Electronic tag for passive tire pressure detection and detection method

An electronic label and detection method technology, which is applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of complex structure, increased manufacturing cost, relatively high requirements for design and micro-fabrication process, and achieves small and compact structure. Detecting effects with simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

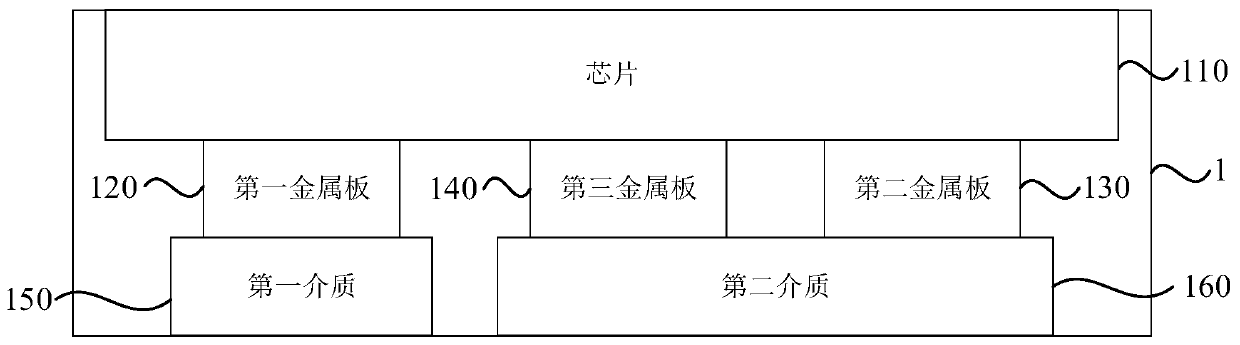

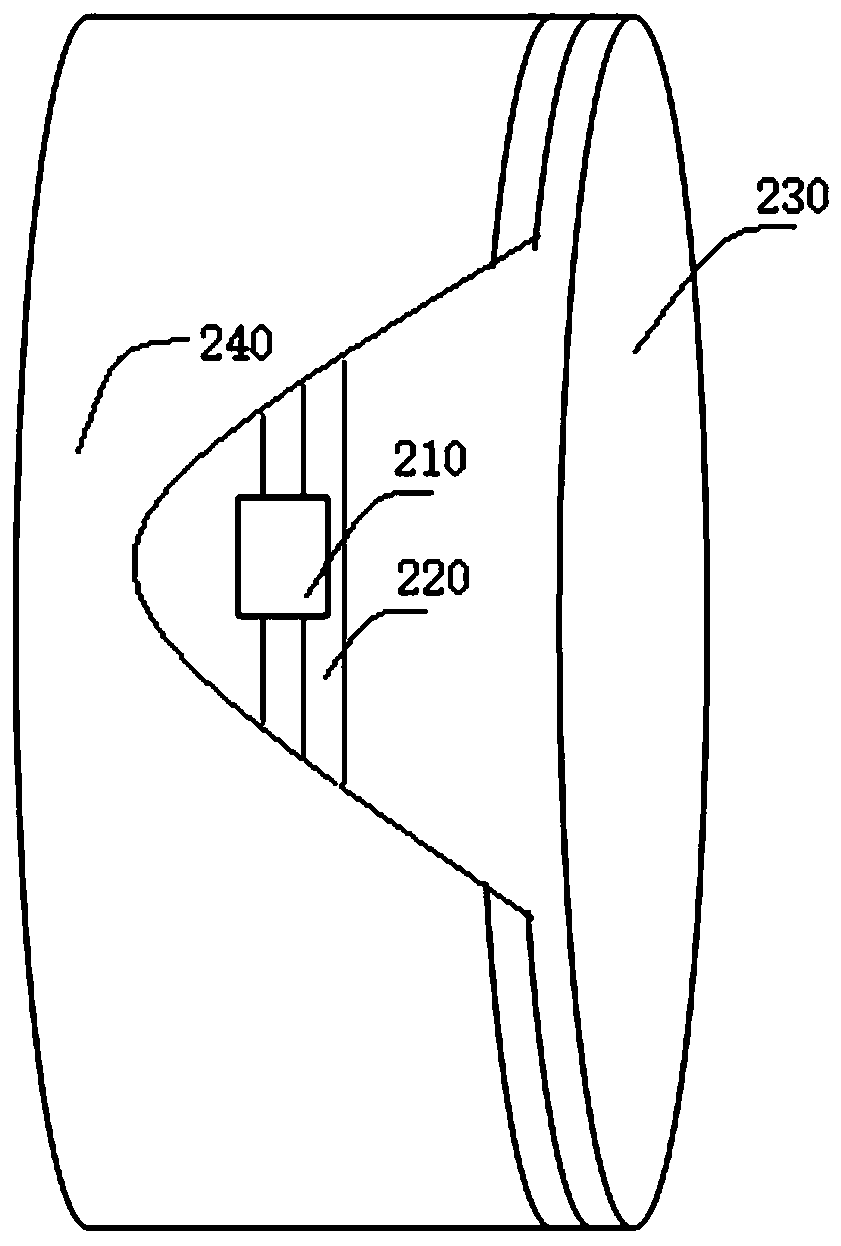

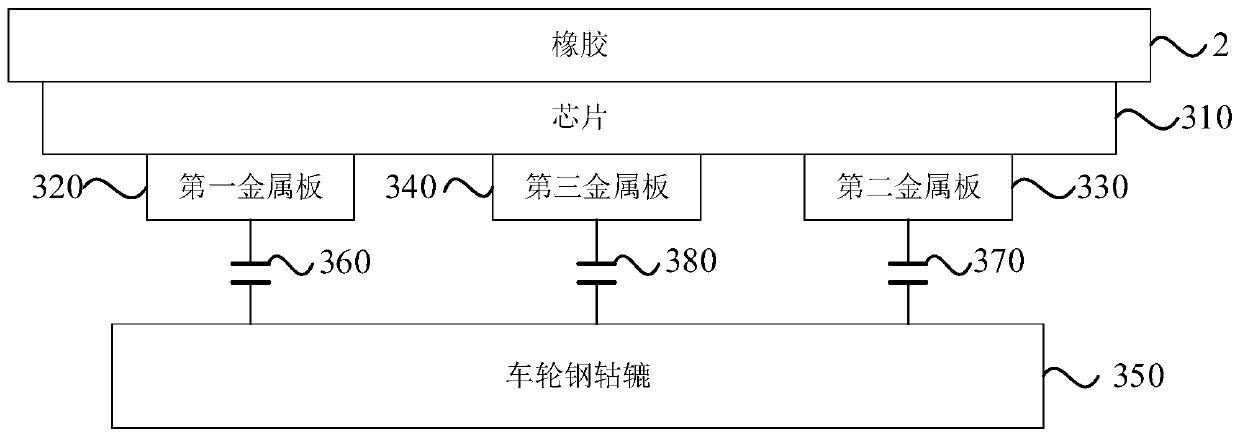

[0023] figure 1 The structural diagram of the electronic tag for passive tire pressure detection provided by Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the electronic label for passive tire pressure detection in Embodiment 1 of the present invention attached to the steel wheel of the tire wheel, image 3 It is a schematic diagram of capacitance formed by each metal plate of the electronic tag for passive tire pressure detection in Embodiment 1 of the present invention. refer to figure 1 , the electronic tag includes a chip 110, a first metal plate 120, a second metal plate 130, a third metal plate 140, a first medium 150 and a second medium 160;

[0024] Wherein, the first metal plate 120 is electrically connected to the first solder joint of the chip 110, the second metal plate 130 is electrically connected to the second solder joint of the chip 110, and the third metal plate 140 is electrically connected to the third solder joint of the c...

Embodiment 2

