Superposed type cable well top plate structure and construction method thereof

A cable well and roof technology, which is used in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of reducing construction efficiency, affecting the construction period, and large thickness of the roof, meeting the requirements of ensuring waterproof performance and shortening construction. The effect of construction period and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Best practice:

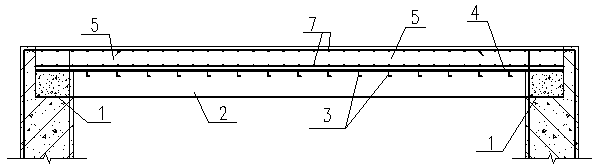

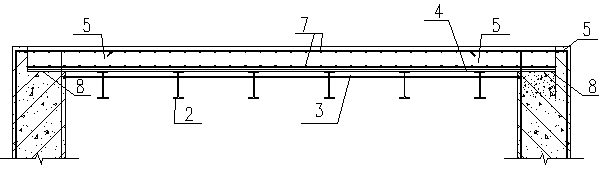

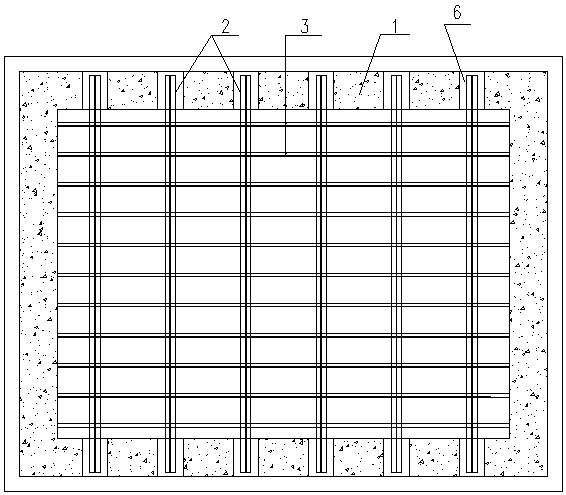

[0030] Refer to attached Figure 1-4 , a superimposed electric cable well roof structure, the top of the two side walls of the electric cable well is provided with L-shaped steps 1, including H-shaped steel main beam 2, channel steel secondary beam 3, steel plate 4 and poured concrete slab 5; H The two ends of the shaped steel main beam 2 are respectively erected on the L-shaped steps 1 on the top of the two side walls of the cableman's well, and an H-shaped steel main beam 2 is distributed on the L-shaped steps 1 every set distance; the channel steel secondary beam 3 is located at the H The lower end surface of the upper flange of the shaped steel main beam 2 is welded to two adjacent H-shaped steel main beams 2 at both ends, and a channel steel secondary beam 3 is distributed at a set distance on the H-shaped steel main beam 2; The beam 3 is covered with steel plates 4, and the steel plates 4 are distributed parallel to the H-shaped steel main beam 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com