Device for packing and counting cylindrical bar materials

A cylindrical bar and cylindrical pin technology, which is applied to the field of online cutting cylindrical bar material packaging, can solve the problems of low work efficiency, difficult packaging, and error-prone quantity counting, and achieves the effects of high work efficiency, simple operation and high use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

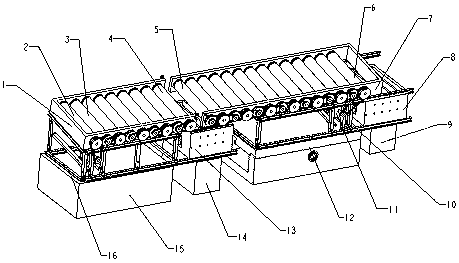

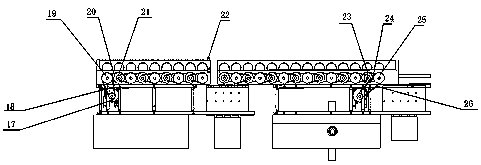

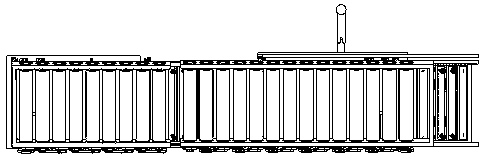

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the support frame I (1) is fixed on the bracket I (16) through a detachable connection, the bracket I (16) is fixed on the base (15) through a detachable connection, and the metal rod I (2) is connected to the The support frame I (1), the metal rod II (3) are connected to the support frame I (1) through bearings, the motor I (17) is connected with the V-belt I (18), and the V-belt I ( 18) It is connected with the pulley I (19), the pulley I (19) is connected with the metal stick I (2) through a key connection, and the pulley II (21) is connected with the metal stick II (3) through a key connection. ), the pulley I (19) is connected to the V-belt II (20), the V-belt II (20) is connected to the pulley II (21), and the arrangement of other metal sticks is as above, A small cylinder is welded on the right side of the support frame I (1), and a small cylinder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com