Hollow fiber braided tube filter membrane for reducing sewage as well as preparation method and application of hollow fiber braided tube filter membrane

A fiber braided tube, hollow technology, used in chemical instruments and methods, permeation/dialysis water/sewage treatment, membranes, etc. Effects of salt/dirt performance, large evaporation specific surface area, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

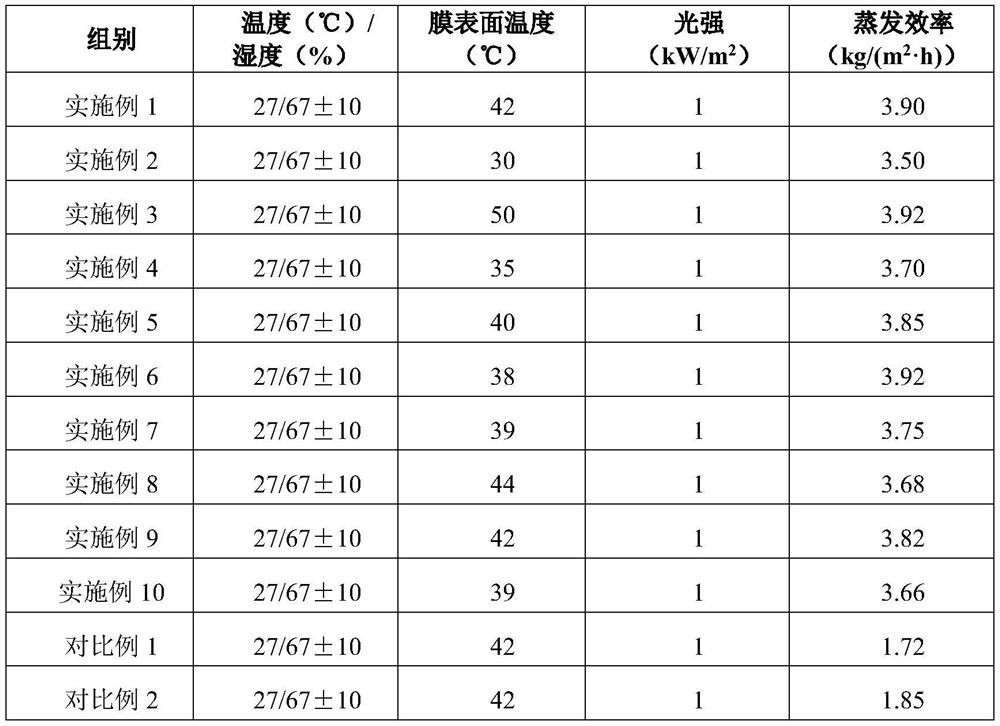

Examples

Embodiment 1

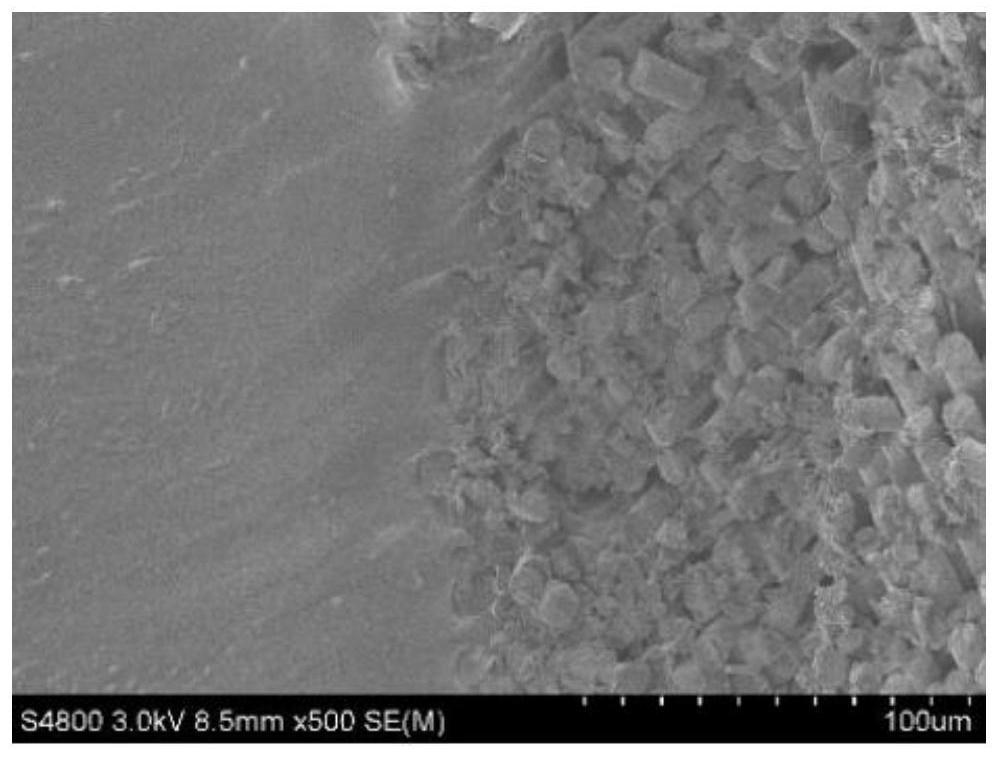

[0043] (1) 10wt% polyvinylidene fluoride, 10wt% tetraethyl orthosilicate, 0.5w% hydrochloric acid and 10.0wt% carbon black were dissolved in N,N-dimethylacetamide at room temperature, and treated by ultrasonic stirring 24h, to obtain a uniform casting solution containing carbon black photothermal material;

