Bio-polyurethane resin, bio-polyurethane resin solution and printing ink

A technology of polyurethane resin and bio-polyester, applied in the field of bio-polyurethane resin, can solve the problems of insufficient biomass degree and insufficient printing adaptability and functionality, and achieve excellent practical performance, excellent adhesion performance, and excellent dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

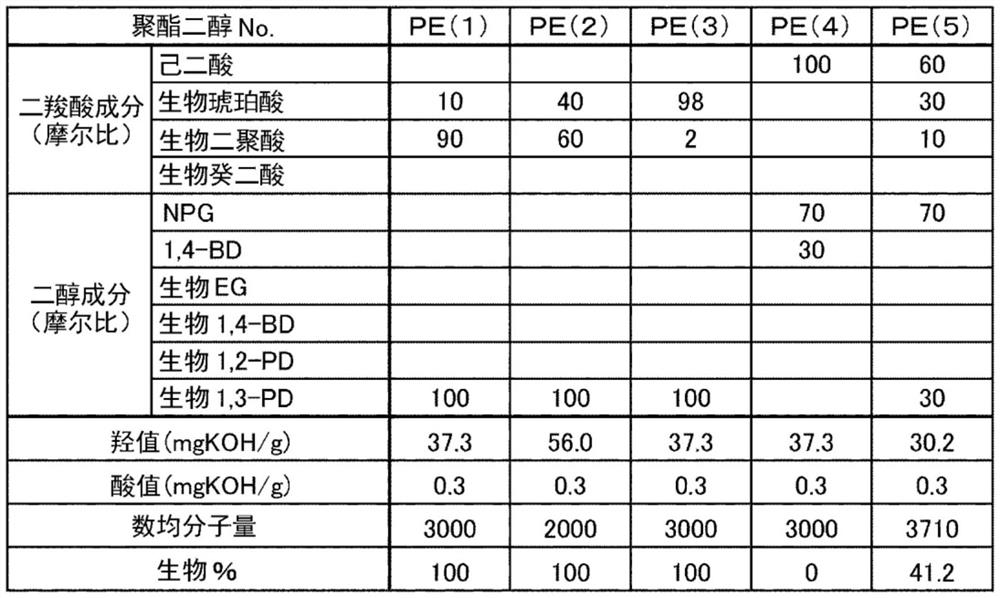

[0097] First, polyester polyol was prepared as follows. As a polyfunctional carboxylic acid component (hereinafter referred to as a dicarboxylic acid component), dimer acid containing plant-derived components (dimer purity: 98%) / succinic acid containing plant-derived components = 90 / 10 (molar ratio) was used , as a polyfunctional alcohol component (hereinafter referred to as a diol component), 1,3-propanediol containing a plant-derived component was used. And, by using these components in appropriate amounts for the target molecular weight and polymerizing, the hydroxyl value shown in Table 1-1 was 37.3 mgKOH / g, the acid value was 0.3 mgKOH / g, the number average molecular weight was 3000, and it contained 100% plant origin. Composition of polyester diol PE(1).

