Construction method of assembled curved surface suspended ceiling

A construction method and prefabricated technology, applied in the direction of ceiling, building material processing, building components, etc., can solve problems such as installation difficulties of curved ceilings, achieve the effect of improving construction quality, improving construction efficiency, and solving installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

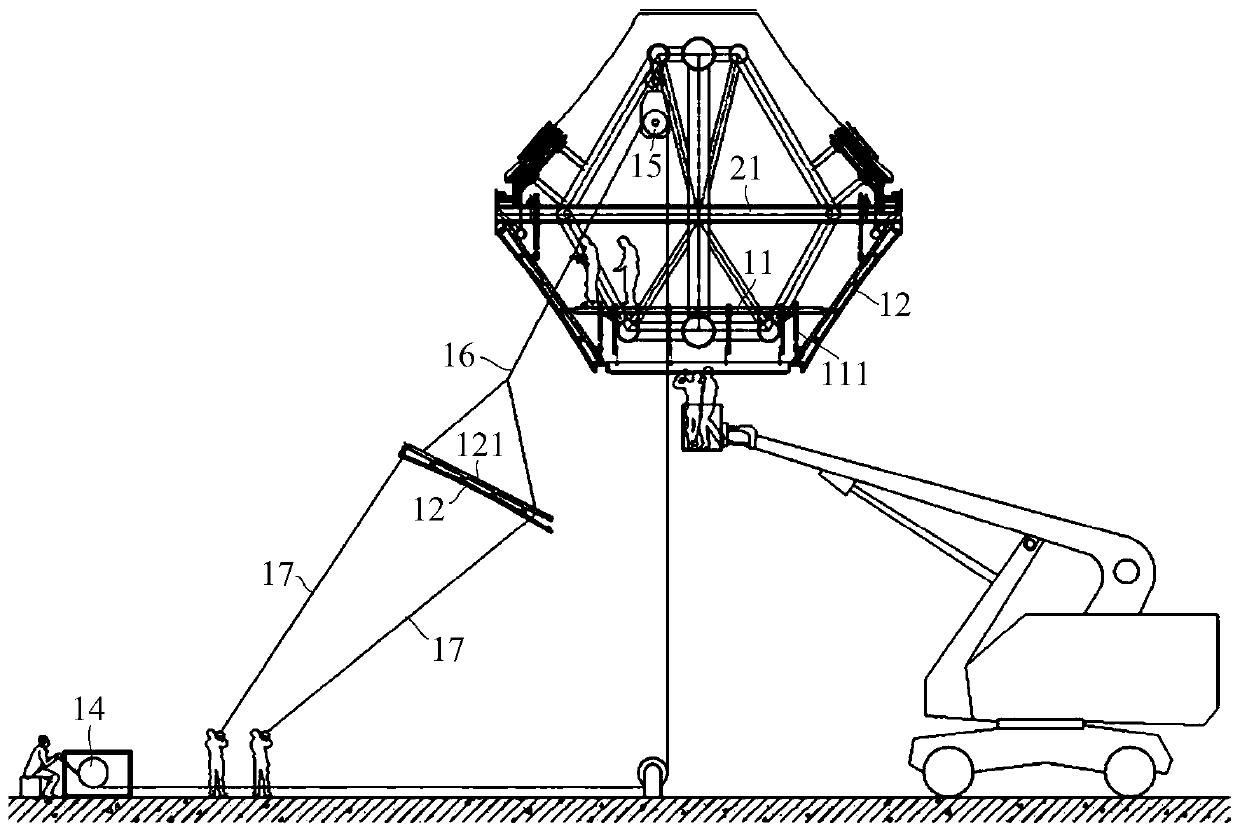

[0053] As a preferred embodiment of the present invention, when installing the connector 111, it also includes:

[0054] According to the BIM structure diagram, use a three-dimensional scanner and a total station to carry out on-site lofting of the main structure 21 to determine the installation nodes of the curved panel unit 12, and mark the corresponding position on the steel frame, and then install the connector 111 vertically on the steel frame. At the marked points on the skeleton, since the connecting piece 111 is vertically arranged, the force receiving and transmission of the connecting piece 111 can be more stable.

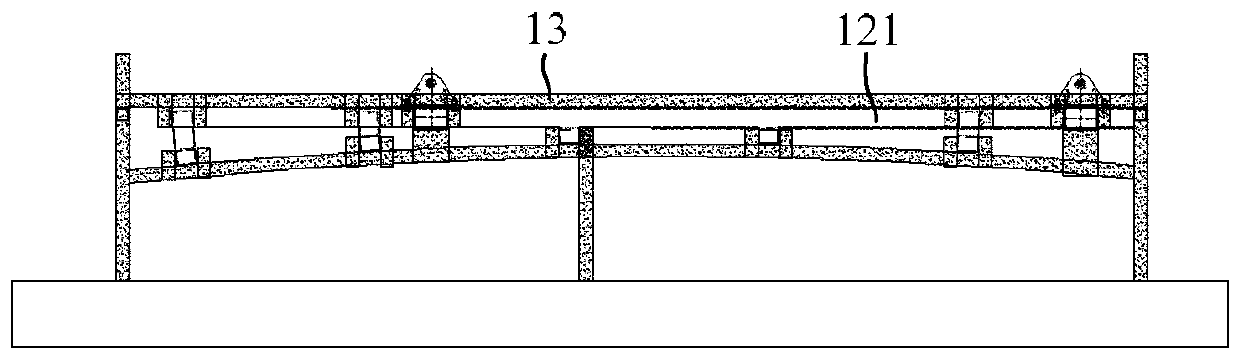

[0055] Further, combine image 3 and Figure 4 When making a panel skeleton as shown, also include:

