A fully automatic small bottle coding machine

A bottle coding machine, fully automatic technology, applied in the field of bottle coding machines, can solve the problems of increased production costs, loose or tilted bottles, low efficiency, etc., to improve efficiency and accuracy, reduce labor intensity, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that all directional indications (such as left, right, front, back...) in the embodiments of the present invention are only used to explain the relative positional relationship between the components in a certain posture (as shown in the accompanying drawings), If the specific posture changes, the directional indication also changes accordingly.

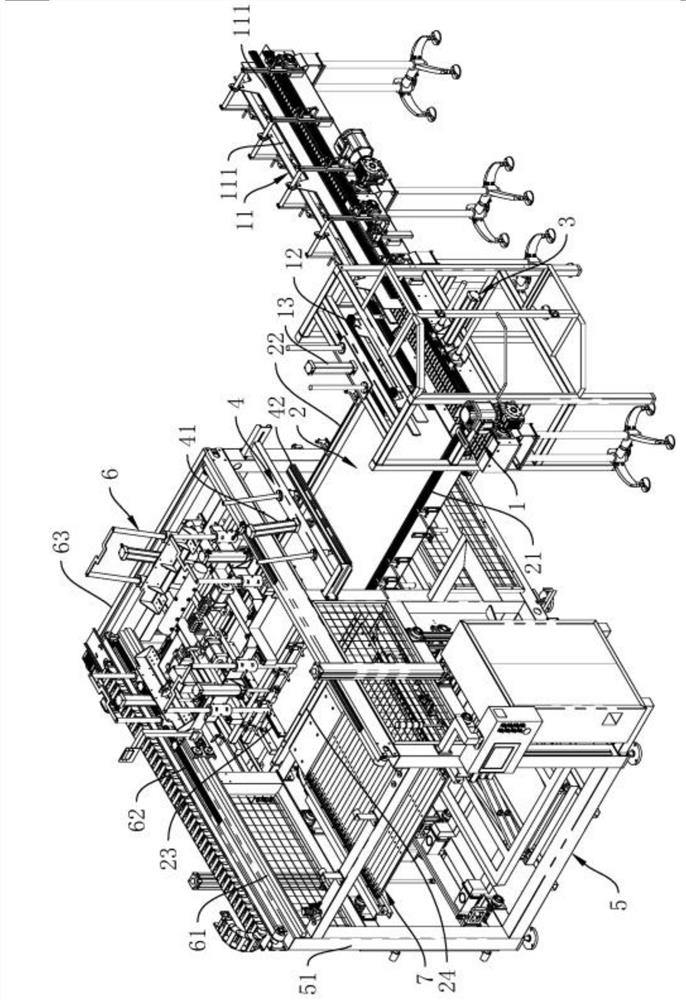

