Electromagnetic shielding material based on silver fibers and stainless steel fibers and preparation method thereof

An electromagnetic shielding material, stainless steel technology, used in textiles and papermaking, textiles, woven fabrics, etc., can solve problems such as explosion of electric detonators and malfunction of control systems, achieve antistatic and antistatic properties, improve shielding effectiveness, toughness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 discloses an electromagnetic shielding material based on silver fibers and stainless steel fibers, and its formulation is shown in Table 1.

[0041] The formula table of table 1 embodiment 1

[0042] components number of copies stainless steel fiber 65 silver fiber 5 auxiliary fiber 30

Embodiment 2

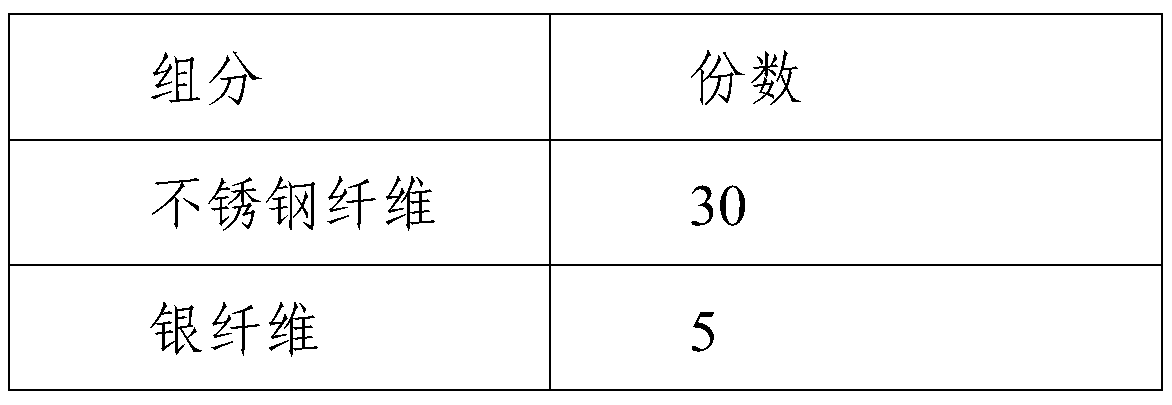

[0044] Example 2 discloses an electromagnetic shielding material based on silver fibers and stainless steel fibers, and its formulation is shown in Table 2.

[0045] The formula table of table 2 embodiment 2

[0046] components number of copies stainless steel fiber 65 silver fiber 7 auxiliary fiber 30

Embodiment 3

[0048] Example 3 discloses an electromagnetic shielding material based on silver fibers and stainless steel fibers, and its formulation is shown in Table 3.

[0049] The formula table of table 3 embodiment 3

[0050] components number of copies stainless steel fiber 65 silver fiber 10 auxiliary fiber 30

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com