Three-dimensional laser scanning detection method for coke tower cylinder deformation

A technology of scanning detection and detection method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of lack of detailed description and unclear implementation methods, so as to ensure the safety of inspection personnel, a high degree of automation, and save downtime inspection costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

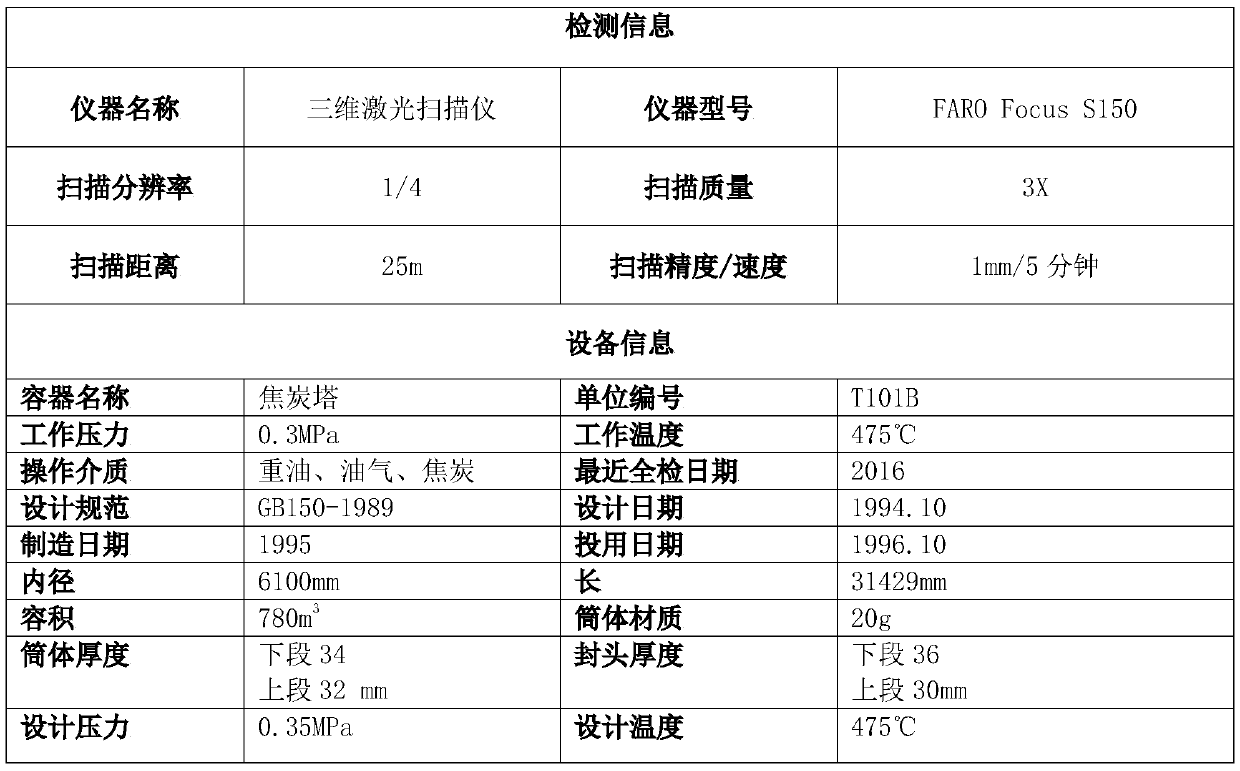

[0046]The basic information and testing equipment information of the coke drum tested are shown in Table 1. The coke drum was internally inspected in 2016. The maximum inner diameter measured by physical measurement method was 6300mm, the designed inner diameter was 6100mm, and the inner diameter increased by about 200mm. However, the deformation amount and position obtained by this detection method are relatively rough.

[0047] Table 1 Basic parameters of coke drum detection

[0048]

[0049] Since there is no actual measurement data of the original size of the coke drum, a three-dimensional model of the undeformed coke drum is established with reference to the design structure size.

