A high-reinforcement rubber latex wet-mixing composite material and its preparation process

A reinforced rubber and wet mixing technology, which is applied in the field of high-reinforced rubber latex wet mixing composite materials and its preparation, can solve problems such as difficult dispersion and high pollution of carbon nanotube modification technology, and achieve improved dispersion Good stability, good batch stability, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

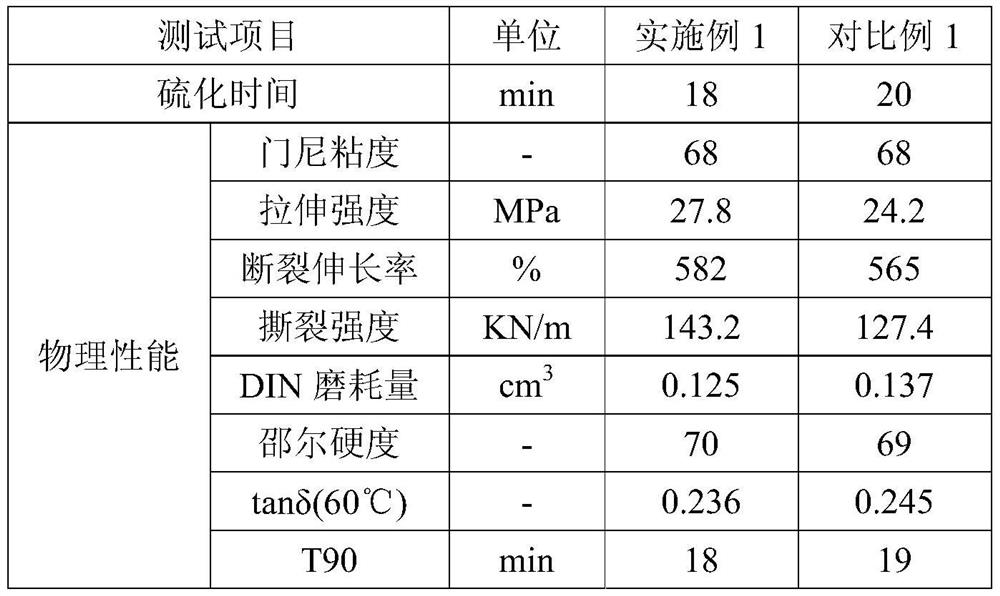

Embodiment 1

[0040] A kind of rubber latex wet mixing composite material, raw materials include amino acid aqueous solution, carbon nanotubes, carbon black, graphene and rubber latex,

[0041] The mass fraction of amino acids in amino acid aqueous solution is 0.25%, the types of amino acids are phenylalanine and complexine, and the mass ratio of phenylalanine and complexine is 2:1,