[0033] On the basis of the above embodiments, this embodiment describes the structure of the antenna part of the electronic tag. Figure 4 It is a structural diagram of an electronic tag for passive tire pressure detection according to Embodiment 2 of the present invention, Figure 5 It is a schematic diagram of an electronic tag for passive tire pressure detection in Embodiment 2 of the present invention, refer to Figure 4 , the electronic tag also includes an antenna 420, the first soldering point 411 is the first antenna connecting soldering point 421, the second soldering point 412 is the second antenna connecting soldering point 422, the first soldering point 421 of the antenna 420 is connected to the first soldering point 411 is electrically connected, and the second soldering point 422 of the antenna 420 is electrically connected to the second soldering point 412 .

[0034] Wherein, the first antenna connection pad 421 is shared with the first pad 411 for connecting t...

Embodiment 3

[0038] Image 6The flow chart of the passive tire pressure detection method provided by Embodiment 3 of the present invention, this embodiment is applicable to the realization of the tire pressure detection process, and the method can be implemented by the electronic tag for passive tire pressure detection described in any embodiment of the present invention To execute, specifically include the following steps:

[0039] Step 610, detecting the first capacitance formed by the first metal plate, the second capacitance formed by the second metal plate, and the third capacitance formed by the third metal plate;

[0040] Wherein, the chip can detect the first capacitance formed by the first metal plate, the second capacitance formed by the second metal plate, and the third capacitance formed by the third metal plate.

[0041] Step 620: Determine the change of the tire pressure according to the change of the first capacitor, the second capacitor and the third capacitor.

[0042] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com