Optical glass

An optical glass, optical technology, applied in optics, optical components, instruments, etc., can solve problems such as scrapping, low moisture resistance, affecting glass quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

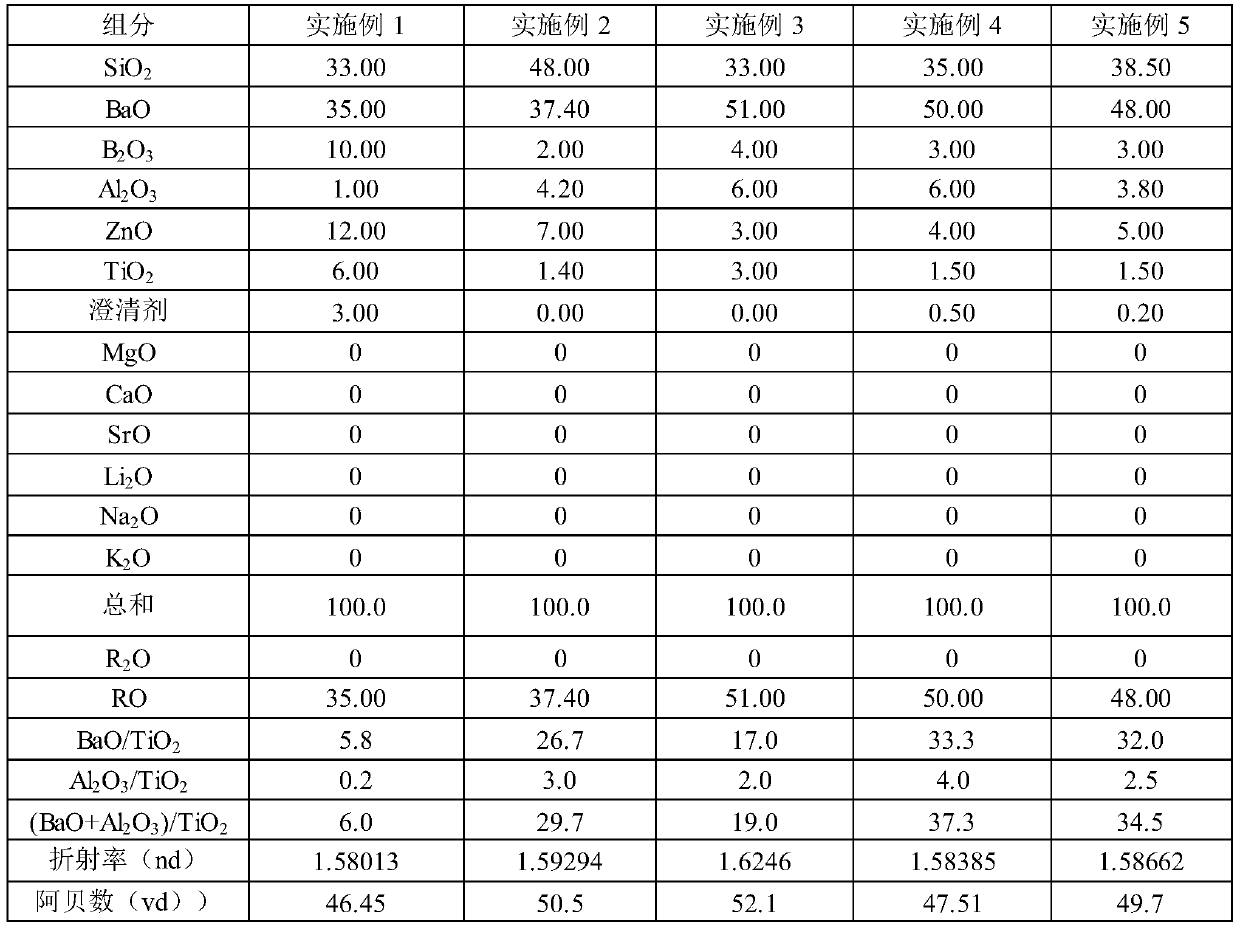

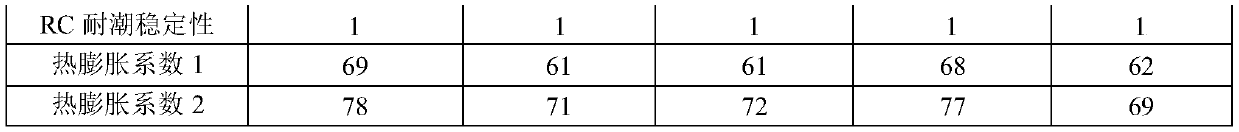

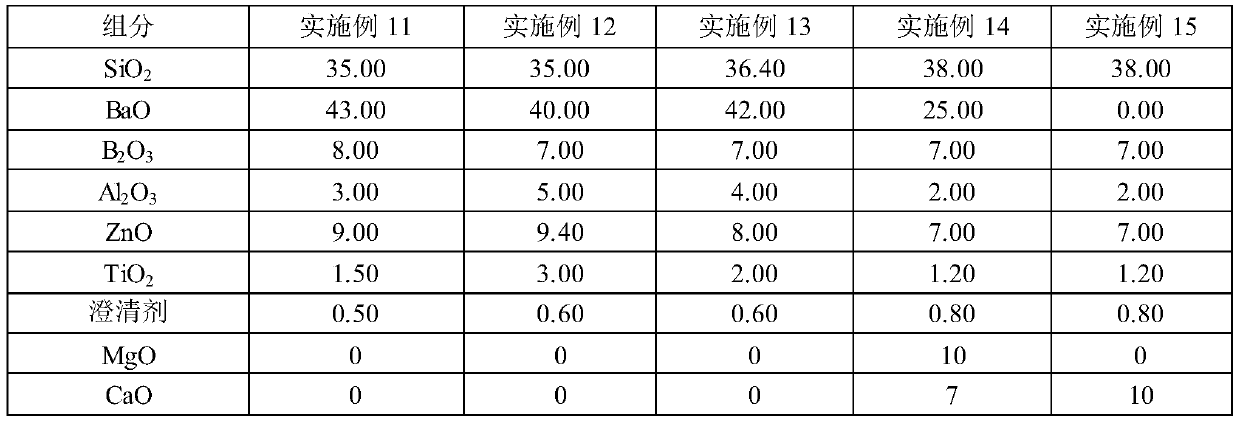

[0043] The composition range of each component of the optical glass of the present invention will be described below with reference to the examples. In this specification, unless otherwise specified, the content of each component is expressed in weight percent (wt %) relative to the total amount of glass substances converted into oxides. Here, the "composition in terms of oxides" refers to the case where oxides, composite salts, hydroxides, etc. used as raw materials for the optical glass composition of the present invention are decomposed and converted into oxides during melting , and the total amount of the oxide was taken as 100%.

[0044] Unless otherwise indicated in a specific instance, the numerical ranges set forth herein include the upper and lower values, "above" and "below" include the endpoints, all integers and fractions within the range, and are not intended to be limiting when the range is defined specific values listed. The term "and / or" herein is inclusive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com