Six-element high-entropy oxide material for lithium ion battery and preparation method

A lithium-ion battery, six-element high-entropy technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of not finding high-entropy oxide powder, poor high-current charge and discharge performance, and reduced cycle life. Achieve the effect of improving cycle stability, low cost and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

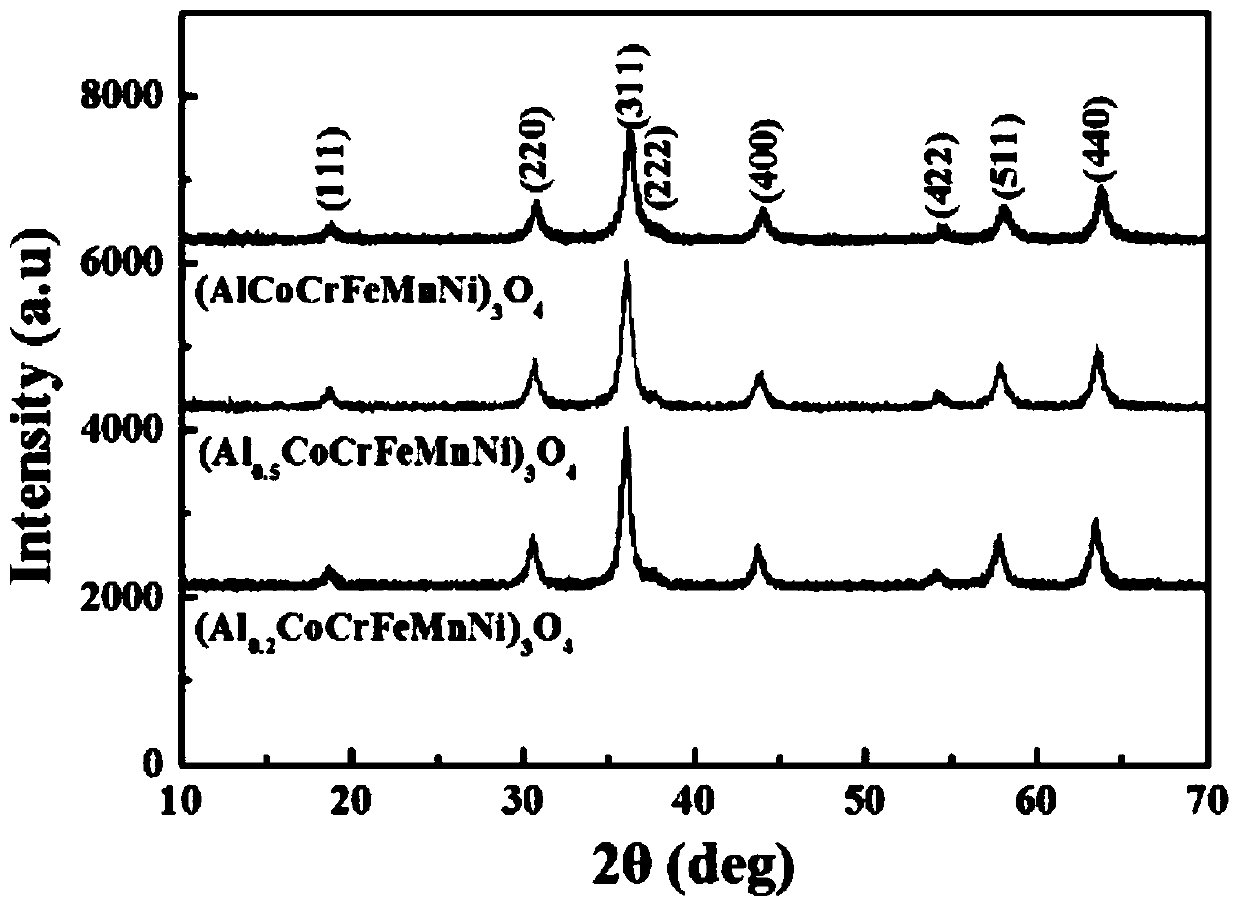

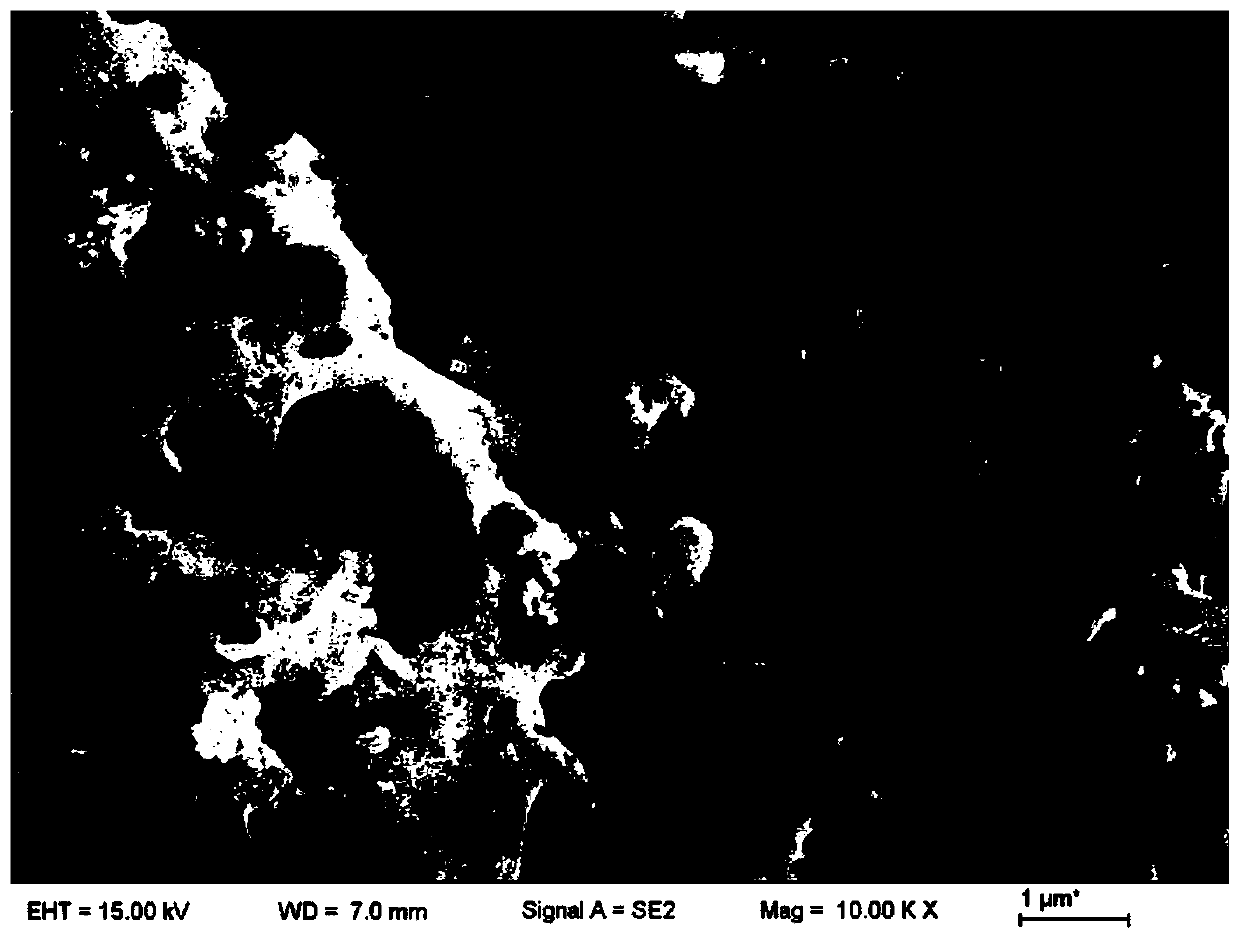

Embodiment 1

[0026] Adopt sol-gel method to prepare high-entropy oxide (AlCoCrFeMnNi) for lithium-ion battery negative electrode material described in the present invention 3 o 4 Powder material: weigh 9.37g of Al(NO 3 ) 3 9H 2 O, 7.28g of Co(NO 3 ) 2 ·6H 2 O, 10.04g of Cr(NO 3 ) 3 9H 2 O, 10.1g of Fe(NO 3 ) 3 9H 2 O, 6.25g of Mn(NO 3 ) 2 4H 2 O and 7.27g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of distilled water, stirred evenly by magnetic force to obtain a mixed solution of metal salts; then 21.00g of citric acid was weighed and added to the mixed solution, stirred by magnetic force for 0.5h, dried at 60°C to obtain a gel, and then the gel Place it in a muffle furnace at 500°C for 30 minutes to obtain a grain size of 93nm and a specific surface area of 32m 2 / g spinel-type high-entropy oxide (AlCoCrFeMnNi) 3 o 4 Powder.

