Abrasive belt polishing machine

An abrasive belt polishing and rotating body technology, applied in abrasive belt grinders, grinding/polishing equipment, grinders, etc., can solve problems such as disassembly and assembly of rotary joints, inconvenient maintenance, etc., to ensure long-term stable operation, improve service life, Improve the effect of fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

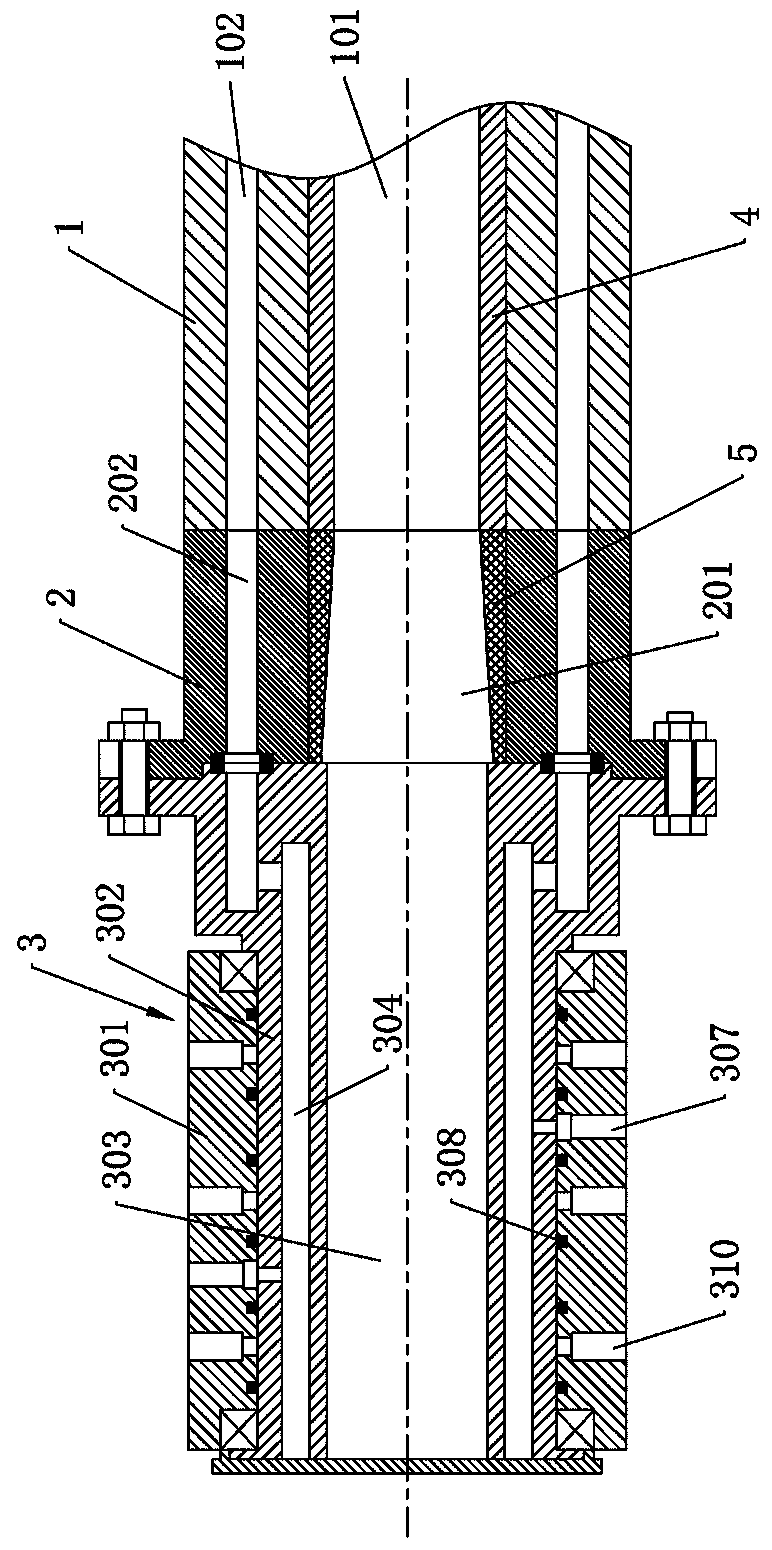

[0027] Example: such as figure 1 , figure 2 and image 3 As shown, an abrasive belt polishing machine includes a main shaft 1, a transition joint 2 and a rotary joint 3. The main shaft 1 is a hollow shaft, and the center of the main shaft 1 is provided with a first through hole 101 axially penetrating through it. The rotary joint 3 is located at the end of the main shaft 1, and the other end of the main shaft 1 is equipped with a large disc and a grinding head driven by an air cylinder. The main shaft 1 is horizontally installed on the frame through the bearing seat, and the rotary joint 3 is connected with a compressed air generator, such as a high-pressure air pump .

