Profile drilling machine convenient for drill rod switching

A drilling machine and profile technology, which is applied in the direction of drilling/drilling equipment, boring machine/drilling machine parts, metal processing machinery parts, etc., can solve the problems of inconvenient use, achieve simple and fast operation, prevent safety accidents, and ensure interception effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

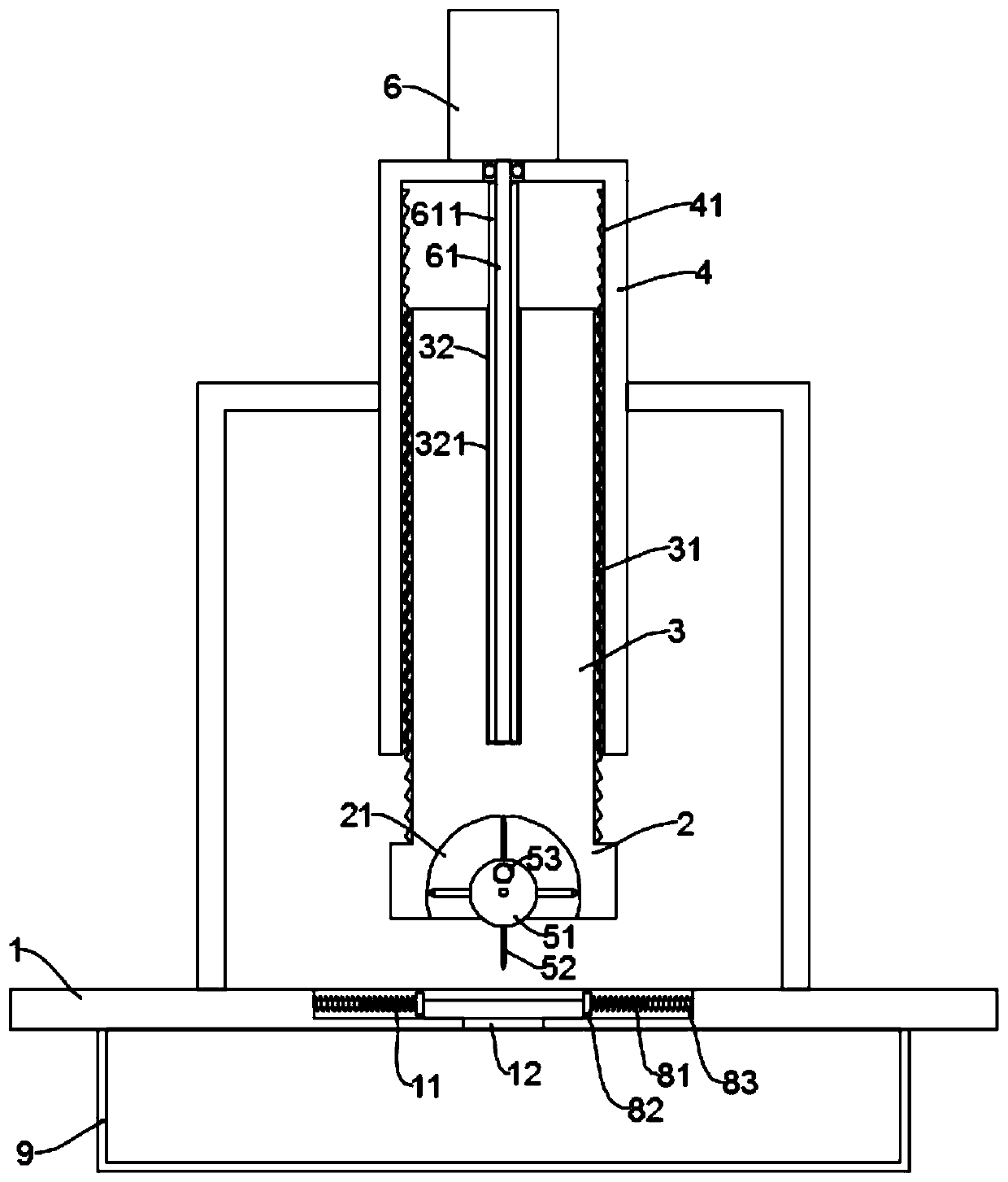

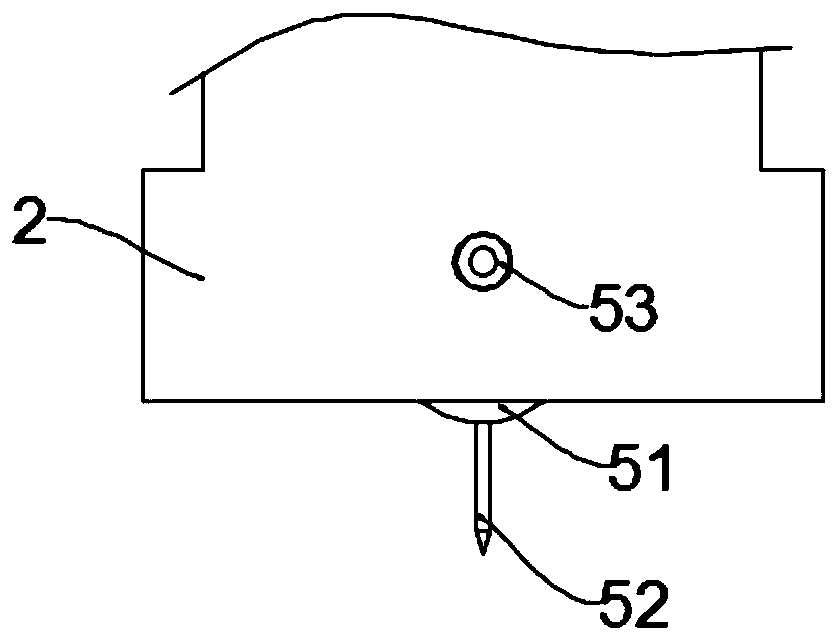

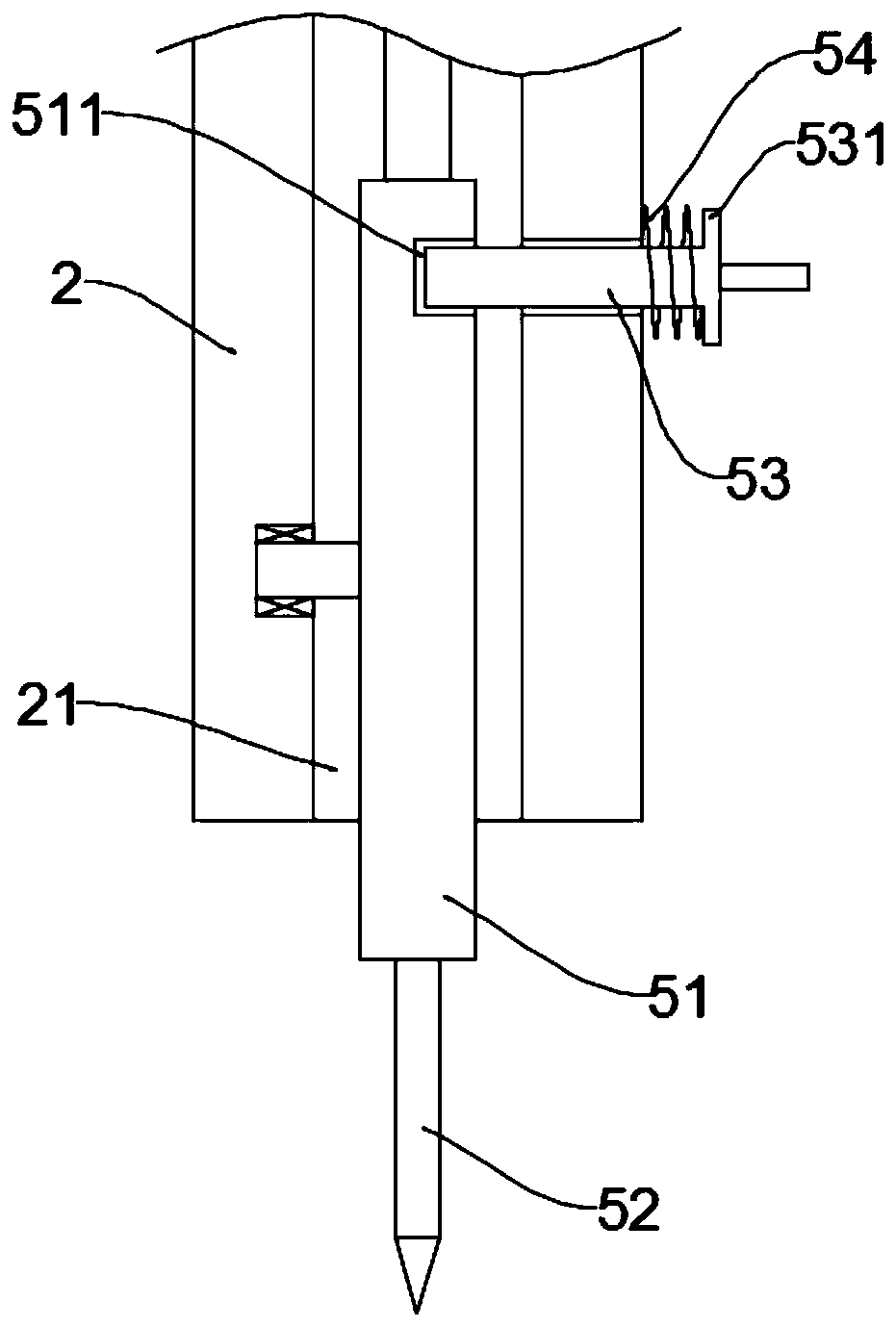

[0024] see Figure 1~4 , in an embodiment of the present invention, a profile drilling machine that is convenient for switching drill rods, includes a workbench 1, a storage slot 11 is provided on the worktable 1, and a drilling assembly is arranged above the storage slot 11; the drilling assembly It includes a base 2, which is driven by a screw-in drive assembly; the base 2 is provided with a cavity 21, and a turntable 51 is installed in the cavity 21, and a positioning mechanism for limiting the rotation of the turntable 51 is arranged on the base 2 , that is, the positioning mechanism can be used to fix the turntable 51 to limit its rotation; part of the turntable 51 protrudes from the cavity 21, and a plurality of drills with different diameters are equidistantly fixed on the circumferential surface of the turntable 51 along the circumferential direction. Rod 52, so that when in use, it can be rotated by turning the dial 51, so that the drill pipe 52 to be used is located ...

Embodiment 2

[0032] see Figure 5 , the embodiment of the present invention is expanded on the basis of embodiment 1, specifically:

[0033] Part of the waste slag will splash outward during the profile drilling process, which is likely to cause safety accidents. In order to avoid this situation, in this embodiment, the periphery of the base 2 is provided with a protective cover, and the protective cover is connected to the base through the connecting rod. 2 connection, so that it can be raised and lowered together with the base 2, so that the splashed waste residue can be effectively intercepted during the drilling process.

[0034] Further, the protective cover includes an upper cover body 71 and a lower cover body 72, the upper part of the lower cover body 72 is slidably inserted in the lower part of the upper cover body 71 and connected with the upper cover body 71 through a connecting spring 73, so that it can ensure The tight fit between the protective cover and the workbench 1 ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com