Automatic injection-compression process of commutator

A commutator and automatic technology, applied in the field of commutators, can solve problems such as low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

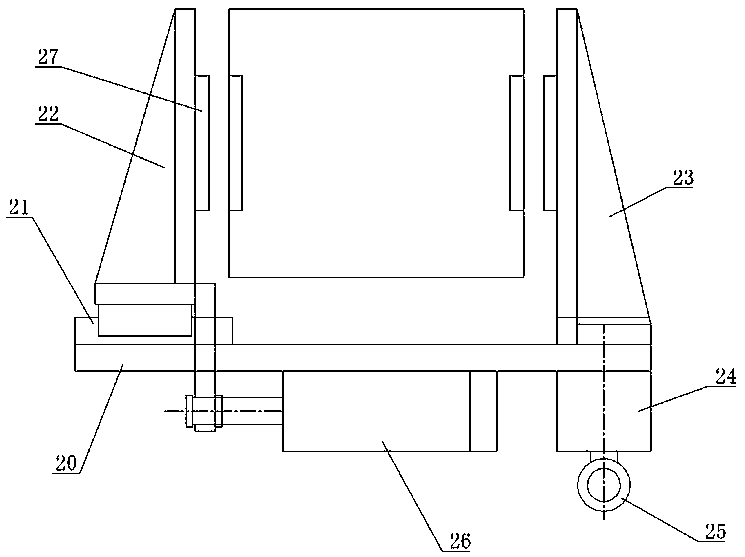

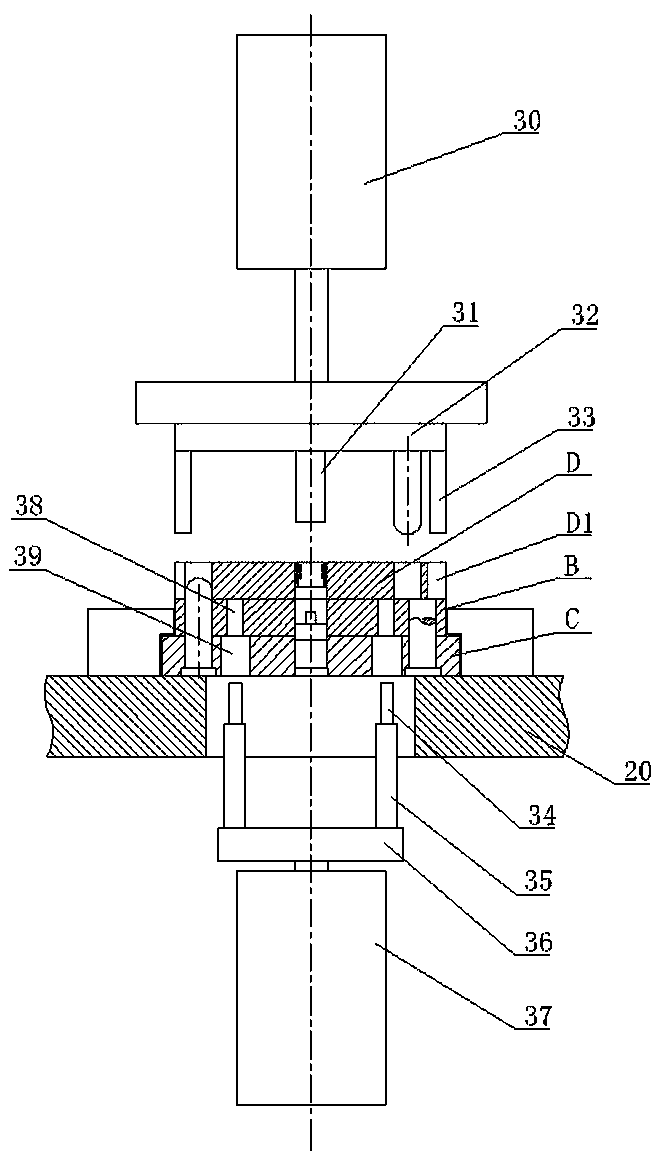

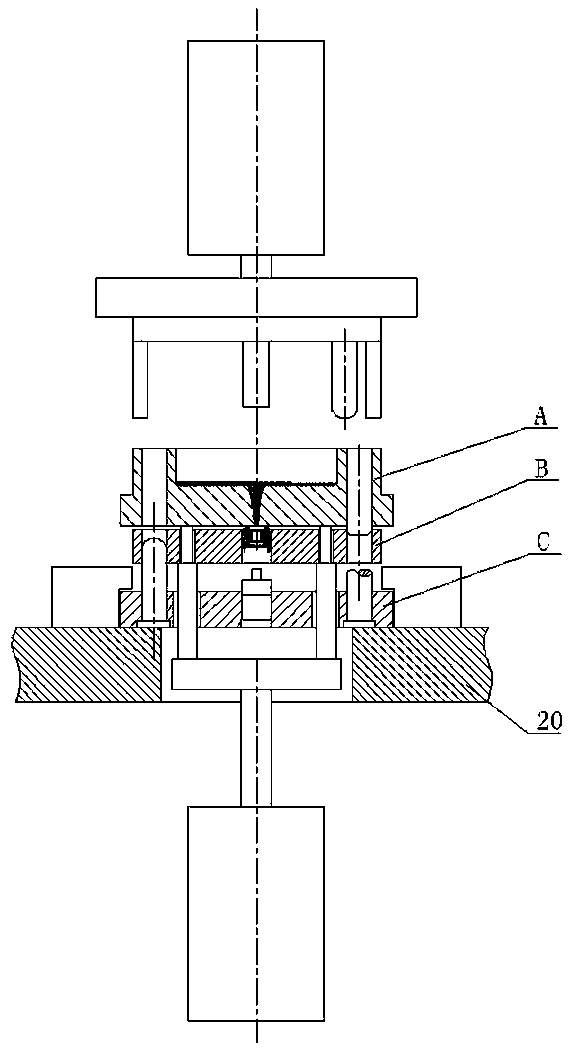

[0018] As shown in the figure, in the commutator automatic injection process of the present invention, the left injection waiting station 12, the right injection waiting station 14, the product output waiting station 10, the separation and closing station are arranged in an L shape around the robot 0. Mold waiting station 6, waste removal waiting station 8 and upper workpiece station 5, the worktable 20 is also L-shaped, the arm of the robot 0 is connected to the clamp 17, and the clamp 17 is used for clamping the injection mold and installing the material cup , the left side of the robot 0 is provided with a bakelite powder weighing mechanism 16, the left pressure injection station 13 is provided with a left pressure injection station 13 behind the left pressure injection waiting station 12, and the left pressure injection station 13 is equipped with a left press and a push injection The mold enters and exits the cylinder 1 of the left injection station 13, and the right injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com