Composite material for heat or sound insulation and method for manufacturing such composite material

A composite material and isolation material technology, which is applied to composite materials for heat insulation or sound insulation and the field of manufacturing such composite materials, can solve the problems of surface, paint, anti-rust coating damage, etc., and achieve the effect of small cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

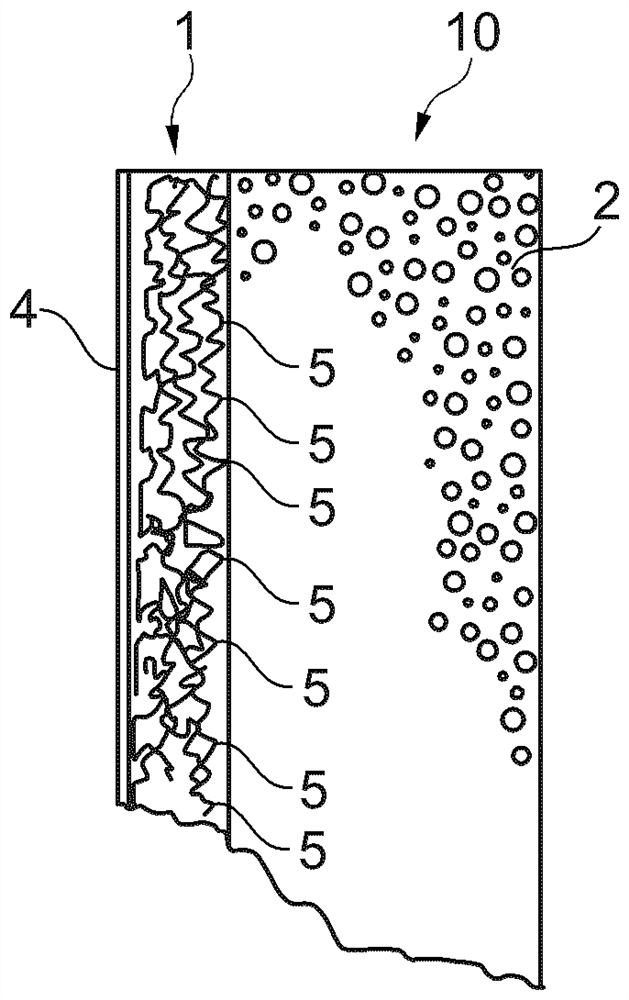

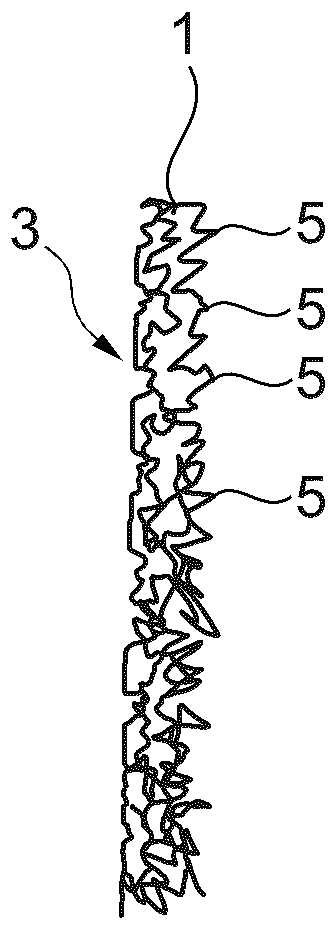

[0031] Figure 1a , Figure 1b and Figure 1c The first exemplary embodiment, the various production steps and the composite material 10 according to the invention are shown in different schematic side views. In a first embodiment, the composite material 10 consists of an insulating material 2 and a drainage formation 1 associated therewith. Composite material 10 can be contained in Figures 1a to 1c Additional layers, functional layers or elements not shown in . The composite material 10 according to the invention is used for thermal and / or sound insulation in vehicles, buildings or technical installations, for example in rail vehicles or aircraft. The composite material 10 has an overall planar, plate-shaped basic shape, ie the composite material 10 is used directly as a plate-shaped element or as a rolled product for further use as insulation material in various fields of application. The composite material 10 according to the invention comprises at least one layer of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com