[0056] A positioning template 13 is provided, and a positioning surface is formed on the positioning template 13;

[0057] Determine the spacing between the transverse and longitudinal beams of the panel frame 121 to be formed according to the BIM mode...

specific Embodiment approach

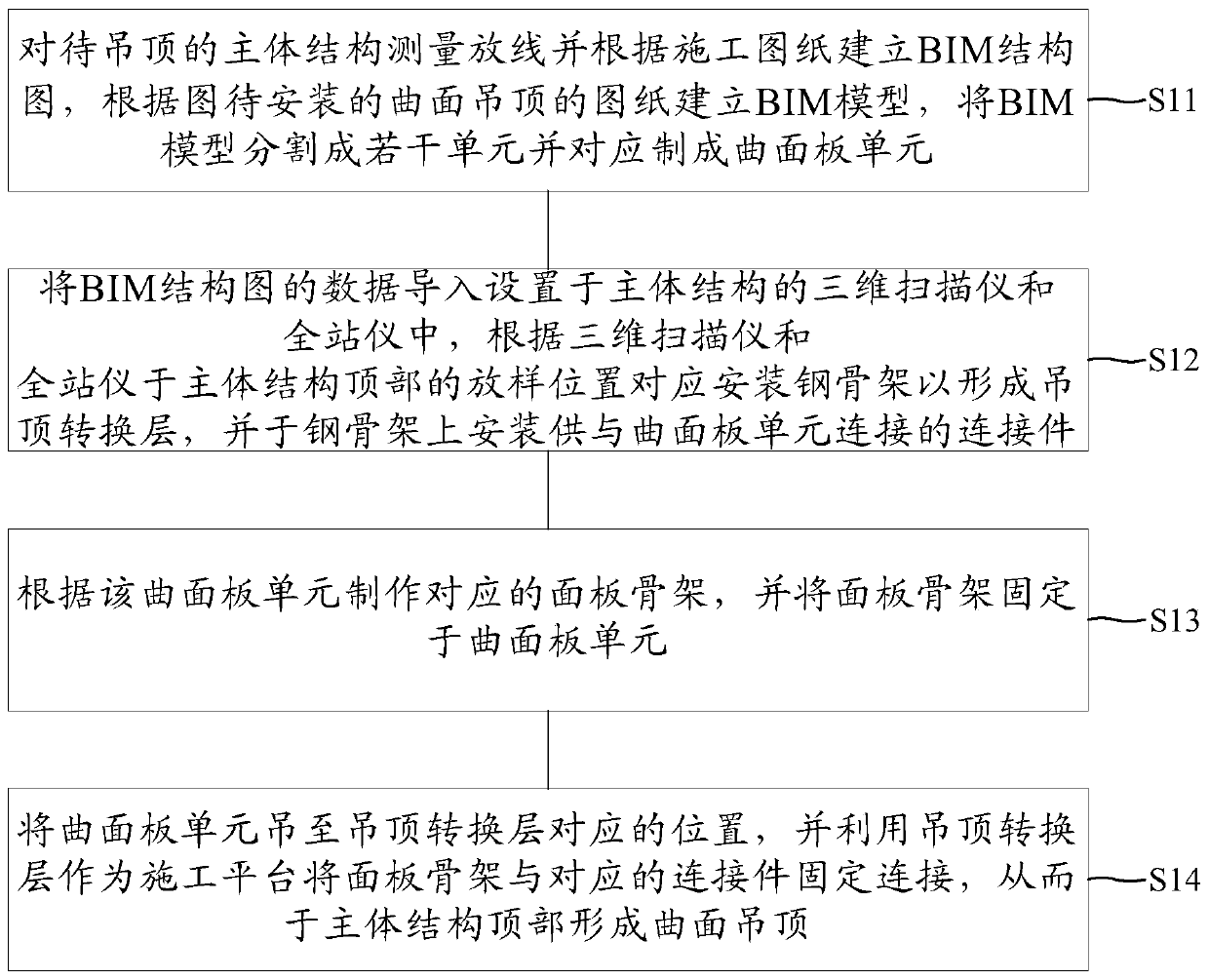

[0083] Firstly, the main structure 21 of the suspended ceiling is measured and laid out, and the corresponding BIM structure diagram is established, and the BIM model of the curved ceiling is established according to the drawings, and the BIM model is divided into several units and correspondingly processed into curved panel units 12;

[0084] According to the BIM structure diagram, a steel frame is installed on the top of the main structure 21, and diagonal braces are set between the steel frame and the main structure 21 to form a stable ceiling transition layer 11, and the main structure 21 is laid out using the BIM structure diagram to indicate Connector 111 is to be connected to the node of the curved panel unit 12, and the connector 111 is vertically installed on the position corresponding to the node on the steel skeleton, so that the end of the connector 111 away from the steel skeleton coincides with the node, and the connector 111 keeps vertical;

[0085] According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com