Wet-type dust falling fan impeller

A dust-wind, wet-type technology, applied in the field of wet-type dust suppression fan impeller, can solve the problems of noise pollution of surrounding workers, mechanical life, difficult to guarantee dynamic balance and installation and positioning, difficult to capture large particle dust, etc. Light, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention or the invention will be further explained by specific examples below.

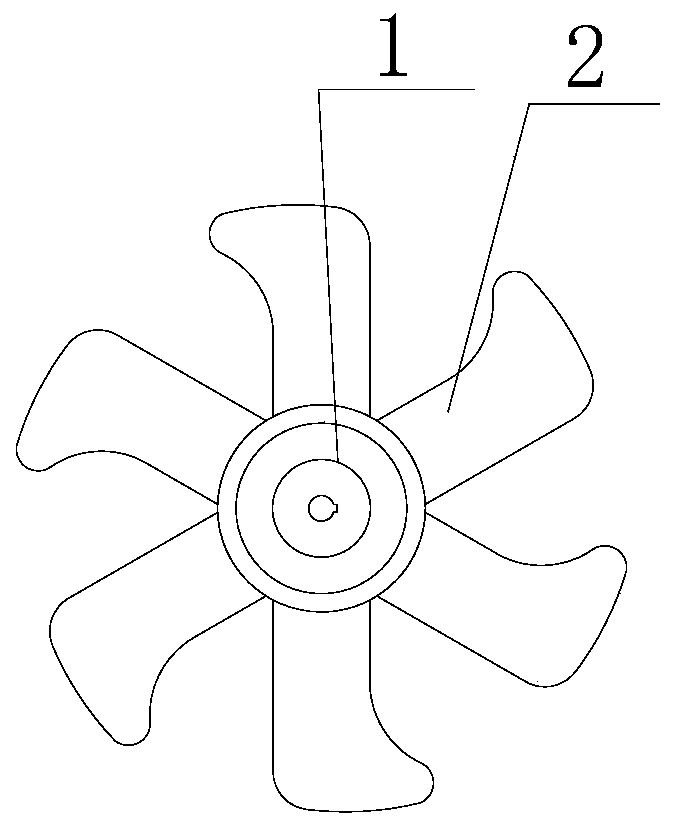

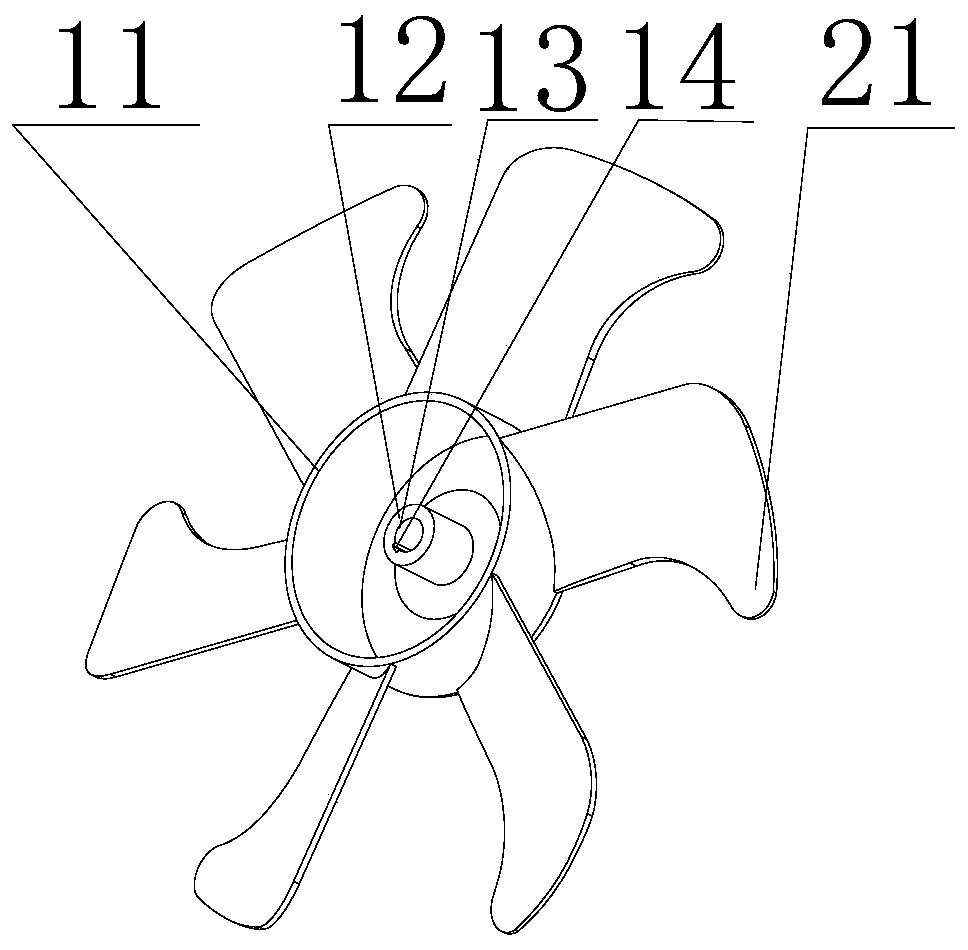

[0017] Such as figure 1 As shown, a wet-type dust suppression fan impeller, including a hub, is characterized in that: blades are evenly distributed around the outer cylindrical surface of the hub, the hub and the blades are of an integrated structure, and the material of the hub and the blades is aluminum alloy. The forming method of the hub and the blade is die casting. Such as figure 2 As shown, the hub is a thin-walled hollow structure, which reduces materials and saves costs. It includes an annular fan blade connection area and an annular shaft connection area. The shaft connection area is drilled with a central hole and milled with a keyway for easy connection with the shaft. . The blades are twisted blades with a twist angle of 5° to 10°, and the thickness is uneven. The overall characteristics are thick in the middle, thin at the edges, thick at the root, and thin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com