Bush turning tool for overhauling power generator bearing bush in large thermal power plant

A technology for thermal power plants and generators, applied in the direction of load suspension components, transportation and packaging, etc., can solve problems such as easy damage to the main shaft or bearing bush, narrow working place, secondary damage, etc., to improve maintenance quality and safety risks Good and adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

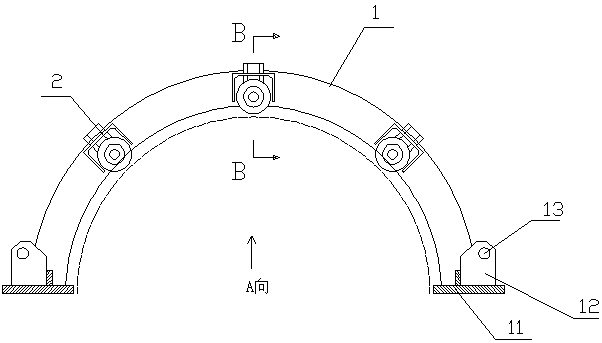

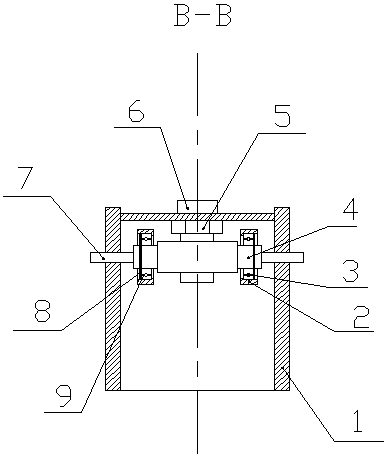

[0033] A tool for overhauling generator bearing bushes in a large-scale thermal power plant, including a semicircular frame 1, on which three sets of bearings are arranged; the bearings include rollers 2, dust-proof deep groove ball bearings 3, and roller shafts 4; The roller 2 is connected to the roller shaft 4 through a bearing 3, and the two ends of the roller shaft are fixed on the frame by set screws 7; the center of the roller shaft 4 is fixedly connected to the top of the frame by a nut 5 and a hex head bolt 6 A retaining ring 8 for the shaft is provided between the bearing and the set screw 7, and a retaining ring for the hole is provided between the roller 2 passing through the bearing 3 .

[0034] The bottom of the frame is provided with a supporting sleeve, which is used for fixing the bolts at the bottom of the frame.

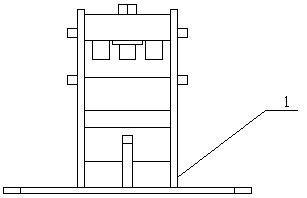

[0035] A base plate 11 is provided at the bottom of the frame, and an ear plate 12 is provided on the base plate; a hoisting hole 13 is provided on...

Embodiment 2

[0039] The use process of the brick-turning tool of embodiment 1 is:

[0040] 1. Lift the tile-turning tool firmly and smoothly to the upper half of the original generator bearing tile and place it in place. When falling down, try to make the connecting hole of the fixed bottom plate align with the corresponding screw hole on the lower half of the tile. The fixing bolts and supporting sleeves of the random packing parts (note: do not tighten them temporarily), move the fixed bottom plate a little to keep the tile-turning tool and the center of the tile basically on the same axis, and tighten the fixing bolts after the position adjustment is completed.

[0041] 2. Adjust the three pairs of rollers on the tile-turning tool so that they are tightly attached to the generator rotor, and then lightly tap with a copper rod to check the tightness. After the roller and the rotor are tightly attached, fasten the roller with a wrench, so as to lift the lower half of the tile moderately. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com