Automobile front axle

A technology for axles and automobiles, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of the paint surface of the axles detaching from rust, difficult to walk, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

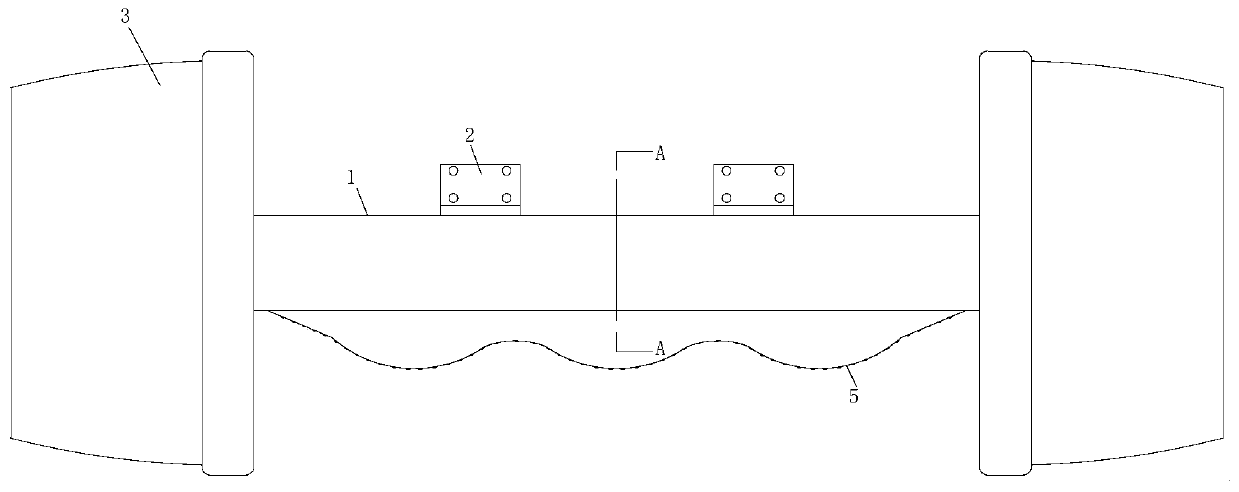

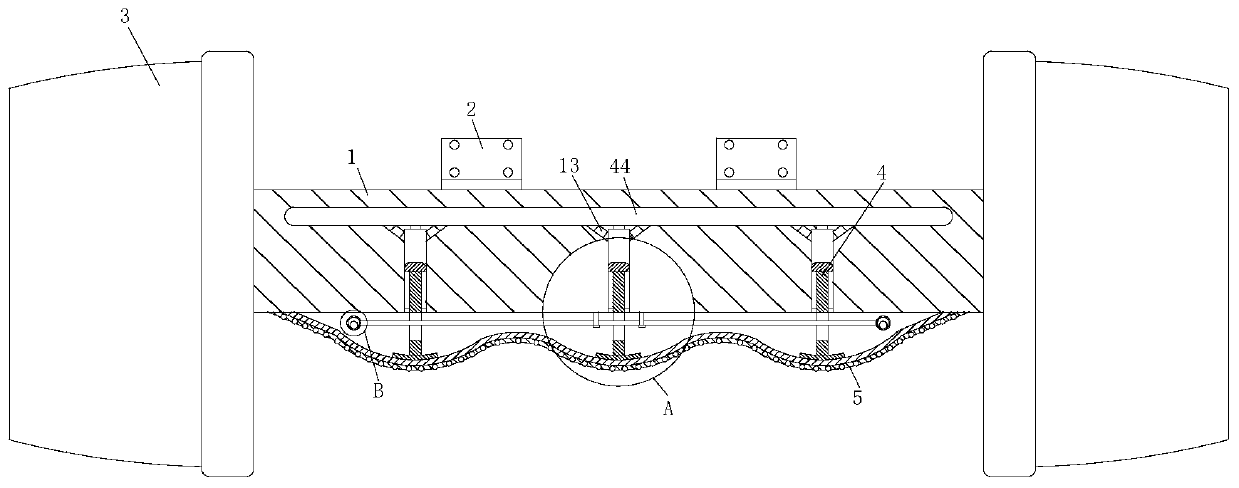

[0022] see Figure 1-5 The present invention provides a technical solution: a front axle of an automobile, including an axle body 1, a connector 2 welded on the upper wall of the axle body 1, and wheel hubs 3 installed at both ends of the axle body 1. A crash bearing mechanism 4 is arranged on the axle body 1 , and a mud removal mechanism 5 is arranged on the lower side of the axle body 1 .

