Capsule filling machine for filling capsules, and cleaning unit for use in a capsule filling machine

A cleaning unit and filling machine technology, which is applied in the capsule filling machine for filling capsules and the cleaning unit used in the capsule filling machine, can solve the problems of cost, concentration, and structure of the capsule dust collector, so as to overcome production deviation, Effects of Quick Error Analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

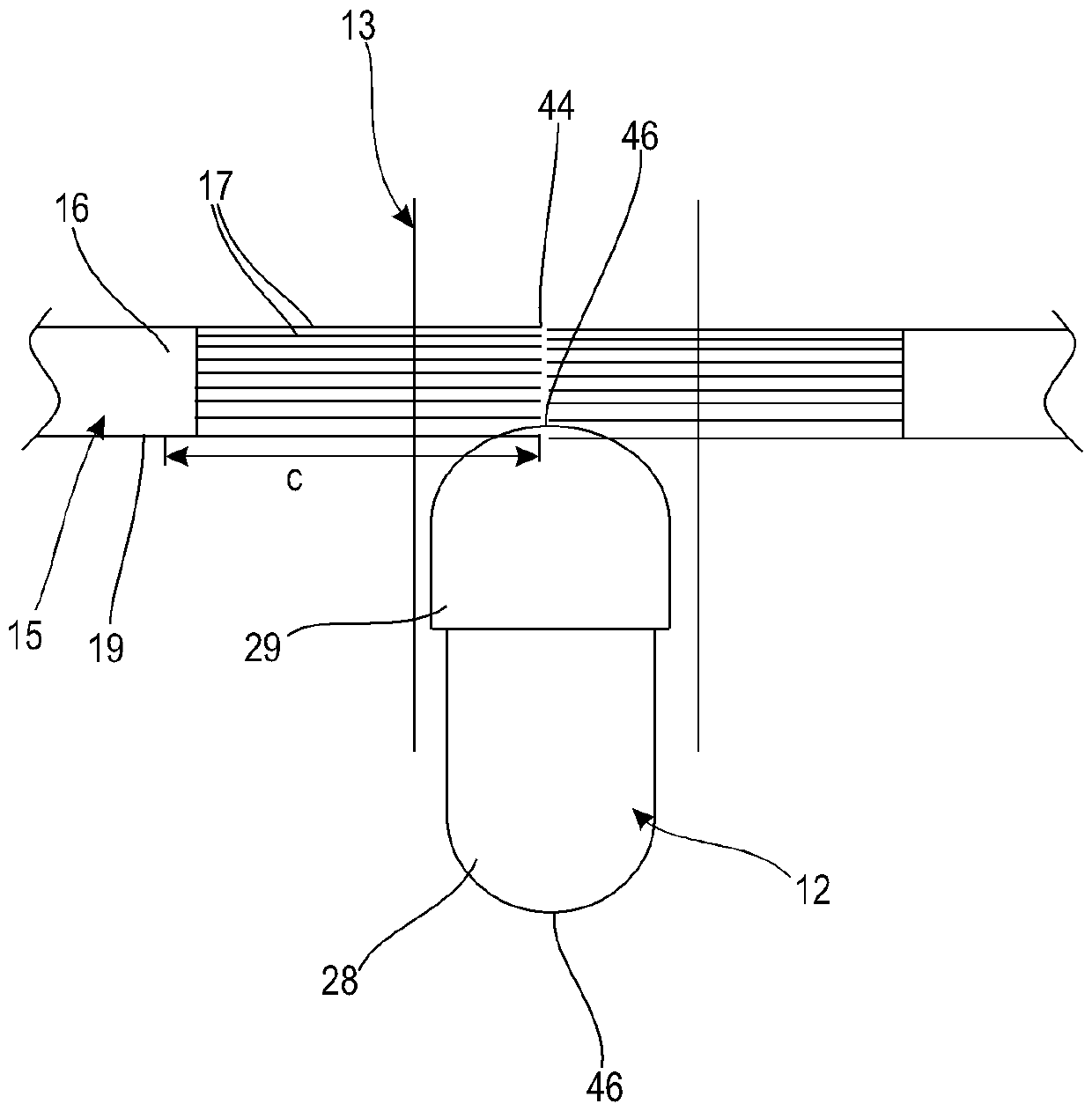

