Backing-free top block for film laminating machine

A technology of laminating machine and top block, which is applied in synthetic resin layered products, lamination devices, lamination and other directions, can solve the problems of affecting work efficiency, insufficient application effect, waste of resources, etc., and achieves stable and reliable operation and application. Good effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

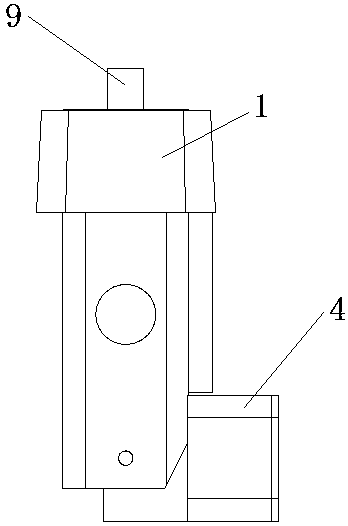

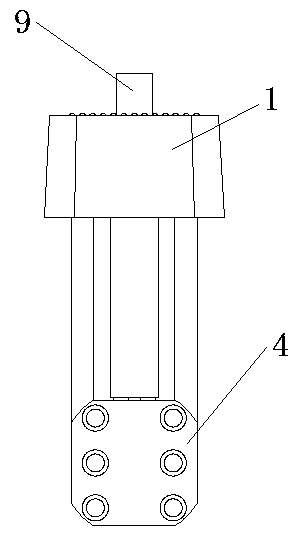

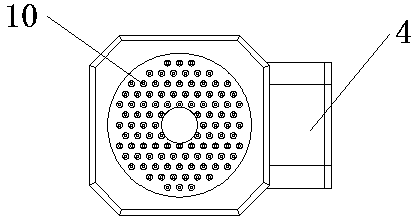

[0032] Such as Figure 1-5 As shown, the backing-free top block for the laminating machine includes a top block main body 1 and a spacer block 4, a rubber pad 10 is arranged in the center of the top of the top block main body 1, and a hole is opened in the middle of the rubber pad 10; Straight driving rack channel 11 and driven rack channel 12, a gear groove (not shown in the figure) is set between the driving rack channel 11 and driven rack channel 12, and the gear groove is located at the center hole of the rubber pad 10. Below, a gear 8 is arranged in the gear groove, and the gear 8 is installed on the top block main body 1 by the gear pin shaft 7. The driving rack 9 is arranged in the driving rack channel 11. The top of the driving rack 9 is bent, and the top of the driving rack 9 is bent. The folding section is located directly below the hole in the middle of the rubber pad 10, the lower part of the driving rack 9 meshes with the gear 8, and the spring 2 and the driven ra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap