Dual-motor pressure generating system of weight loading mechanism

A technology of loading mechanism and dual motors, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of poor reliability and stability, boring work, low degree of automation, etc., and achieve rapid and precise pressure building, accurate positioning and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

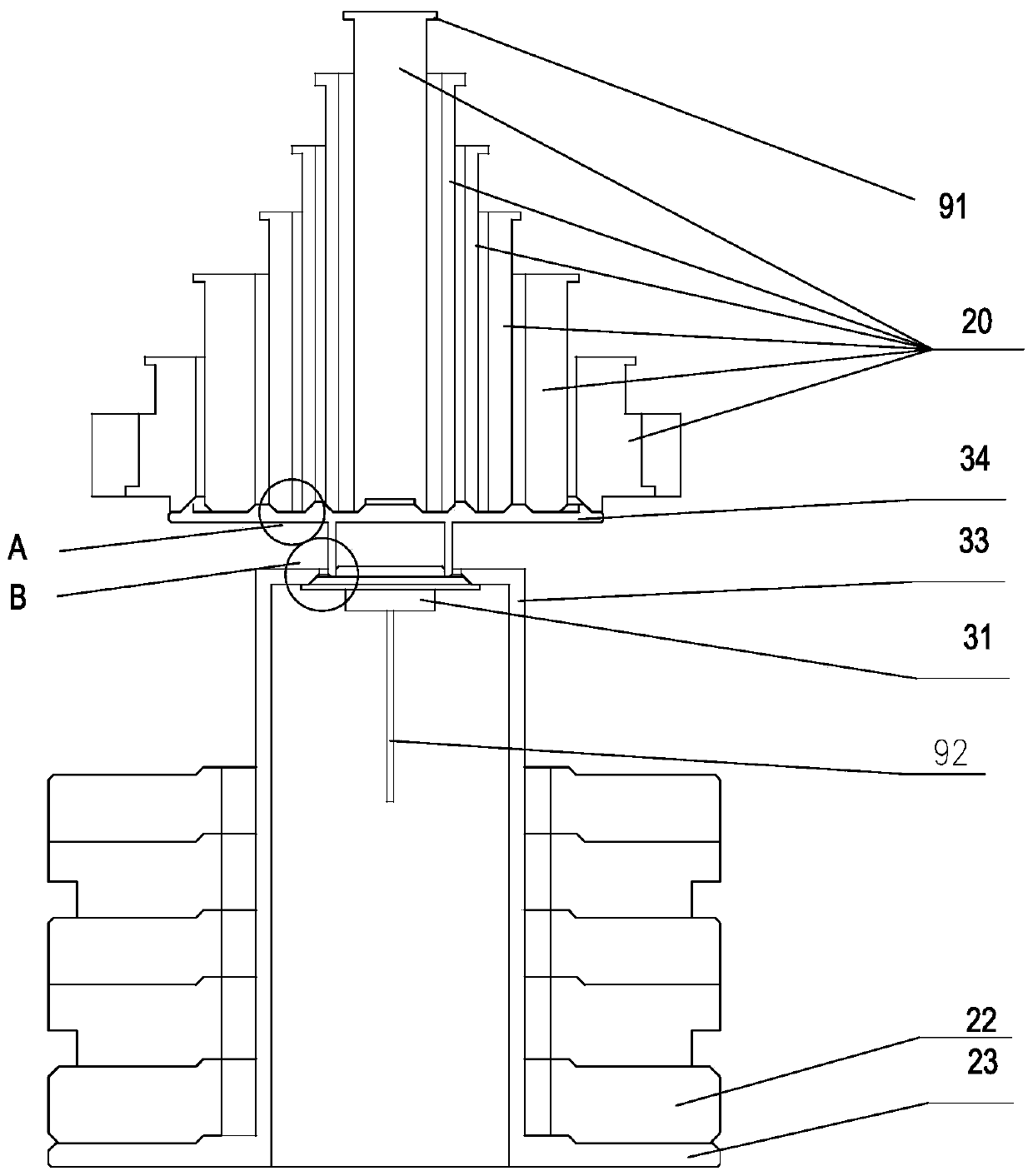

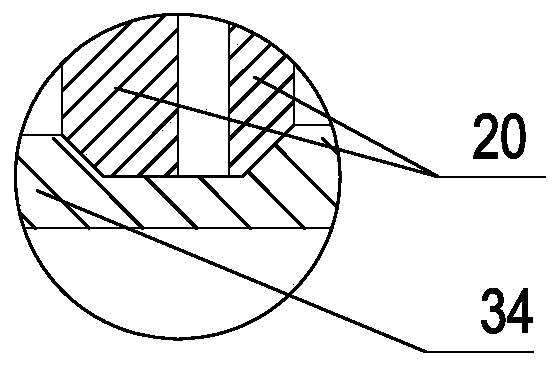

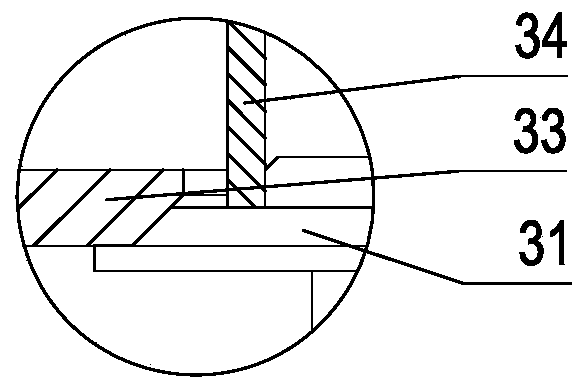

[0027] like Figure 1-7 . The combined weight loading mechanism shown in 9-11 includes a piston weight 31 connected to the lower piston rod 92 for weighing or pressure calibration; the upper part of the piston weight 31 is connected to the upper part of the cylindrical hanging basket weight 33 At the center of the barrel mouth; the outside of the bottom of the barrel wall of the hanging basket weight 33 is connected to a radial ring-shaped weight tray 23 , and the ring-shaped disc-shaped weights 22 are stacked on the weight tray 23 . The upper part of the piston weight 31 is also connected to a tray weight 34 above the hanging basket weight 33 through a connecting structure; a set of nested cylindrical weights 20 is arranged on the tray weight 34 . The disc weight 22 is provided with an independent disc weight loading and unloading unit. The cylindrical weight 20 is provided with an independent cylindrical weight loading and unloading unit. Wherein, the piston cylinder of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com