Girder transporting vehicle used for segmental girder boarding through roll-roll shipment

A technology of beam-carrying vehicles and segmental beams, which is applied to vehicles used for freight, vehicles for carrying long goods, vehicles with loading ramps, etc., can solve problems such as restrictions on beam-carrying vehicles, and avoid rigid impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

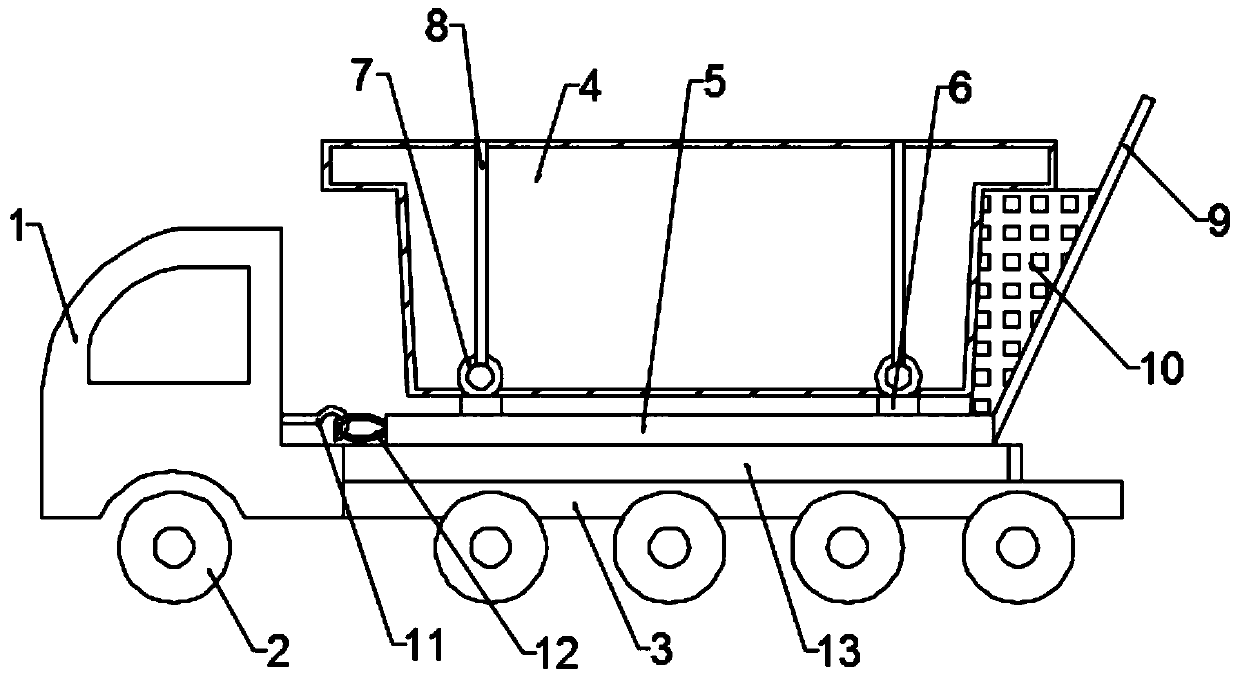

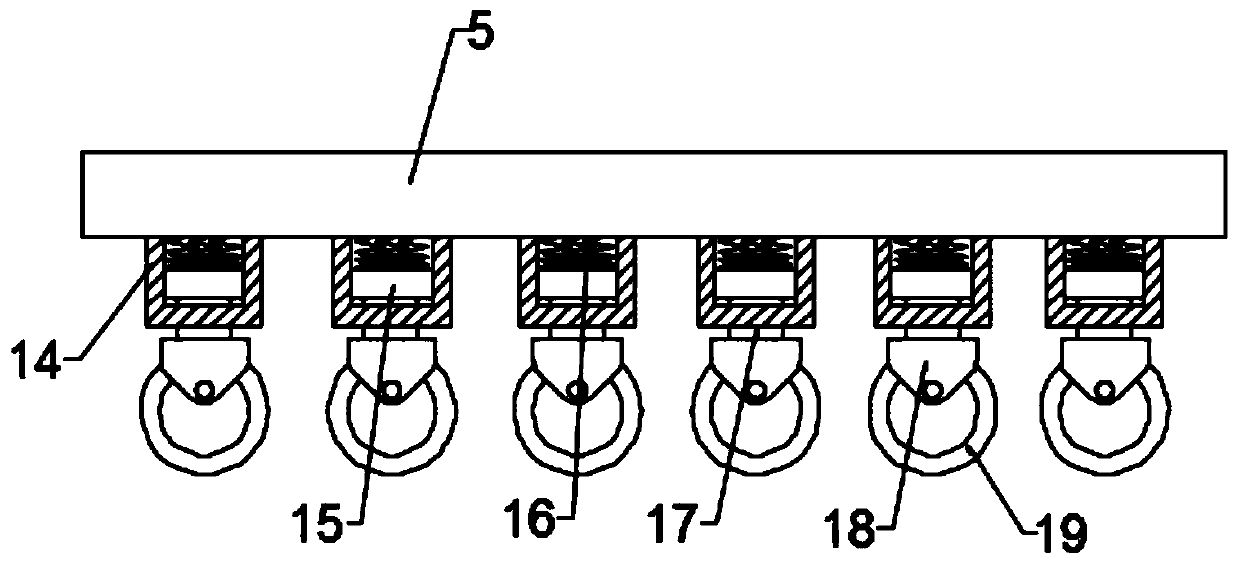

[0041] see Figure 1~6 , in an embodiment provided by the present invention, a beam transport vehicle for roll-on-roll-on-ship of segmental beams includes: a beam transport vehicle for transporting segmental beams 4; a supporting floor for supporting segmental beams 4 5. There is a stabilizing component on the support base plate 5; a slide rail mechanism for assisting the rolling of the segmental beam 4 onto the ship, the slide rail mechanism is driven by a pushing mechanism, and the slide rail mechanism is installed on the beam transport vehicle The upper surface of the support base plate 5 slides in the slide rail mechanism through the damping wheels at the bottom, and the rear end of the slide rail mechanism is provided with a fixing assembly for preventing the slipping of the damping wheels.