[0044] (2) dissolving 10.0 wt% polydimethylsiloxane in n-hexane, stirring mechanically until the solution is clear and transparent to obtain a hydrophobic polydimethylsiloxane polymer dispersion;

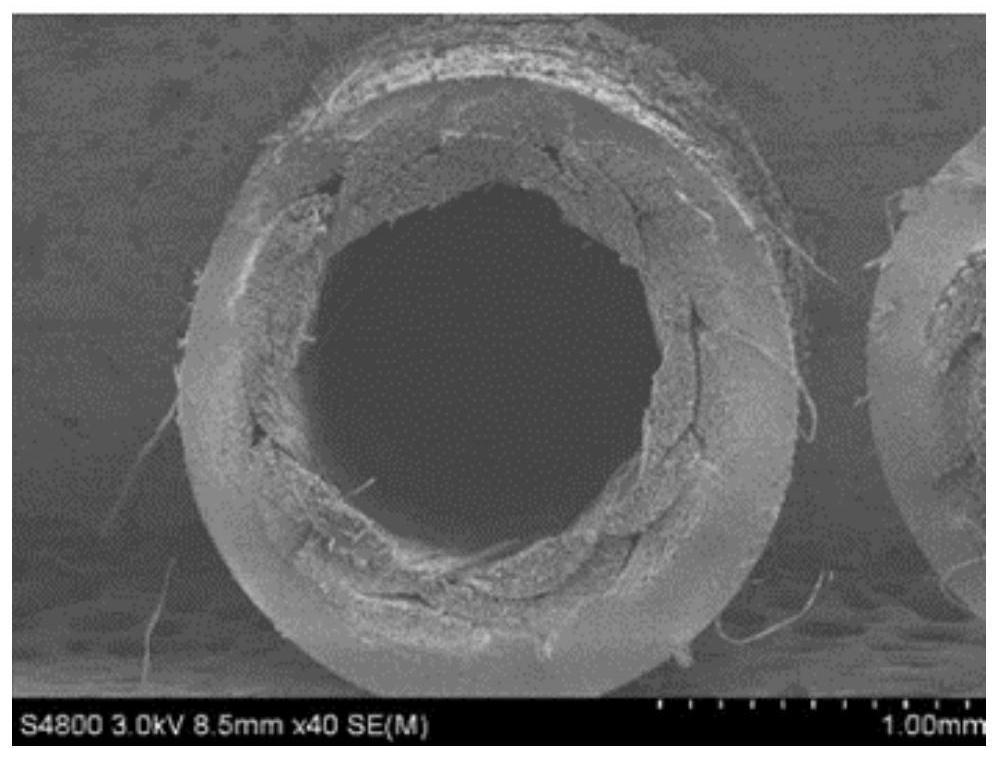

[0045] (3) Through the surface traction dip-coating modification technology, the light-to-heat conversion functional material carbon black and the hydrophobic polymer polydimethylsiloxane are sequentially fixed on the outer surface of the polyethylene terephthalate hollow fiber braided tube; Fix at a high temperature of 80°C, wash with water and dry to obtain a hollow fiber braided tube filter membrane for sewage reduction.

[0046] Wherein, step (1) and step (2) are not limite...

Embodiment 2

[0048] (1) 5wt% polysulfone, 2wt% tetrabutyl titanate, 0.2wt% hydrochloric acid and 0.2wt% graphene were dissolved in N-methylpyrrolidone at room temperature, and treated with ultrasonic stirring for 12h to obtain graphene-containing light Homogeneous casting solution for hot materials;

[0049] (2) Dissolving 0.2wt% triethoxyfluorosilane in n-heptane, stirring mechanically until the solution is clear and transparent, to obtain a hydrophobic triethoxyfluorosilane polymer dispersion;

[0050] (3) Through the surface traction dip coating modification technology, the light-to-heat conversion functional material graphene and the hydrophobic polymer triethoxyfluorosilane are sequentially fixed on the outer surface of the polytetrafluoroethylene hollow fiber braided tube; Washing with water and drying to obtain a hollow fiber braided tube filter membrane for waste water reduction.

[0051] Wherein, step (1) and step (2) are not limited in sequence.

Embodiment 3

[0053] (1) 20wt% polyethersulfone, 17wt% tetraethyl orthosilicate, 1.0wt% hydrochloric acid and 20wt% reduced graphene oxide were dissolved in N,N-dimethylformamide at room temperature, and treated by ultrasonic stirring 48h, obtain the homogeneous casting liquid that contains graphene photothermal material;

[0054] (2) 20 wt% tridecafluorooctyltrimethoxysilane was dissolved in n-heptane, and mechanically stirred until the solution was clear and transparent to obtain a hydrophobic tridecafluorooctyltrimethoxysilane polymer dispersion;

[0055] (3) Through the surface traction dip coating modification technology, the photothermal conversion functional material reduced graphene oxide and the hydrophobic polymer tridecafluorooctyltrimethoxysilane are sequentially fixed on the outer surface of the nylon hollow fiber braided tube; Fixing, washing with water and drying to obtain a hollow fiber braided tube filter membrane for waste water reduction.

[0056] Wherein, step (1) and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com