Kitchen range burner

A technology for burners and stoves, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of limited fire holes and inability to increase fire load, etc., to promote full combustion, increase usable surface area, and improve The effect of available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

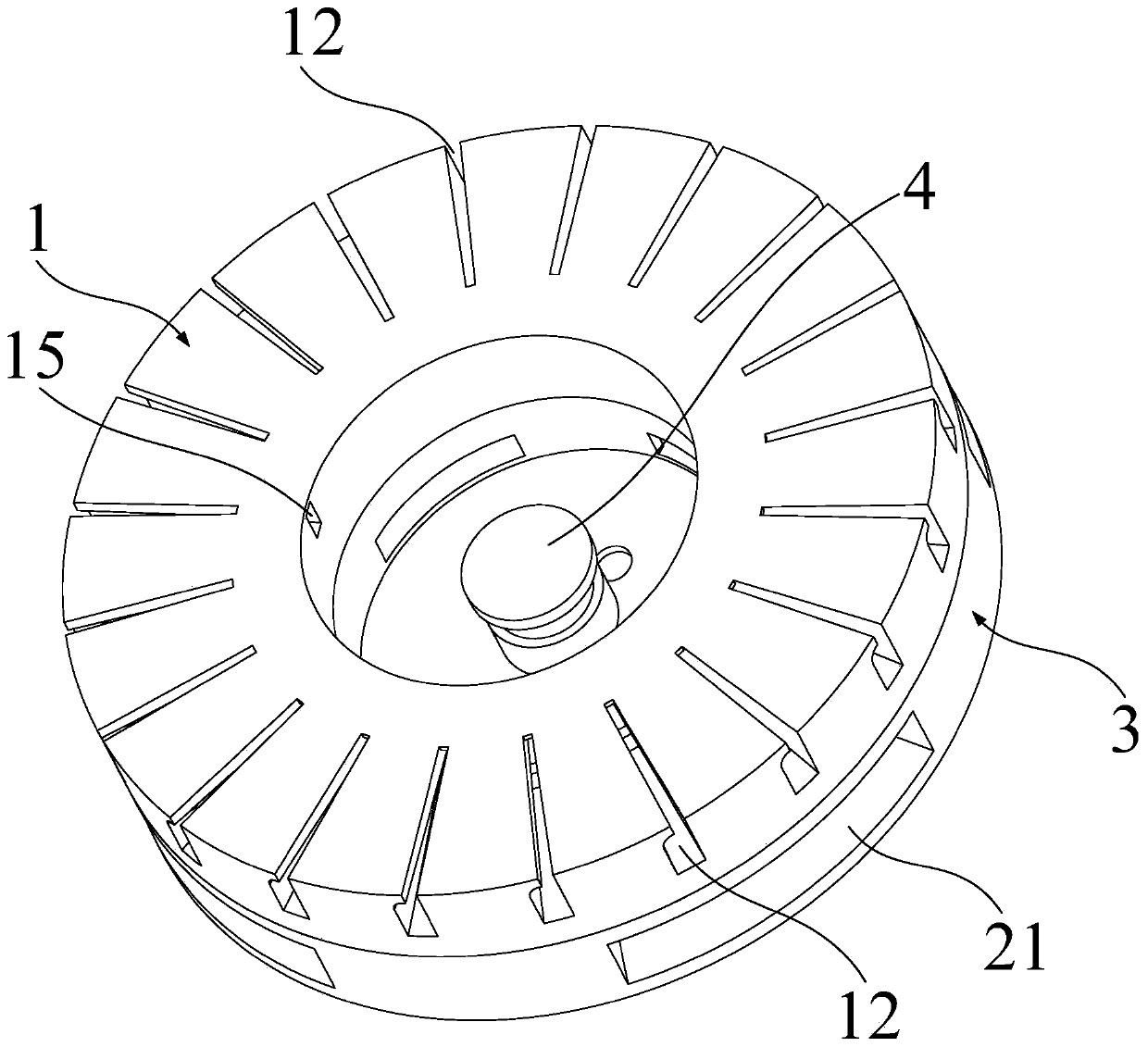

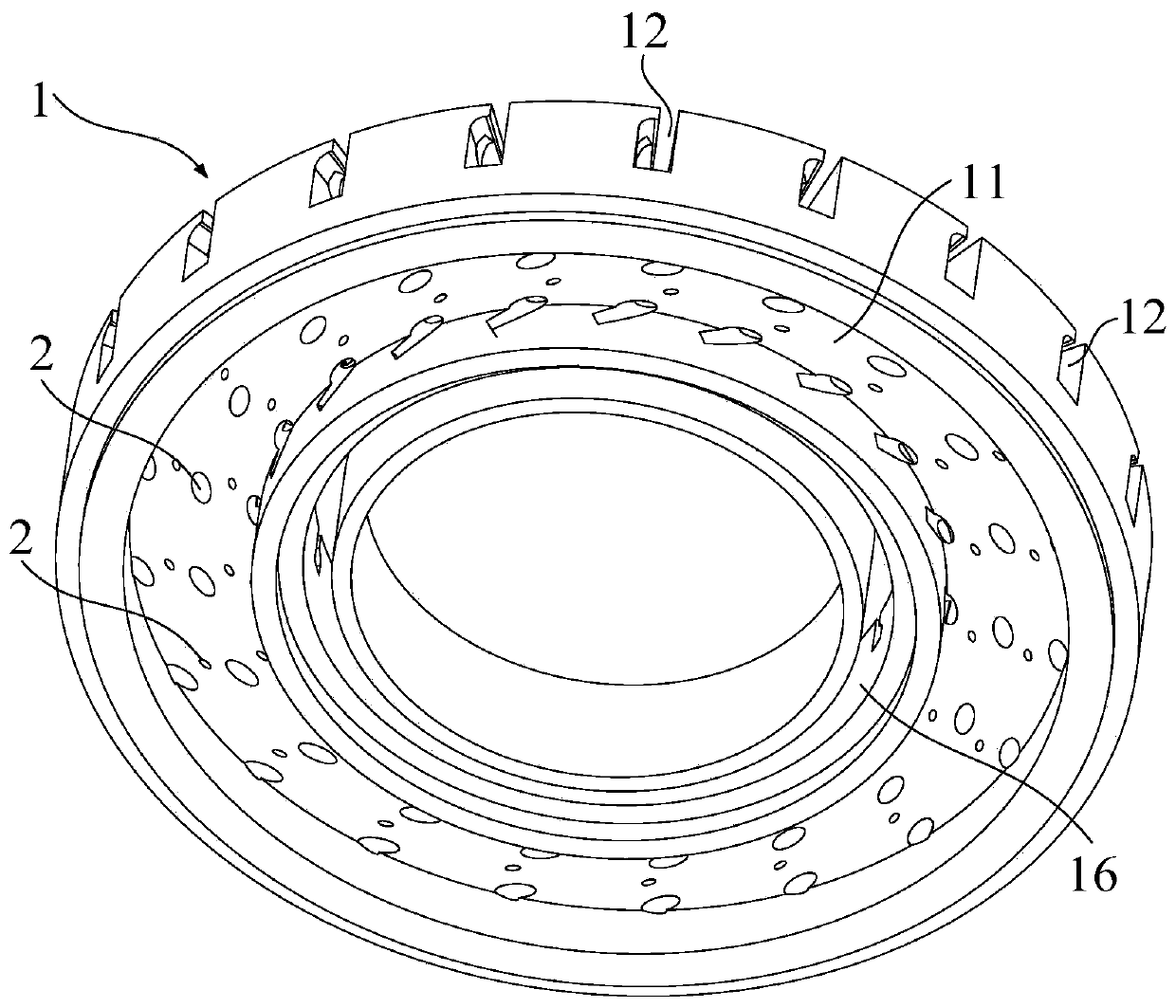