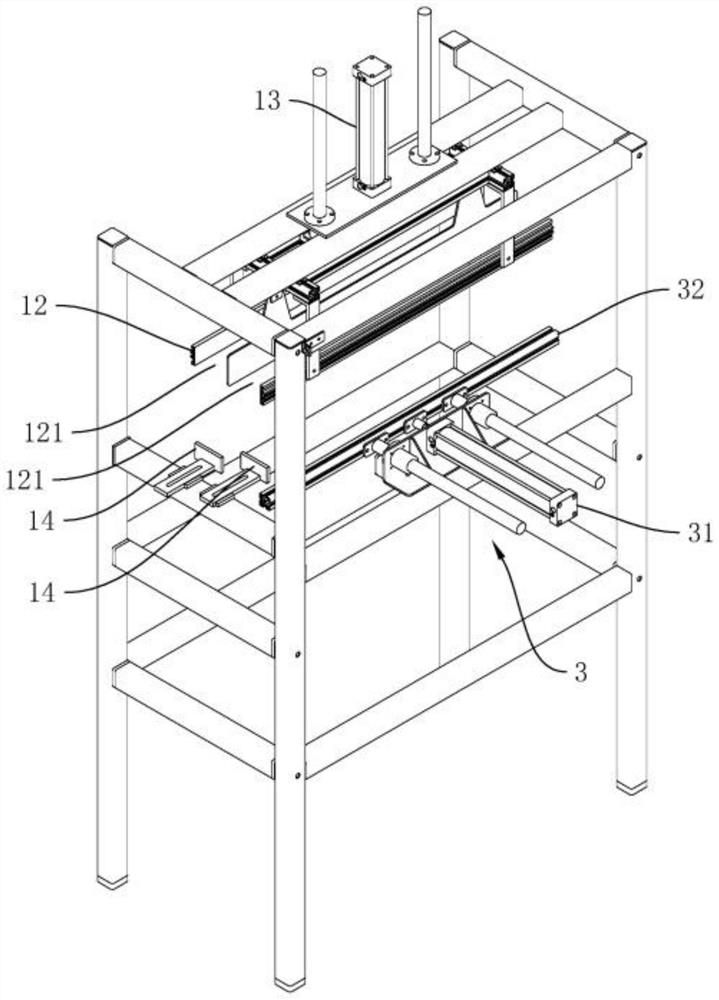

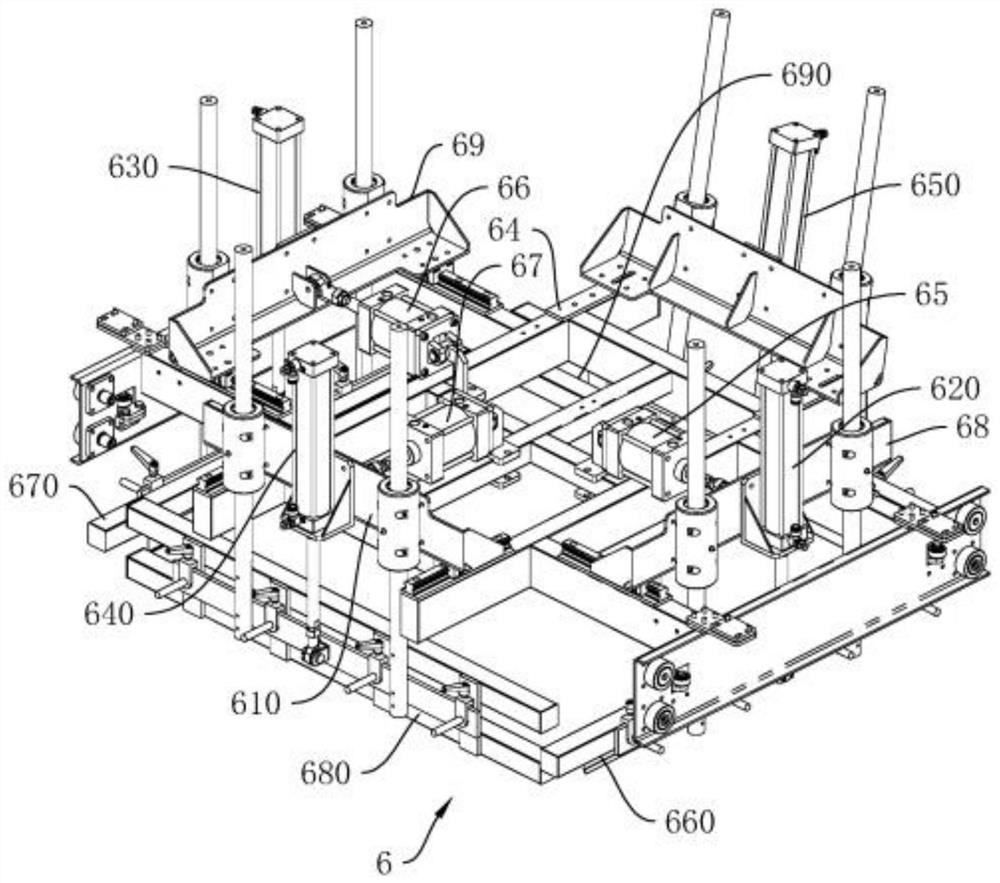

[0022] Such as figure 1 As shown, a fully automatic small bottle coding machine according to the present invention includes a first conveyor belt 1, a second conveyor belt 2, a pushing device 3, a limit device 4, a lifting and receiving device 5, and a holding device 6 , among them, such as figure 1 As shown, the input end of the second conveyor belt 2 is arranged on the side of the first conveyor belt 1; figure 1 and figure 2 As shown, the pushing device 3 includes a first cylinder 31 and a pushing member 32. The first cylinder 31 is horizontally arranged on the side of the first conveyor belt 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com