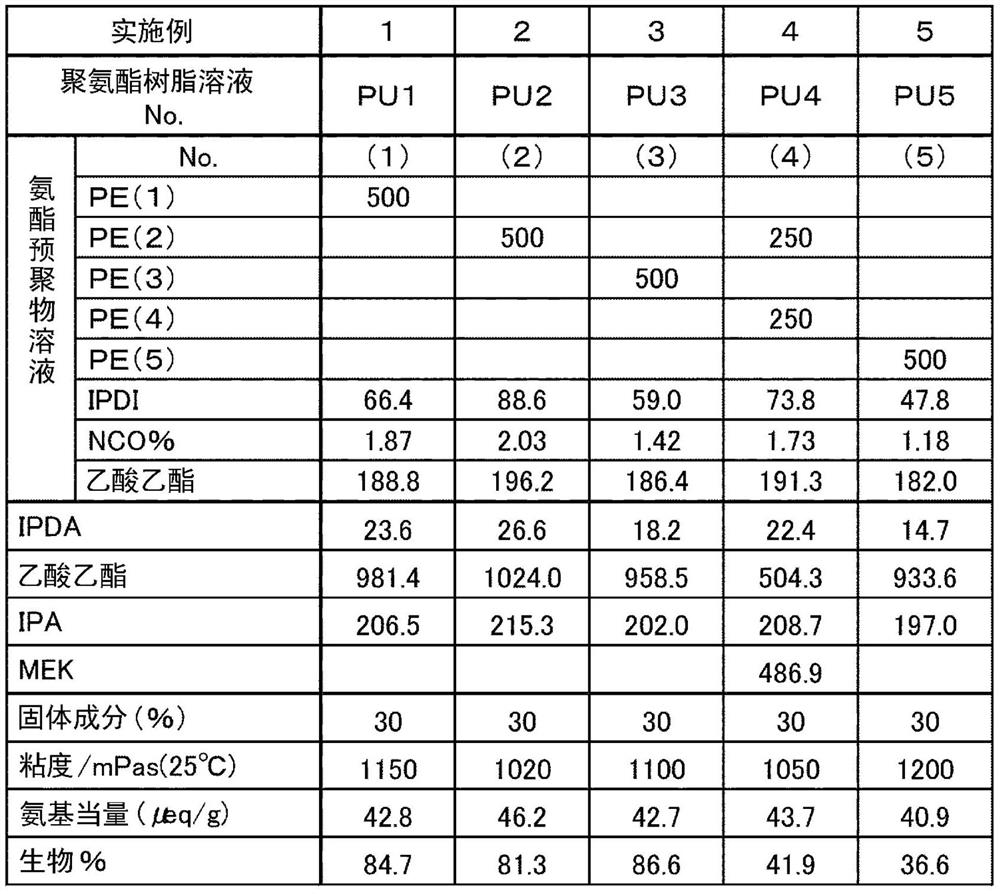

[0098] Next, 500 parts of polyester diol PE (1) obtained above and 66.4 parts of isophorone diisocyanate (hereinafter abbreviated as IPDI) as an organic diisocyanate were put into the reaction vessel, and reacted at 1...

Embodiment 2

[0101] A polyurethane resin solution was prepared basically in the same manner as in Example 1. As the dicarboxylic acid component, dimer acid containing plant-derived components (dimer purity: 98%) / succinic acid containing plant-derived components = 60 / 40 (molar ratio), and as the diol component, used Ingredient 1,3-propanediol. Then, these components were used in appropriate amounts and polymerized to obtain a polymer having a hydroxyl value of 56.0 mgKOH / g, an acid value of 0.3 mgKOH / g, a number average molecular weight of 2000, and 100% of plant-derived components, as shown in Table 1-1. Ester diol PE (2).

[0102] Next, 500 parts of the polyester diol PE (2) obtained above and 88.6 parts of IPDI were put into the reaction container, and reacted at 100° C. for 5 hours under a nitrogen stream, and the NCO group content was obtained as shown in Table 2-1. 2.03% urethane prepolymer. The obtained urethane prepolymer was dissolved in 196.2 parts of ethyl acetate to prepare a...

Embodiment 3

[0105] A polyurethane resin solution was prepared basically in the same manner as in Example 1. As a dicarboxylic acid component, dimer acid (dimer purity: 98%) containing plant-derived components / succinic acid containing plant-derived components = 2 / 98 (molar ratio) was used, and as a diol component, a plant-derived component was used Ingredient 1,3-propanediol. Then, these components were used in appropriate amounts and polymerized to obtain a polymer having a hydroxyl value of 37.3 mgKOH / g, an acid value of 0.3 mgKOH / g, a number average molecular weight of 3000, and 100% of plant-derived components shown in Table 1-1. Ester diol PE (3).

[0106] Next, 500 parts of the polyester diol PE (3) and 59.0 parts of IPDI obtained above were put into the reaction container, and reacted at 100° C. for 5 hours under a nitrogen stream, and the NCO group content was obtained as shown in Table 2-1. 1.42% urethane prepolymer. The obtained urethane prepolymer was dissolved in 186.4 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com