Cable laying ship deck arrangement and construction method for laying long-distance submarine cables in sandbank sections

A cable-laying vessel, long-distance technology, applied in the direction of cable-laying vessels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

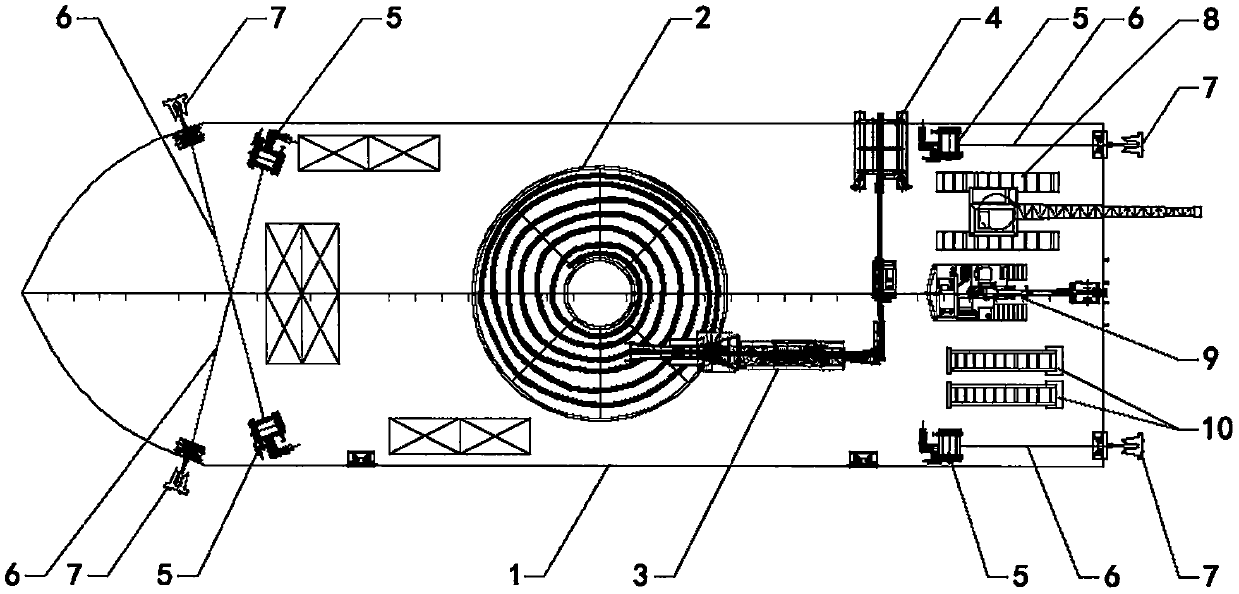

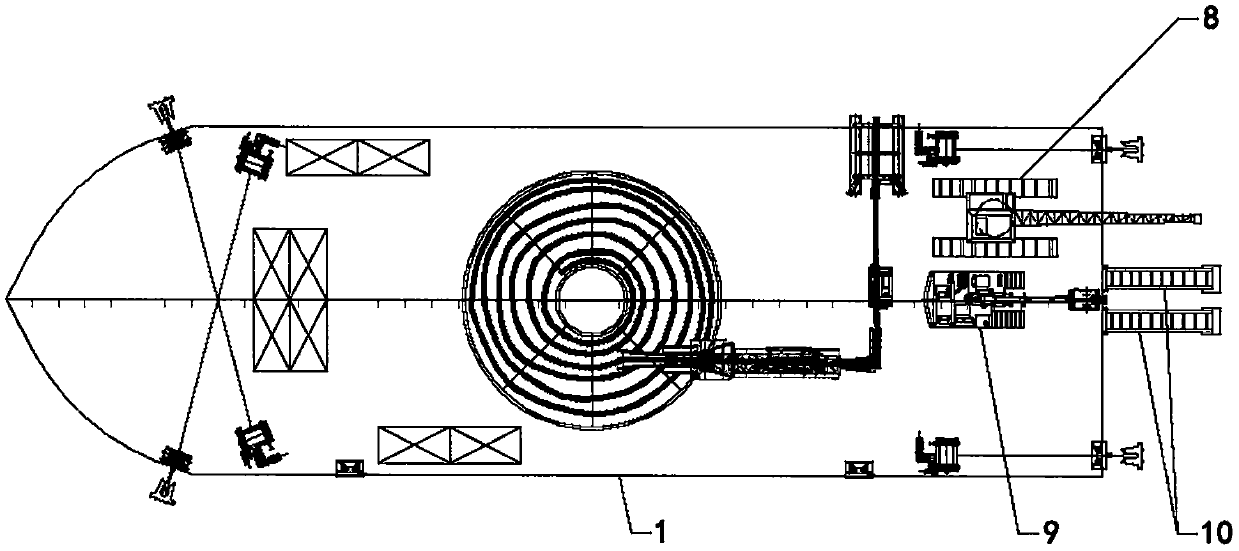

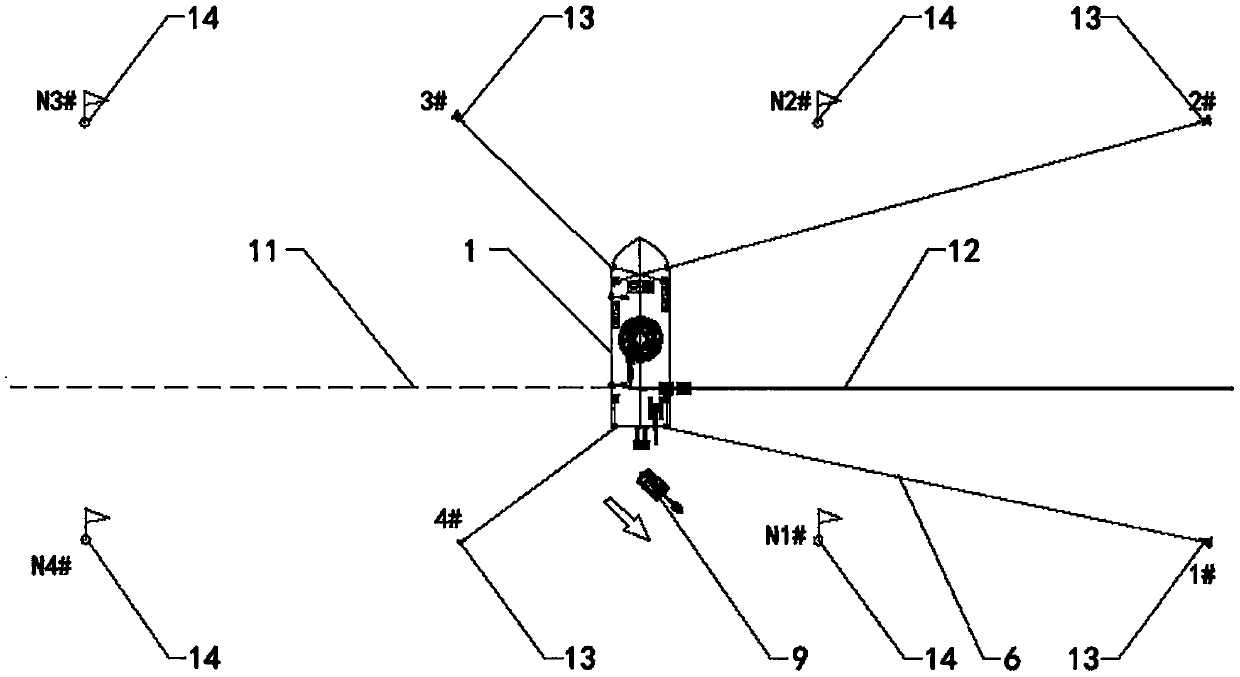

[0044] Such as figure 1 , the present invention includes a cable laying ship 1, an electric cable storage reel 2 distributed on the deck of the cable laying ship 1, a cable laying operation line 3, and a cable embedding plow 4, and a windlass 5, an anchor cable 6, and a boat are distributed on the four corners of the deck. The mooring system composed of anchor 7 is characterized in that a crane 8, an excavator 9, and a group of ladder structures 10 for the excavator 9 to lay the cable ship 1 are arranged at the rear of the deck of the cable-laying ship 1.

[0045] The cable-laying ship 1 is selected to have a smaller no-load draft, so that it meets the requirement that the draft after loading the cable 12 is smaller than the water depth during the high tide period of the sandbar section; the structural strength of the cable-laying ship 1 meets the requirements of the beaching working condition.

[0046] The lifting capacity and arm length of the crane 8 meet the requirements f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com