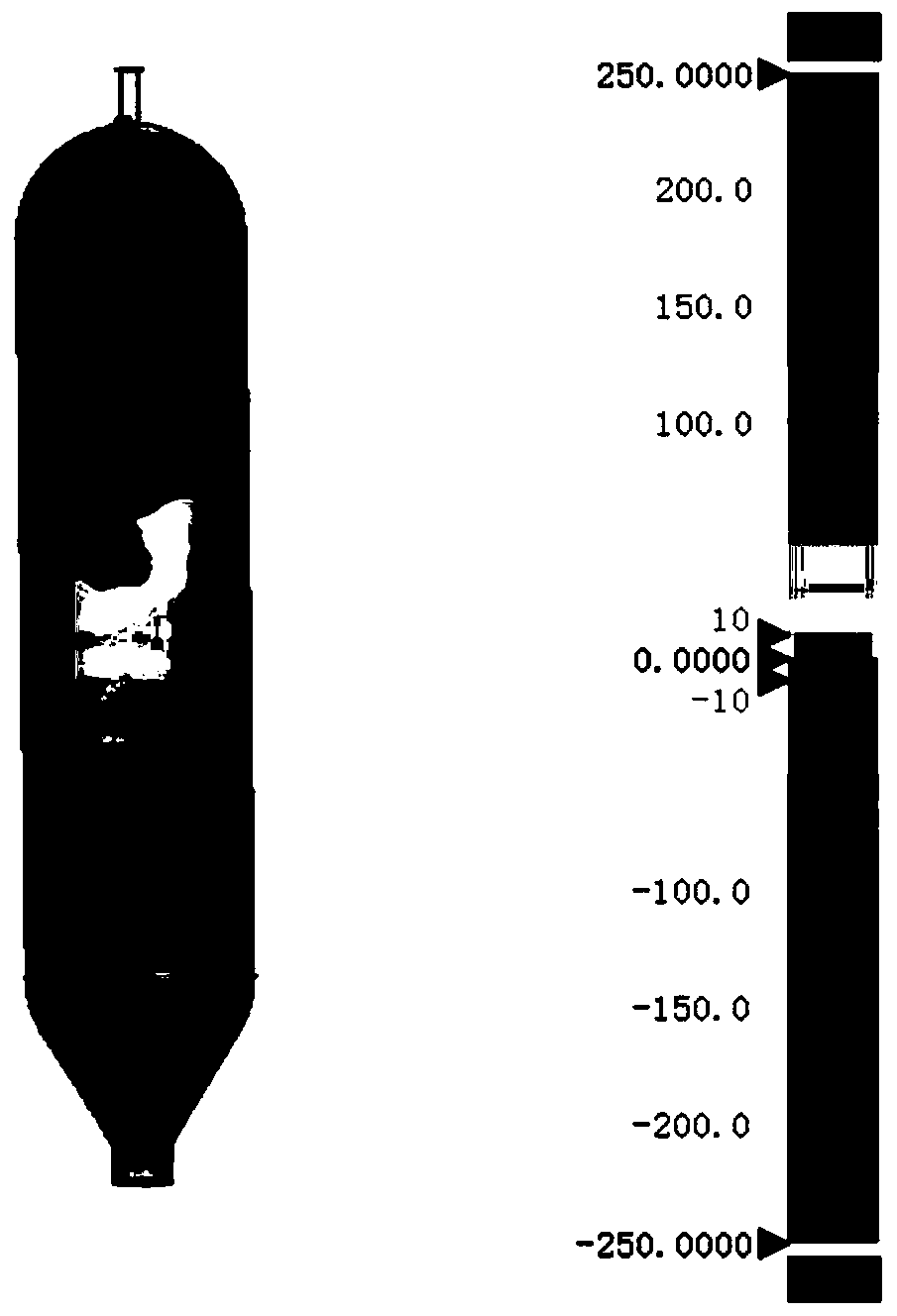

[0050] This method is used to detect the coke drum, and the point cloud data of the deformed coke drum body obtained according to the actual measurement results is compared with the three-dimensional model of the undeformed coke drum. The result is as figure 1 shown. Depend on figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com