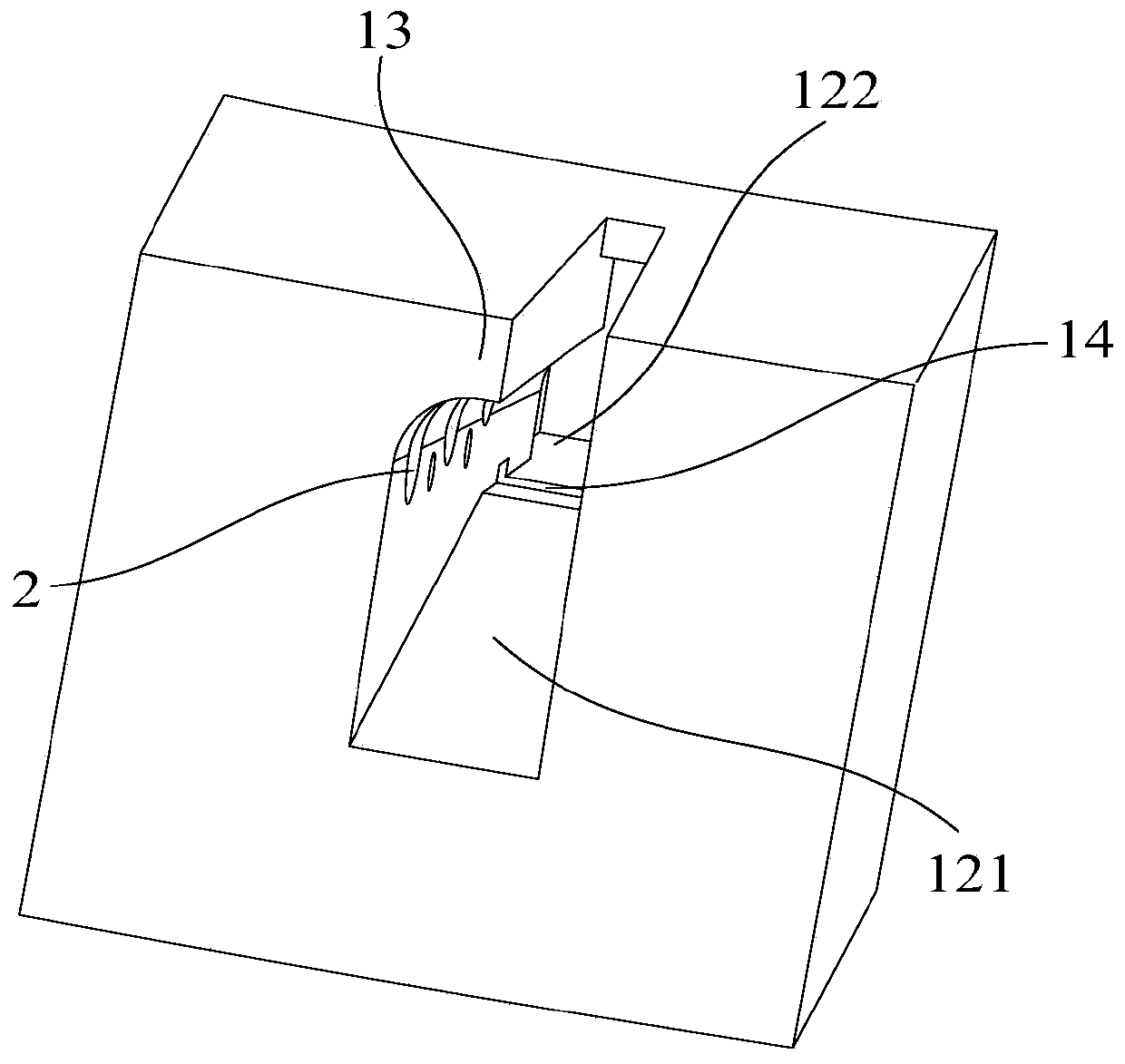

[0040] Such as figure 1 with figure 2 As shown, the present invention provides a cooker burner, which includes a fire cover body 1, a number of fire holes 2 are arranged inside the fire cover body 1, a gas cavity 11 is provided at the bottom of the fire cover body 1, and the upper surface of the fire cover body 1 There are several cutouts 12 arranged at the outer edge of the fire cover body 1. The notches of the cutouts 12 are located on the upper surface and the outer surface of the fire cover body 1. The fire holes 2 include main fire holes and flame stabilizing holes, and the outlet ends of all fire holes 2 are It communicates with the slot 12 and the inlet end of the fire hole 2 communicates with the gas cavity 11 .

[0041] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com