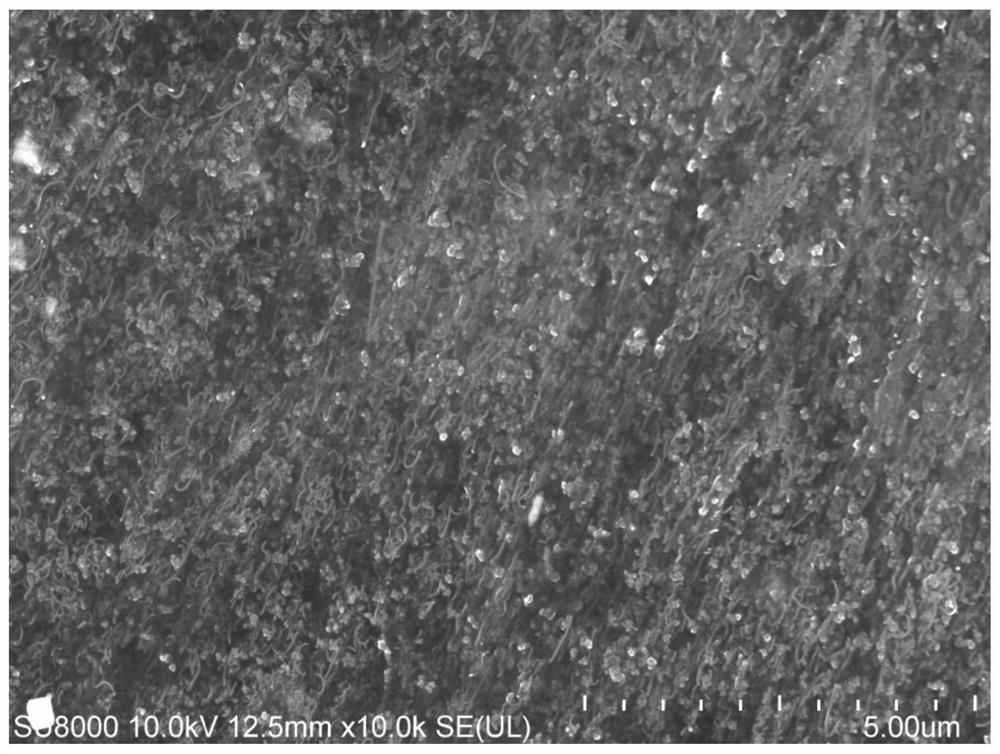

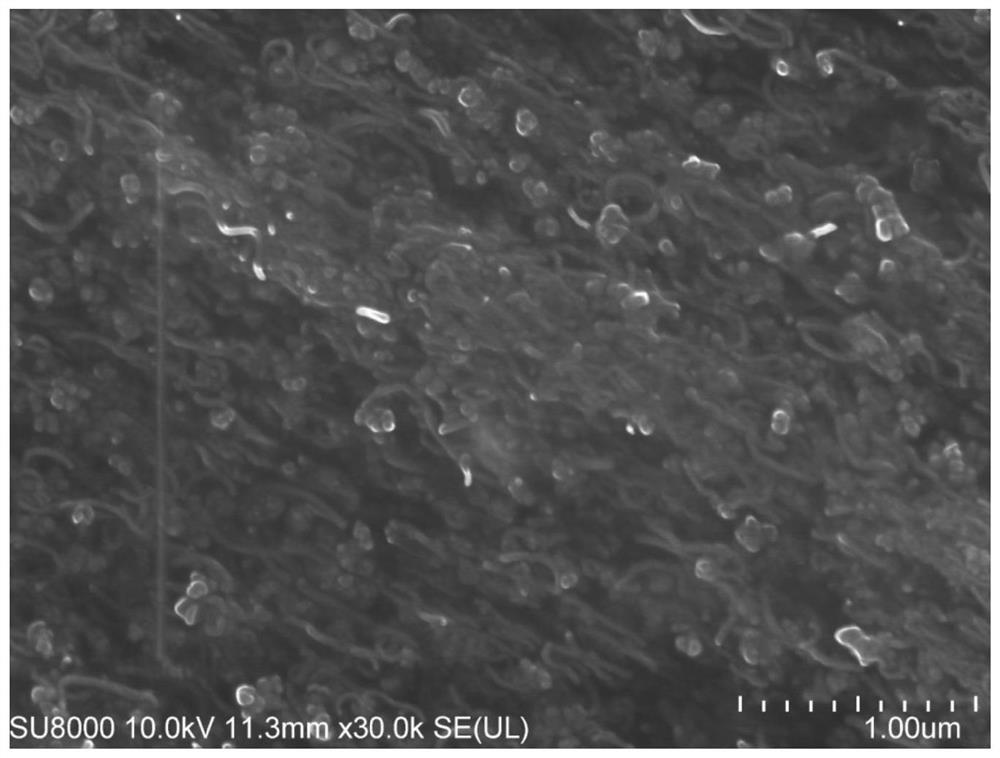

[0042] Carbon nanotubes are carbon nanotubes are iron-based multi-walled carbon nanotubes, with a diameter of 10-30 nm and a specific surface area of 200-250 m 2 / g,

[0043] Graphene is a specific surface area of 500-700m 2 / g of graphene oxide prepared by physical method,

[0044] Amino acid: carbon nanotubes: carbon black: the mass ratio of graphene is 2.5:6:40:3,

[0045] Rubber latex is natural latex with a solute mass fraction of 3%,

[0046] Excipients are 129 g zinc oxide, 64 g stearic acid and 64 g sulfur.

[0047] The preparation process of the above-described mixed composite materials comprises the foll...

Embodiment 2

[0057] Rubber latex wet mixing composite material, raw materials include amino acid aqueous solution, carbon nanotubes, carbon black and rubber latex, amino acid mass fraction in amino acid aqueous solution of 0.6%,

[0058] Amino acids: carbon nanotubes: the mass ratio of carbon black is 3:10:35, the types of amino acids are phenylalanine, valine and tryptophan, and the mass ratio of phenylalanine, valine and tryptophan is 1:1:1,

[0059] Carbon nanotubes are iron-based multi-walled carbon nanotubes with a diameter of 2-5 nm and a specific surface area of 1100-1550 m 2 / g,

[0060] Rubber latex is a natural latex with a solute mass fraction of 5%,

[0061] Excipients are 400 g zinc oxide, 200 g stearic acid and 200 g sulfur.

[0062] The preparation process of the above-described mixed composite materials comprises the following steps:

[0063] S1: Prepare an aqueous amino acid solution with a mass fraction of 0.6% of 50L amino acids in a 100L clean container;

[0064]S2: Accordi...

Embodiment 3

[0072] A kind of rubber latex wet mixing composite material, raw materials include amino acid aqueous solution, carbon nanotubes and rubber latex,

[0073] The mass fraction of amino acids in the aqueous solution of amino acids is 0.8%, the types of amino acids are histidine and tryptophan, and the mass ratio of histidine and tryptophan is 2:3,

[0074] Carbon nanotubes are carbon nanotubes are cobalt multi-walled carbon nanotubes, with a diameter of 5-10 nm and a specific surface area of 300-380 m 2 / g,

[0075] Amino acids: the mass ratio of carbon nanotubes is 2:10,

[0076] Rubber latex is natural latex with a solute mass fraction of 5%.

[0077] The preparation process of the above-described mixed composite materials comprises the following steps:

[0078] S1: Prepare an aqueous amino acid solution with a mass fraction of 0.8% amino acids in a 100L clean container;

[0079] S2: According to the ratio of amino acids: carbon nanotubes with a mass of 2:10, the corresponding materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com