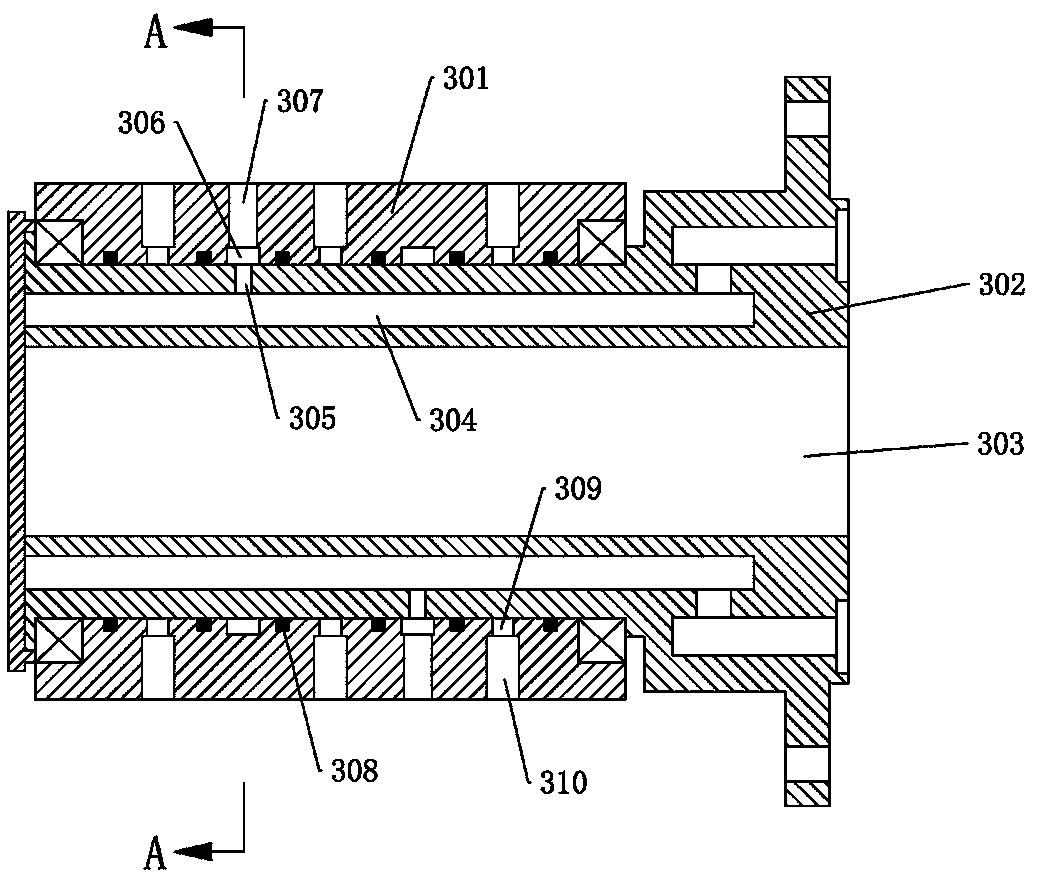

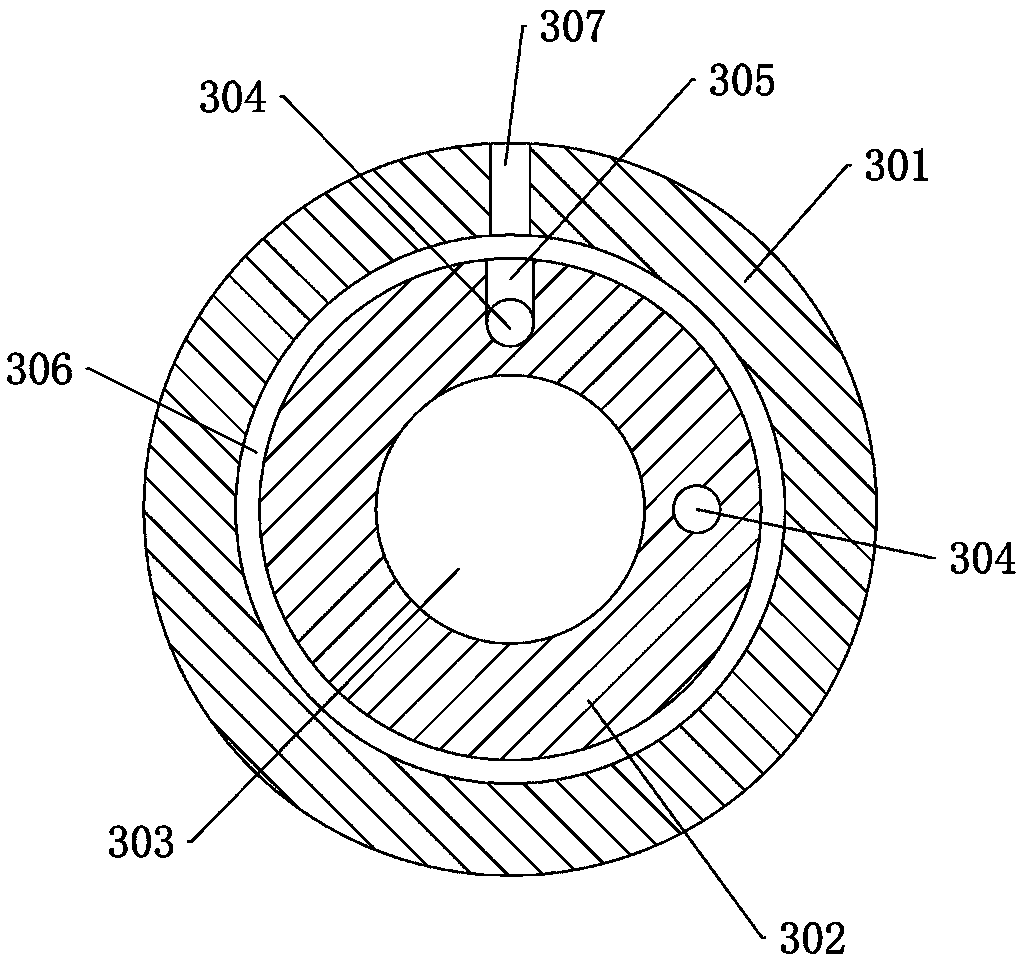

[0028] Such as figure 2 As shown, the rotary joint 3 includes a fixed body 301 and a rotating body 302. The fixed body 301 is sleeved on the outside of the rotating body 302, and is mounted on the rotating body 302 through a rotating shaft, and the two rotate relatively. The rotating body 302 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com