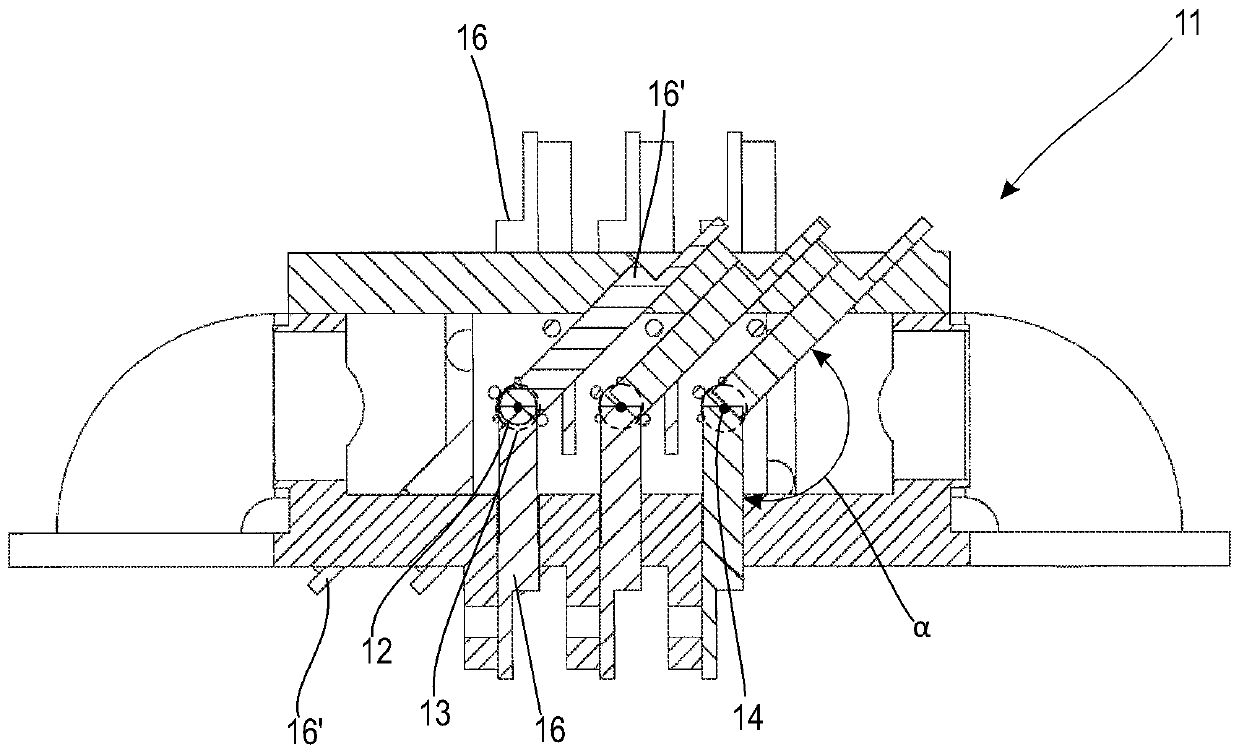

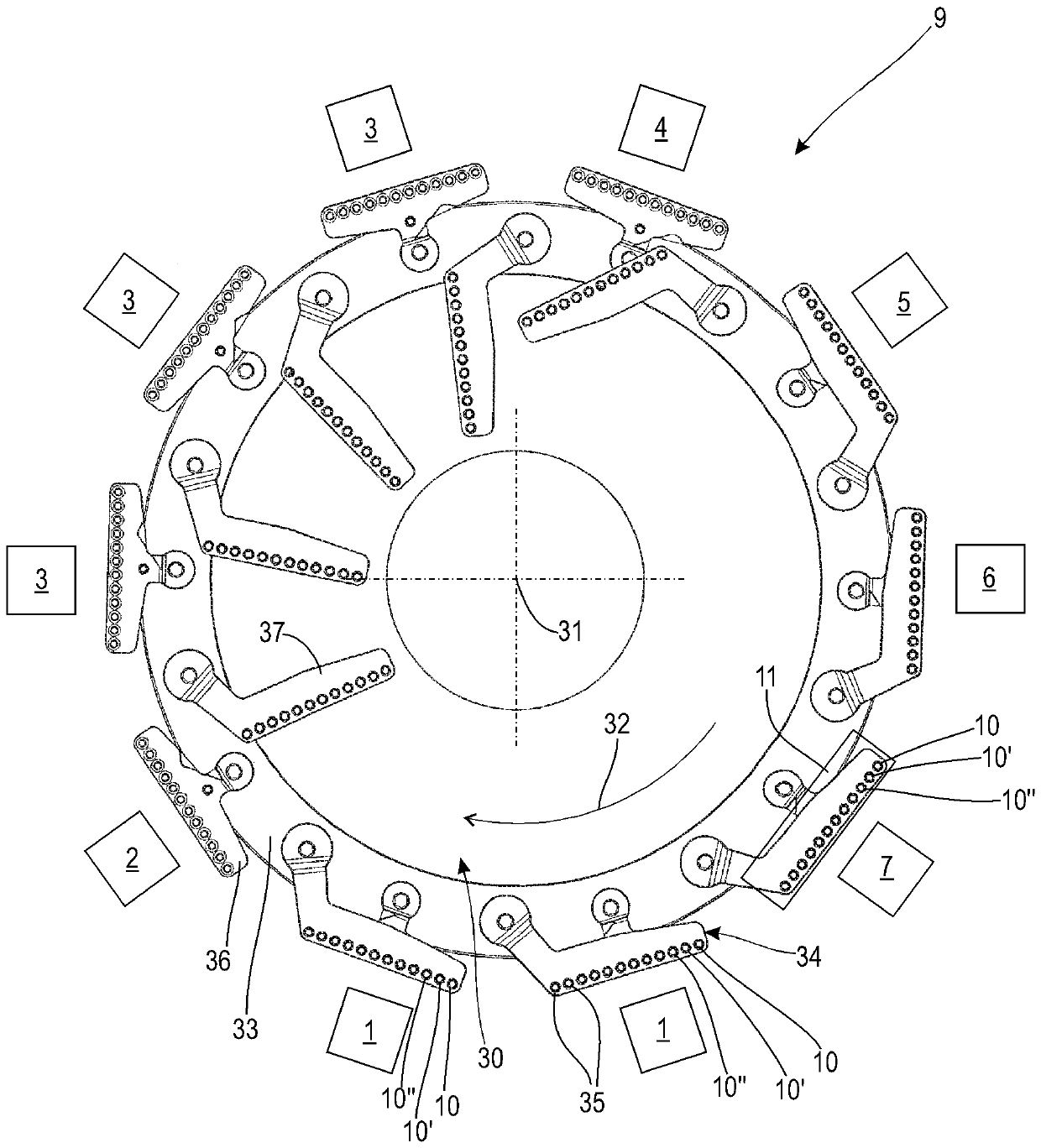

[0031] figure 1 Shown in a plan view for filling the capsule 12 with a filling ( figure 2 ) The middle part of the capsule filling machine implemented according to the present invention. The filler may be provided in the form of powder, granules, tablets or the like. Here, it can be a pharmaceutical preparation or a nutritional supplement. The capsule 12 is composed of a lower capsule 28 and an upper capsule 29 inserted on it ( Image 6 ), these two are made of hard glue, for example.

[0032] according to figure 1 The capsule filling machine 9 includes a rotating table 30, which can be rotatably driven in timed (getaktet, sometimes referred to as timed) steps, corresponding to the arrow 32, around a vertical axis of rotation 31. On the peripheral area 33 of the rotating table 30, a certain number of capsule receiving portions 34 are arranged at uniform angular intervals. In the illustrated embodiment, ten capsule receiving portions 34 are provided in total. Another amount ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com