Complex part laser cladding interference detection and track correction method

A laser cladding and interference detection technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as interference between laser beams and other parts, damage to parts or laser equipment, etc. The effect of processing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

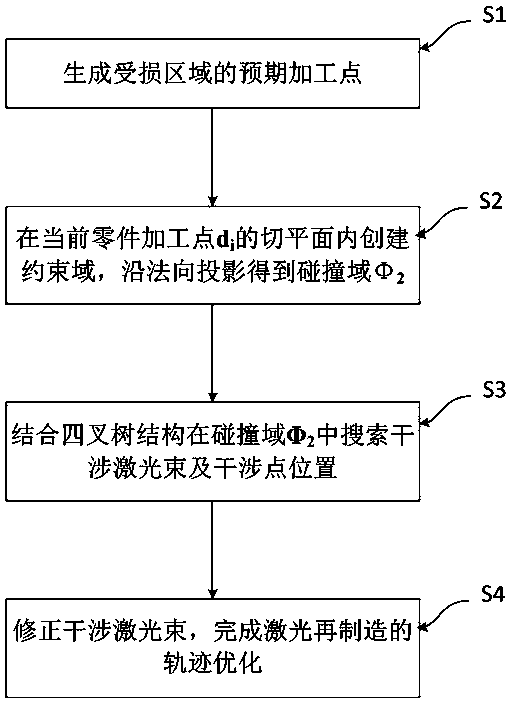

[0049] Embodiment 1: as attached figure 1 As shown, the complex parts laser cladding interference detection and trajectory correction method includes the following steps:

[0050] S1, generate the expected processing points of the damaged area, that is, generate the expected scanning path point set of the laser robot;

[0051] S2, at the current part processing point d i Create a constraint domain in the tangent plane of , and project along the normal direction to get the collision domain Φ 2 ;

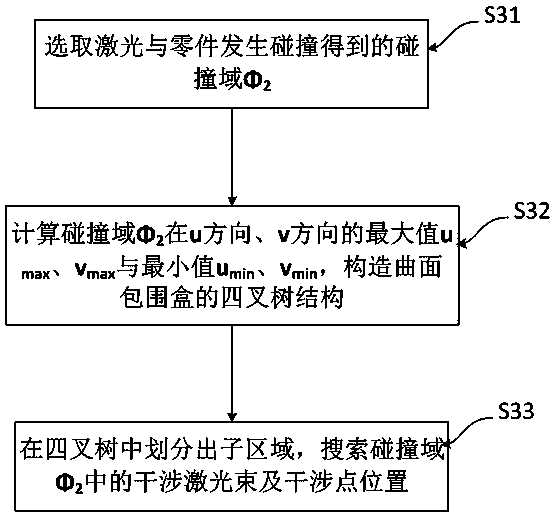

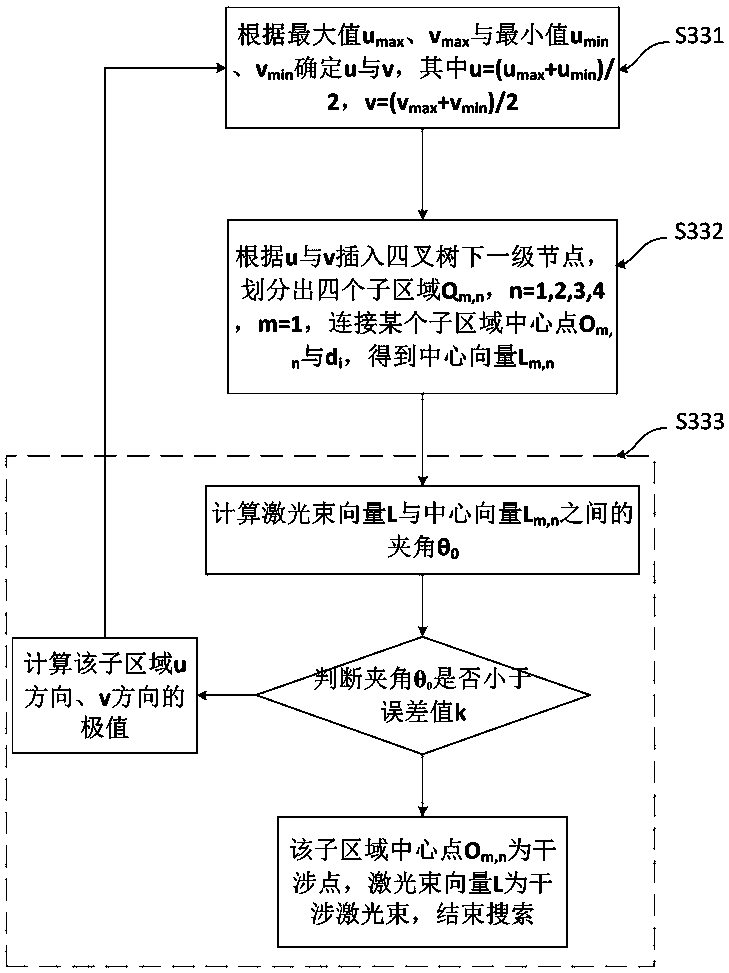

[0052] S3, combining the quadtree structure in the collision domain Φ 2 Quickly search for interfering laser beams and interfering point positions;

[0053] S4, modifying the interfering laser beam to complete the trajectory optimization of laser remanufacturing.

[0054] The invention creates a constraint domain in the tangent plane of the current part processing point, projects along the normal direction to obtain the collision domain, and combines the quadtree structure to quick...

Embodiment 2

[0081] Embodiment 2: as attached figure 1 , 11 , 12, taking the repair of the high-pressure steam valve in the boiler pipeline of a petrochemical plant as an example, the damaged area is the curved surface at the bottom of the part, as shown in the attached Figure 11 ; Establish a three-dimensional model of the damaged part and use the above method for laser beam interference detection. It is observed that there is laser interference in the boundary area of the outlet at the top of the valve, and it is corrected immediately to obtain an effective laser beam. Carry out the actual processing and comparison of laser cladding, Figure 12 a is the morphology of the damaged area, Figure 12 b is the coating morphology after cladding, it can be found that the surface of the cladding layer is smooth without obvious cracks, and the effect is good, thus proving that the present invention has high practicability and reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com