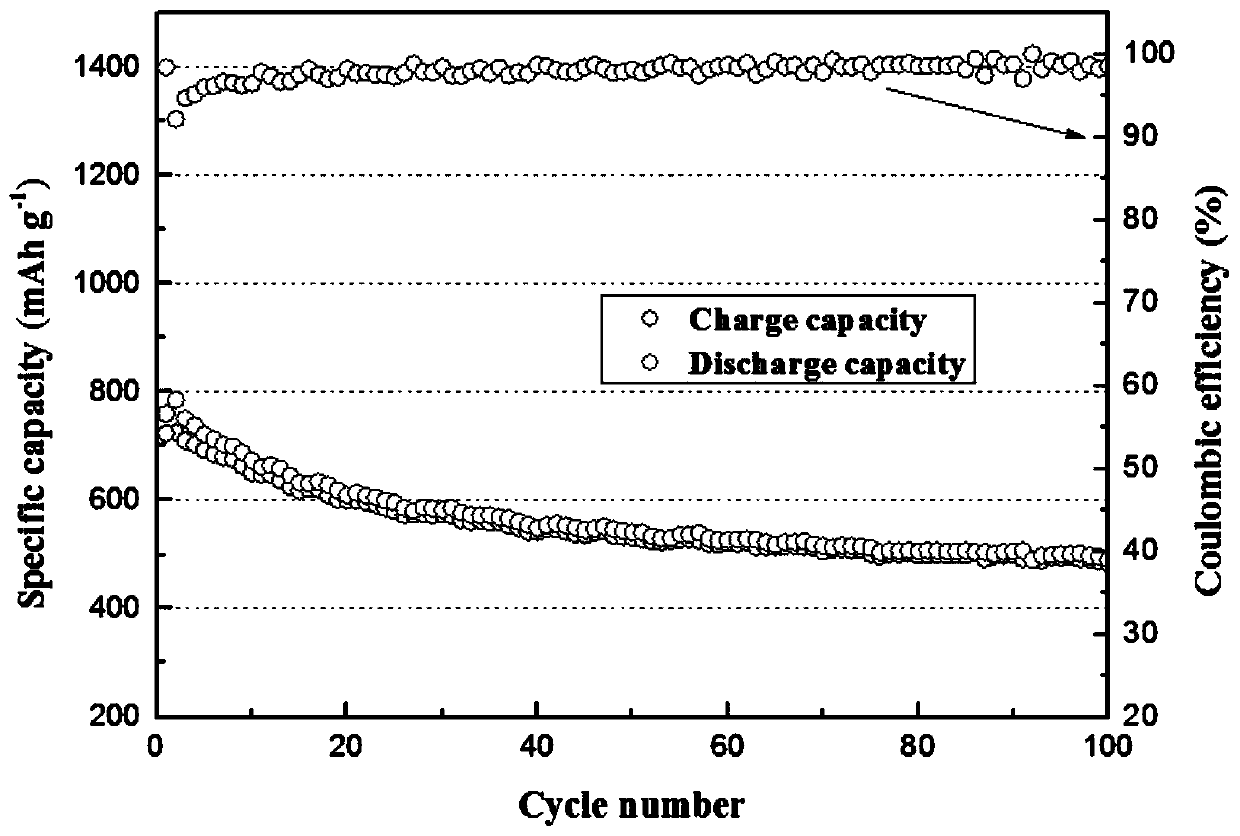

[0027] The active material (AlCoCrFeMnNi) 3 o 4 , carbon black (treated with nitric acid) and sodium alginate were mixed in a mass ratio of...

Embodiment 2

[0030] Adopt sol-gel method to prepare high-entropy oxide (Al 0.4 CoCrFeMnNi) 3 o 4 Powder material: weigh 3.75g of Al(NO 3 ) 3 9H 2 O, 7.28g of Co(NO 3 ) 2 ·6H 2 O, 10.04g of Cr(NO 3 ) 3 9H 2 O, 10.1g of Fe(NO 3 ) 3 9H 2 O, 6.25g of Mn(NO 3 ) 2 4H 2 O and 7.27g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of distilled water, stirred evenly by magnetic force to obtain a mixed solution of metal salts; then weighed 3.75g glycine and added to the mixed solution, stirred magnetically for 0.5h, dried at 60°C to obtain a gel, and then placed the gel in React in a muffle furnace at 450°C for 30 minutes to obtain a grain size of 103nm and a specific surface area of 35m 2 / g of spinel high-entropy oxides (Al 0.4 CoCrFeMnNi) 3 o 4 Powder.

[0031] The active material (Al 0.4 CoCrFeMnNi) 3 o 4 , carbon black (treated with nitric acid) and sodium alginate were mixed in a mass ratio of 6:2:2, ground and dispersed, evenly spread on copper foil, vacuum dried at 60...

Embodiment 3

[0033] Adopt sol-gel method to prepare high-entropy oxide (Al 0.2 CoCrFeMnNi) 3 o 4 Powder material: weigh 1.88g of Al(NO 3 ) 3 9H 2 O, 7.28g of Co(NO 3 ) 2 ·6H 2 O, 10.04g of Cr(NO 3 ) 3 9H 2 O, 10.1g of Fe(NO 3 ) 3 9H 2 O, 6.25g of Mn(NO 3 ) 2 4H 2 O and 7.27g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of distilled water, stirred evenly by magnetic force to obtain a mixed solution of metal salt; then weighed 1.5g of urea and added to the mixed solution, stirred magnetically for 0.5h, dried at 60°C to obtain a gel, and then placed the gel in React in a muffle furnace at 500°C for 30 minutes to obtain a grain size of 125nm and a specific surface area of 37m 2 / g of spinel high-entropy oxides (Al 0.2 CoCrFeMnNi) 3 o 4 Powder.

[0034] The active material (Al 0.2 CoCrFeMnNi) 3 o 4 , carbon black (treated with nitric acid) and sodium alginate were mixed in a mass ratio of 6:2:2, ground and dispersed, evenly spread on copper foil, vacuum dried at 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com