Operation control method and system, readable storage medium, and compression and air conditioner systems

A technology of operation control and compressor, which is applied in the field of compression, can solve problems such as poor regulation, refrigerant cycle mismatch, throttle valve adjustment lag, etc., to avoid the calculation process and control process, simplify the overall control process, and avoid Effects of Mishandling Situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

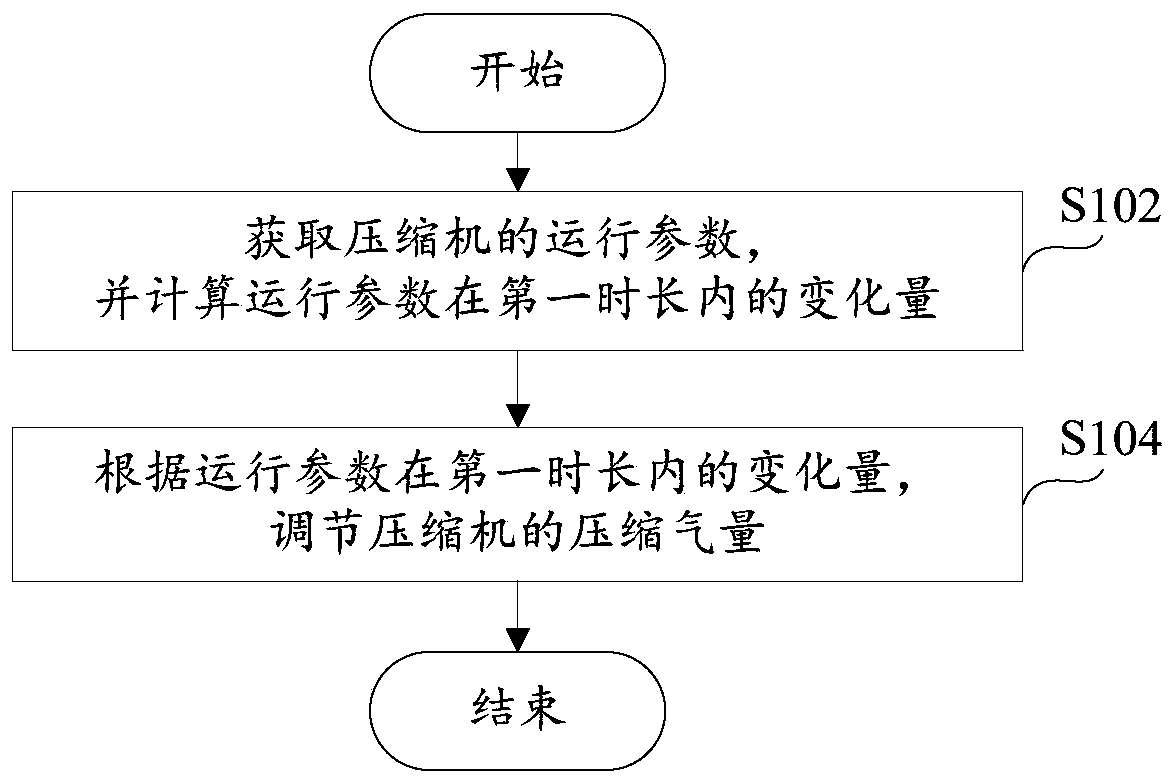

[0061] figure 1 A schematic flow chart showing the operation control method of the first embodiment of the present invention, such as figure 1 shown, including:

[0062] S102. Obtain the operating parameters of the compressor, and calculate the variation of the operating parameters within the first time period;

[0063] S104. Adjust the compressed gas volume of the compressor according to the change amount of the operating parameter within the first time period.

[0064] In this embodiment, first obtain the operating parameters of the compressor, and calculate the change of the operating parameters of the compressor within the first period of time; then judge whether the liquid-carrying condition of the compressor is Has a tendency to deteriorate. When the liquid-carrying situation has a tendency to deteriorate, reduce the compressed air volume of the compressor, thereby alleviating the liquid-carrying situation of the compressor to a certain extent, and ensure the stable o...

