A large rotary printing machine

A printing machine, a large-scale technology, applied in the direction of rotary printing machine, printing machine, transfer printing, etc., can solve the problems that affect the printing quality, the thickness of the self-adhesive base material cannot be completely uniform, and the printing quality has a deep impact, so as to achieve Solve the effect of uneven printing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

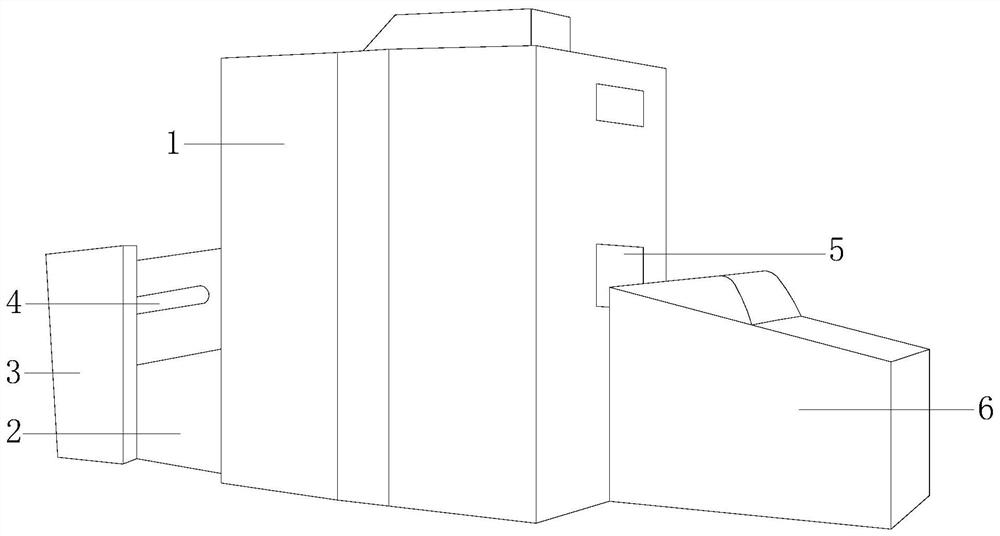

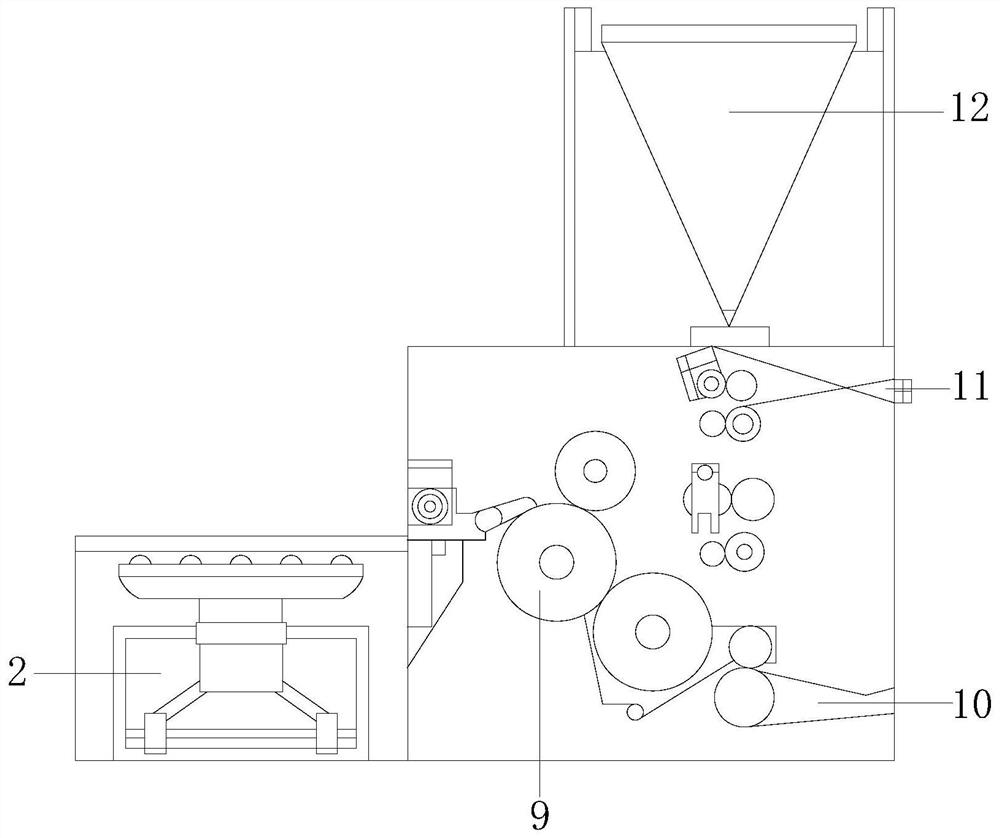

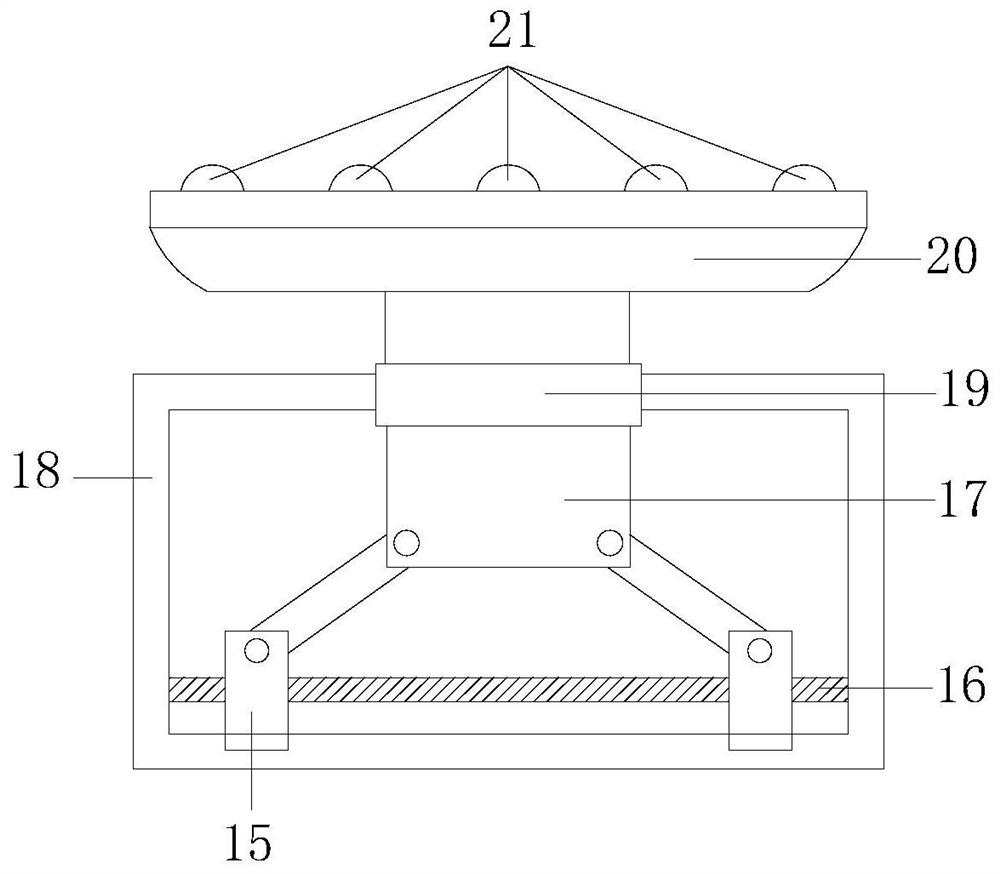

[0020] see figure 1 , the present invention provides a large rotary printing machine, the structure of which includes: a printing machine body 1, a pressure balance device 2, a conveying table 3, a roller 4, an input window 5, a feeder 6, and the side of the printing machine body 1 is connected to a The pressure balance device 2, the pressure balance device 2 is connected with the conveying platform 3, the conveying platform 3 is provided with a roll 4, the input window 5 is located at the side of the printing machine body 1 and connected with it, the feeder 6 is connected with the printing machine body 1, and the printing machine body 1 On the one hand, as the main structure of the equipment, it is used for the shell structure and protection of the equipment, on the other hand, it is also the core structure of the equipment, and is responsible for the printing work of the equipment. For the conveying work after the printed product is completed, the roll 4 is used to wind the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com