Centrifugal type stepless drive decelerating mechanism

A technology of infinitely variable speed and deceleration mechanism, used in clutches, mechanical equipment, one-way clutches, etc., can solve the problems of use, inability to have a wider application environment, and a fixed deceleration range, and achieve convenient use, simple structure, and fewer parts. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

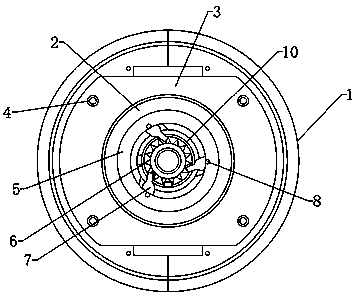

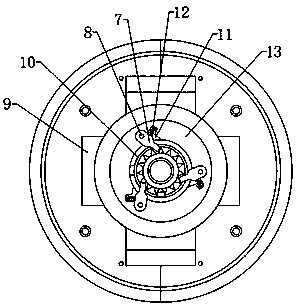

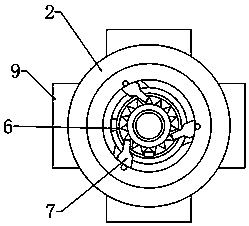

[0016] attached Figure 1-4 It is a specific embodiment of the present invention. The invention is a centrifugal infinitely variable speed reduction mechanism, which includes a reduction wheel assembly 1, a brake wheel body 2 and a one-way bearing 10. The brake wheel body 2 is provided with a plurality of limit splicing blocks 9, and the brake wheel body 2 passes through each The limit splicing block 9 and the speed reduction wheel assembly 1 are spliced by connecting the main board 3, and the speed reduction wheel assembly 1 is provided with a groove consistent with the outer contour of the limit splicing block 9, and each speed reduction wheel assembly 1 utilizes the connecting bolt 4 to connect the main board 3. Connecting and splicing into a whole, a return tension spring 15 is installed between two adjacent reduction wheel assemblies 1, a limit gear 6 is provided on the one-way bearing 10 of the brake wheel body 2, and a limit gear 6 is arranged on the brake wheel body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com