Embodiment 2

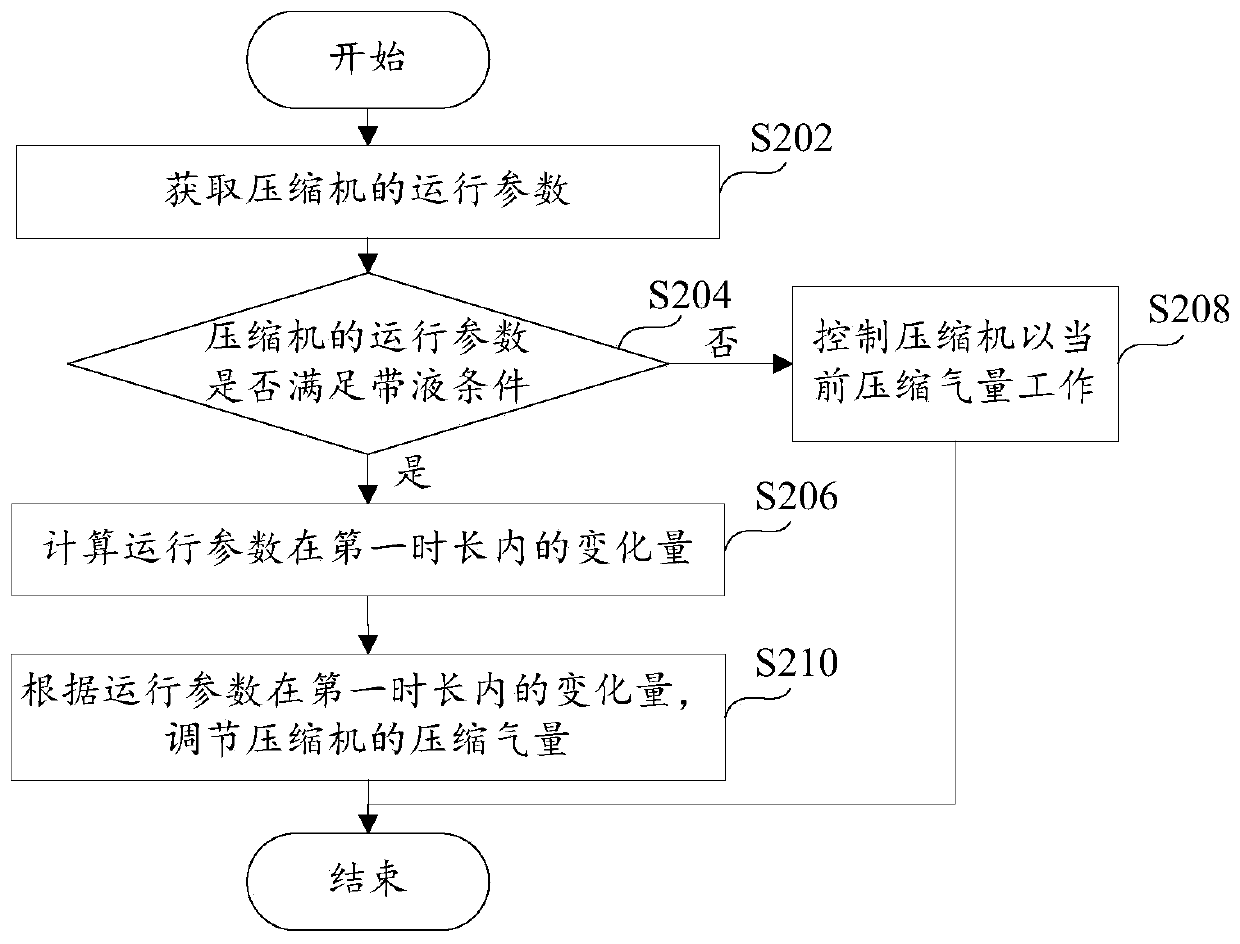

[0073] figure 2 A schematic flow chart showing the operation control method of the second embodiment of the present invention, such as figure 2 shown, including:

[0074] S202, acquiring the operating parameters of the compressor;

[0075] S204, judging whether the operating parameters of the compressor meet the liquid-carrying condition, if so, execute S206, if not, execute S208;

[0076] S206, calculating the change amount of the operating parameter within the first time period;

[0077] S208, controlling the compressor to work with the current compressed air volume;

[0078] S210. Adjust the compressed gas volume of the compressor according to the change amount of the operating parameter within the first time period.

[0079] In this embodiment, after the operating parameters of the compressor are obtained, it is firstly determined whether the compressor has a liquid-carrying condition. If there is no liquid in the compressor, it means that the compressor can run smoot...

