A Non-Uniform Inner Angle Structural Liquid Reservoir

A non-uniform and structured technology, applied in the field of spacecraft thermal control, can solve the problems that the capillary pore size cannot meet the requirements of continuous fluid supply, cannot meet the requirements of transport fluid velocity and flow rate, and the arrangement of porous media capillary structure is not unified. , to achieve the effect of enhancing capillary driving force, good encapsulation, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed by the present invention will be further described in detail below in conjunction with the accompanying drawings.

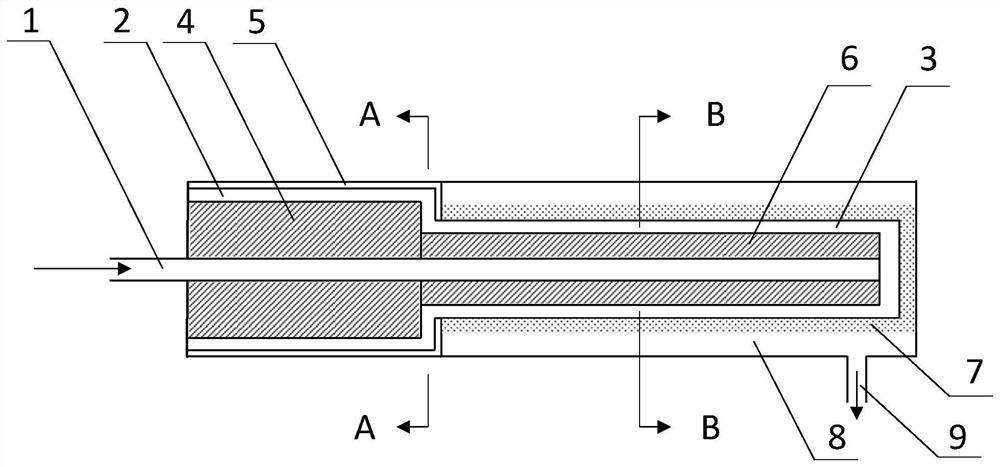

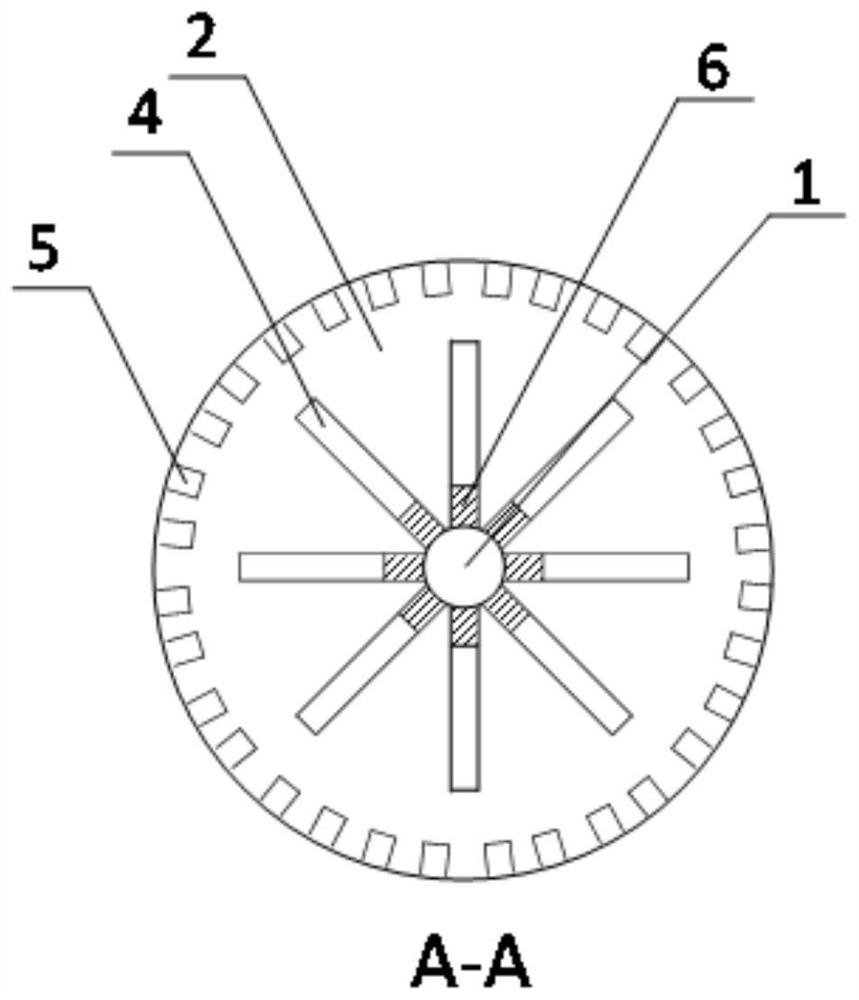

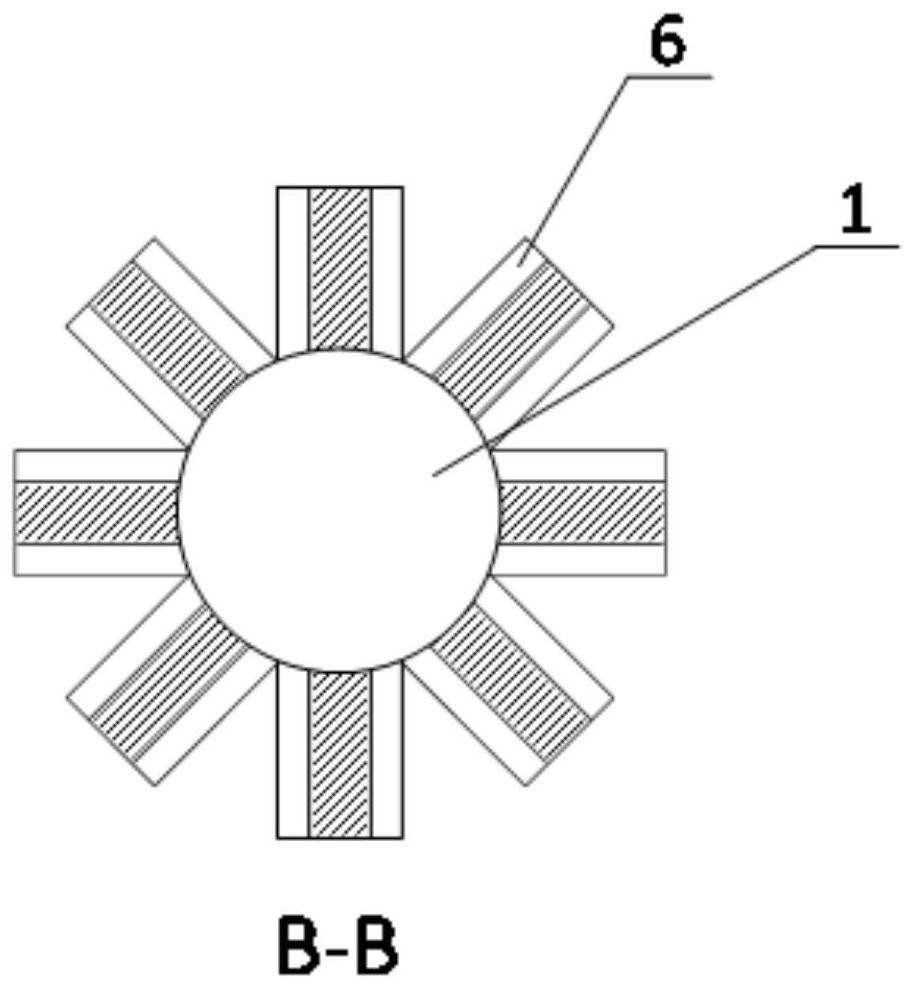

[0042] Such as Figure 1~3 , in this embodiment, the non-uniform internal angle structure liquid reservoir includes: liquid pipeline 1, main liquid storage chamber 2, auxiliary liquid storage chamber 3, primary internal angle structure 4, micro groove structure 5 and secondary internal angle structure 6. Among them, the main liquid storage chamber 2 and the auxiliary liquid storage chamber 3 are coaxial through chambers with unequal cross-sectional areas; the liquid pipeline 1 passes through the main liquid storage chamber 2 and reaches the farthest end of the auxiliary liquid storage chamber 3; The inner angle structure 4 is arranged in the main liquid storage chamber 2, and the secondary inner angle structure 6 is arranged in the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com