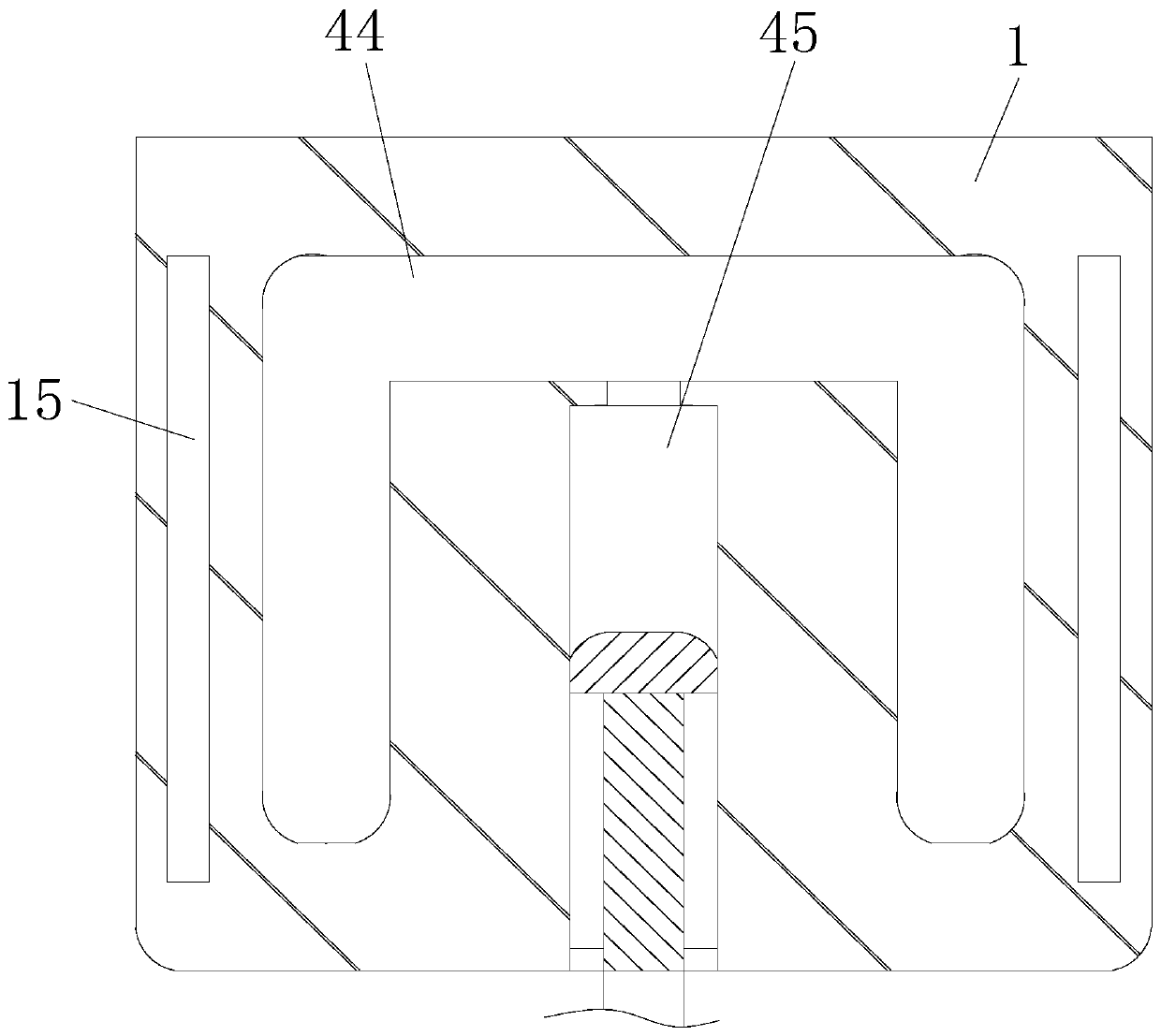

[0023] The impact bearing mechanism 4 includes a web 41 for providing mechanism protection, a T-shaped bar 42 for providing impact conduction, a piston 43, an inverted U-shaped cavity 44, an insertion hole 45, a limit ring 46 and a compression spring 47. The edge of the web 41 is welded on the edge of the lower surface of the axle body 1, the web 41 has three convex shells 48 protruding downwards, the inverted U-shaped cavity 44 is opened inside the axle body 1, and the axle The lower surface of the main body 1 corresponding to the position of the three convex shells 48 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com