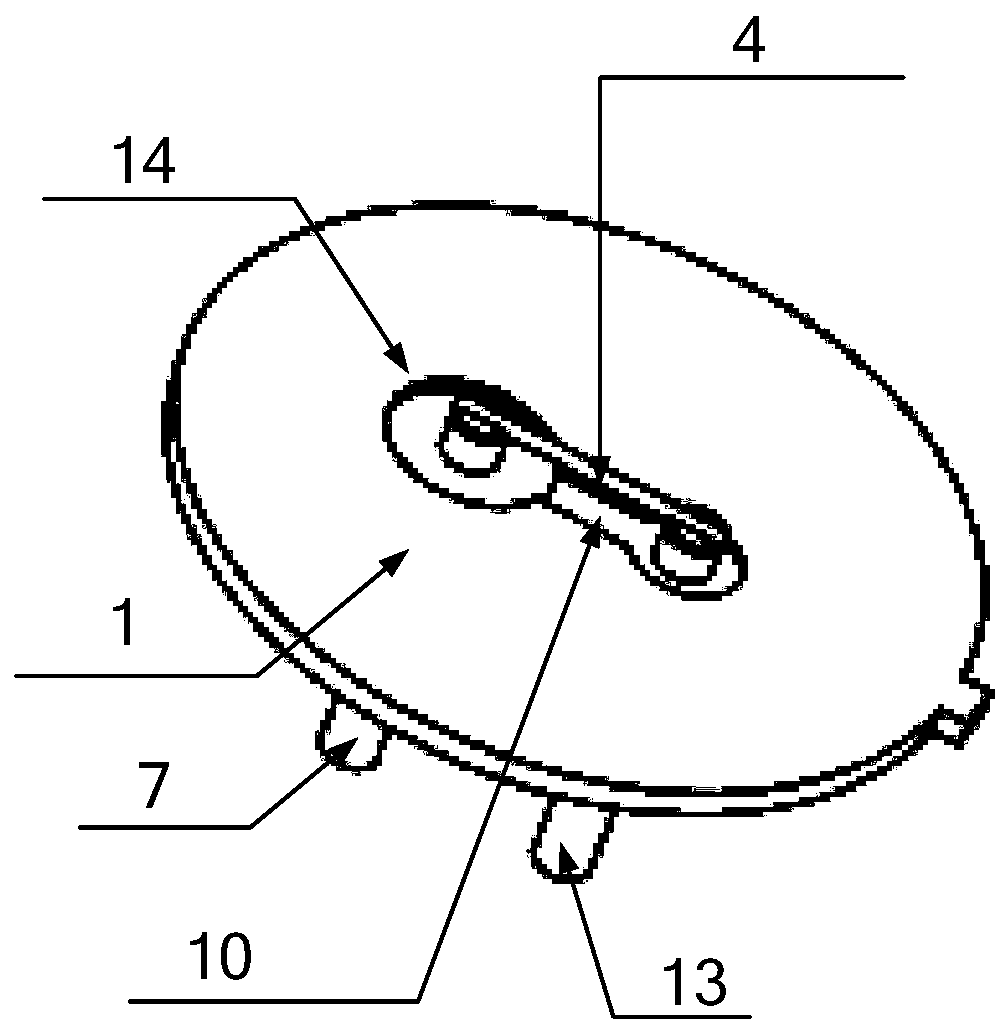

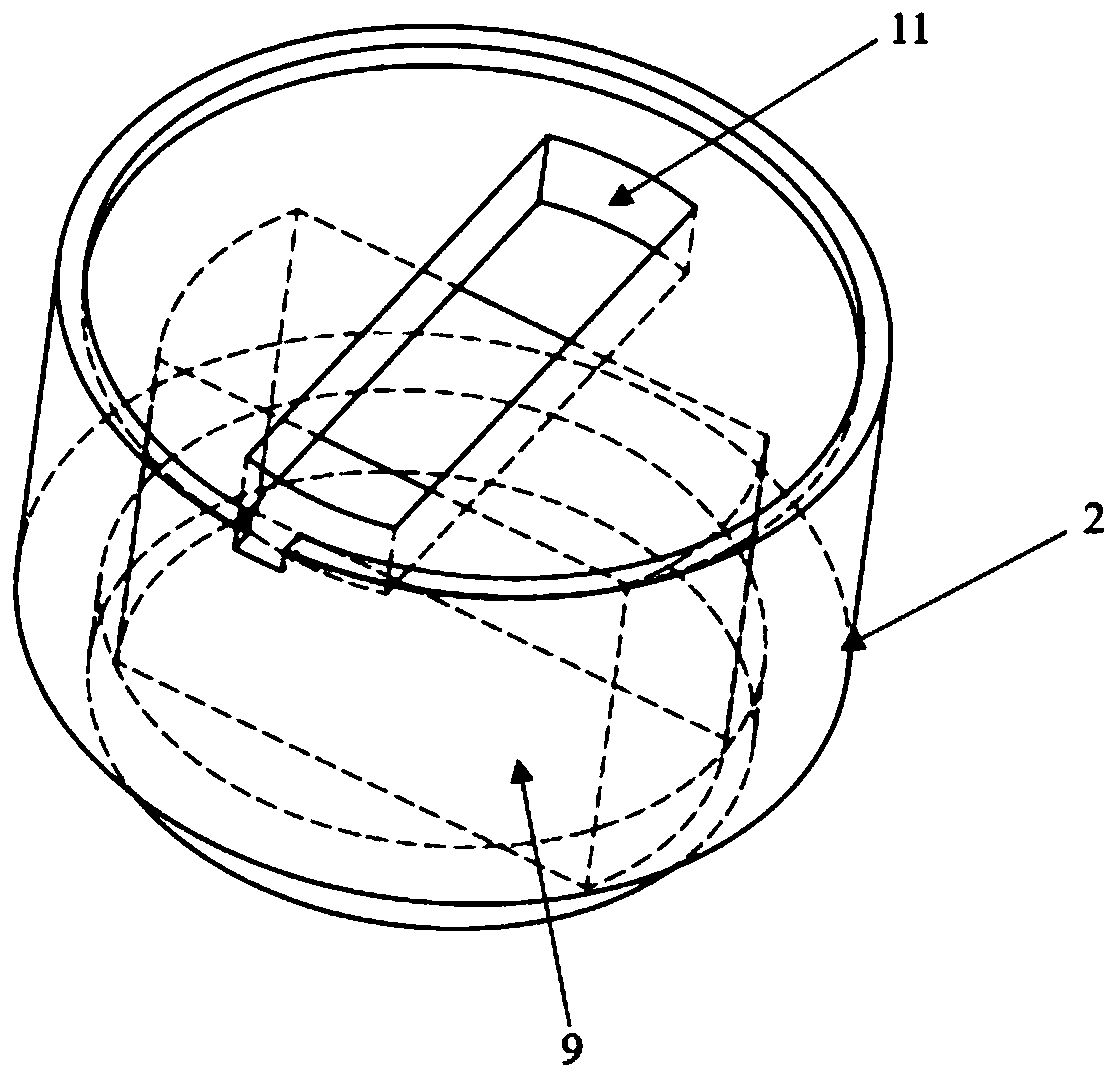

[0032] Such as figure 1 As shown, the present invention proposes a cathode optical structure of a miniature micro-focus spot X-ray tube, the cathode optical structure is installed on the anode structure 12 of the X-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com