[0042] The girder vehicle used for roll-on-rolling of segmental beams is specially used to transfer the segmental girder 4 on the beam vehicle to the ship under special circumstances...

Embodiment 2

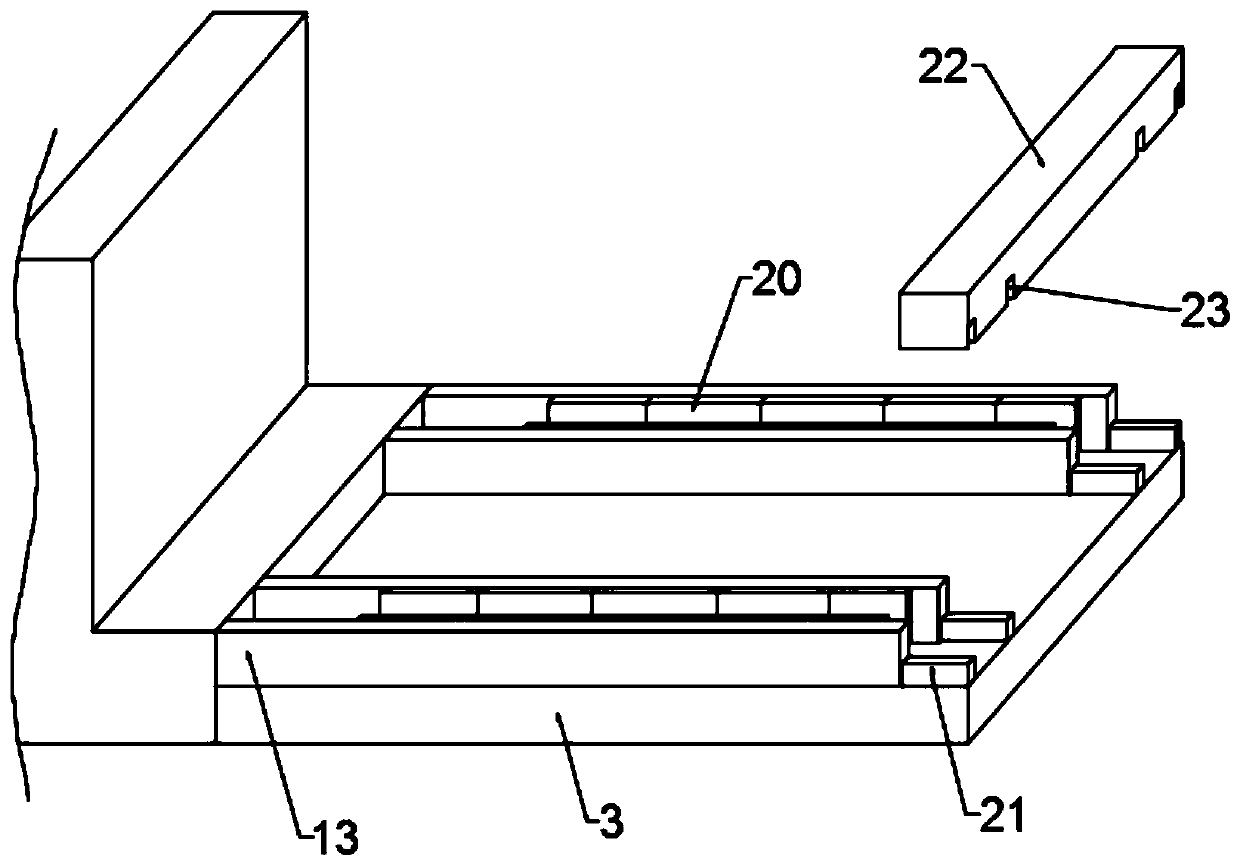

[0059] see Figure 5-6 In yet another embodiment provided by the present invention, the pushing mechanism includes a forward and reverse motor 32 installed above the top of the vehicle board 3, and the output end of the forward and reverse motor 32 is connected to the first rotating shaft through a coupling. 33 driving connection, the bottom end of the first rotating shaft 33 is fixed with a first bevel gear 31, and the front and back of the first bevel gear 31 are meshed with a second bevel gear 30;

[0060] A second rotating shaft 29 is fixed in the second bevel gear 30, a gear 28 corresponding to the position of the inner slide rail 20 is fixed in the second rotating shaft 29, and the bottom end of the gear 28 is equipped with a The push rod 26 in the same horizontal direction of the inner slide rail 20 is provided with a tooth pitch 27 that is continuously meshed with the gear 28; the tail end of the push rod 26 is connected with the front end of the inner slide rail 20 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com