Embodiment 3

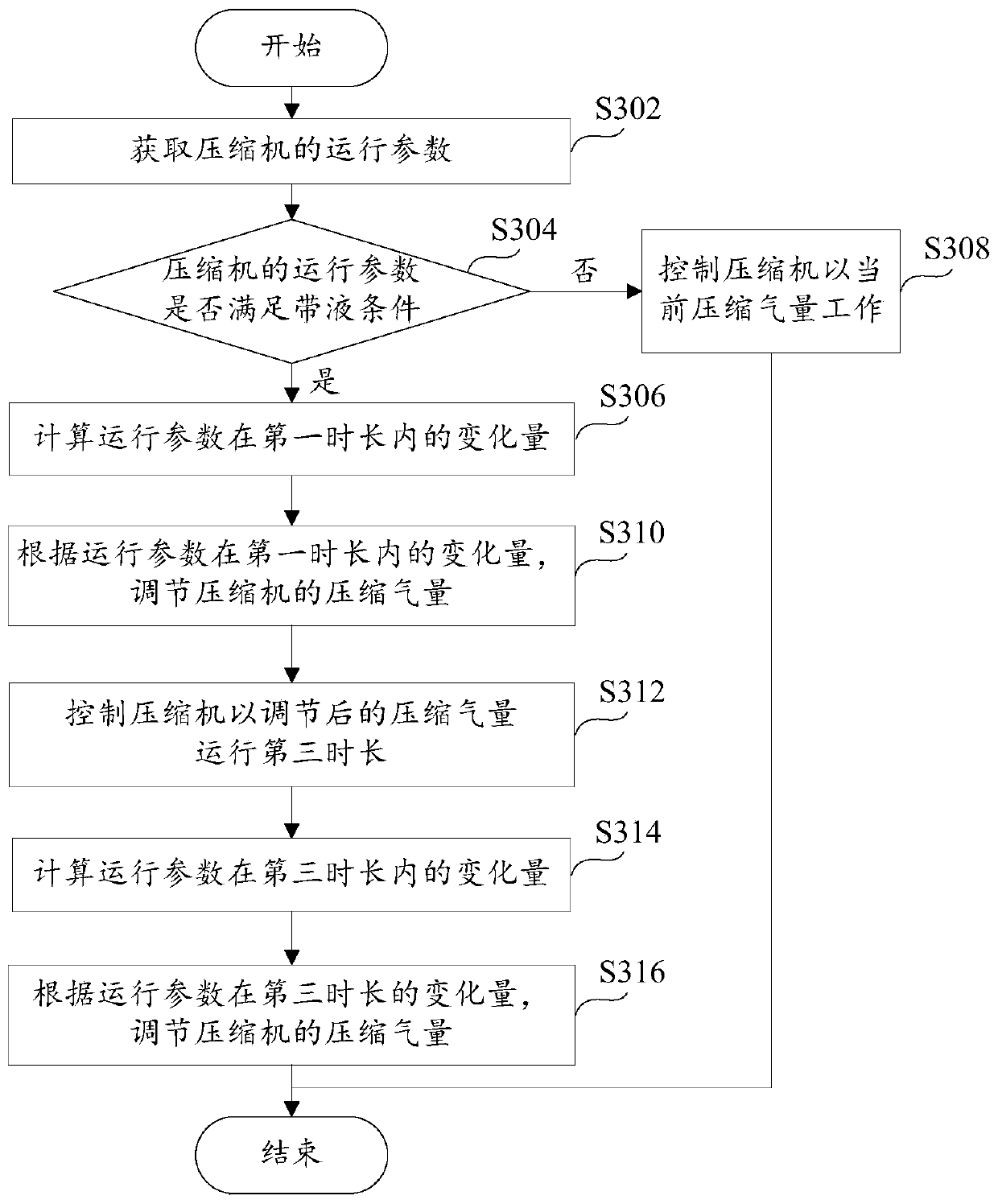

[0083] image 3 A schematic flow chart showing the operation control method of the third embodiment of the present invention, as image 3 shown, including:

[0084] S302, acquiring the operating parameters of the compressor;

[0085] S304, judging whether the operating parameters of the compressor meet the liquid-carrying condition, if so, execute S306, if not, execute S308;

[0086] S306, calculating the change amount of the operating parameter within the first time period;

[0087] S308, controlling the compressor to work with the current compressed air volume;

[0088] S310, adjusting the compressed gas volume of the compressor according to the variation of the operating parameters within the first time period;

[0089] S312, controlling the compressor to run for a third duration with the adjusted compressed air volume;

[0090] S314. Calculate the change amount of the operating parameter within the third time period;

[0091] S316. Adjust the compressed gas volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com