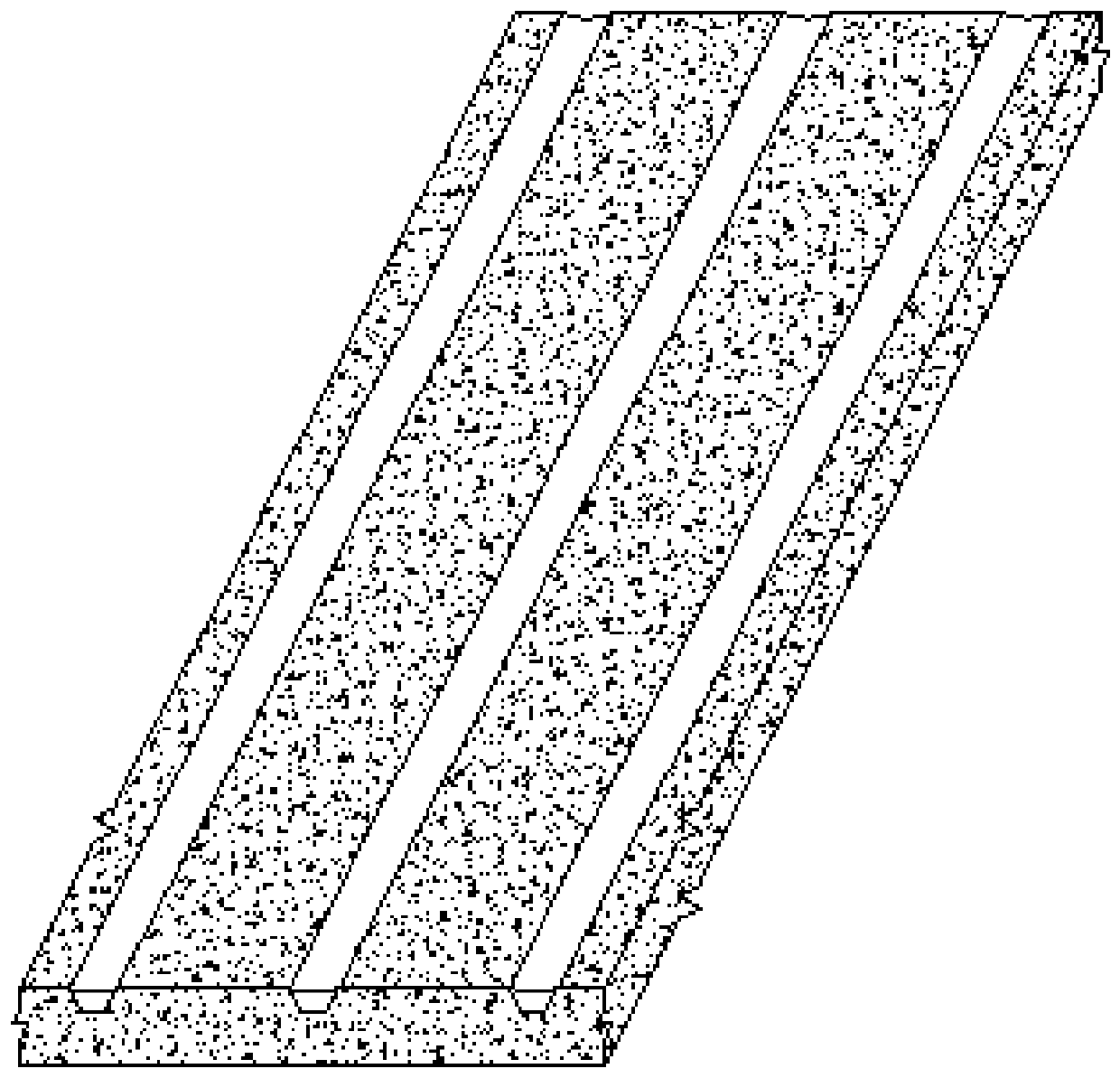

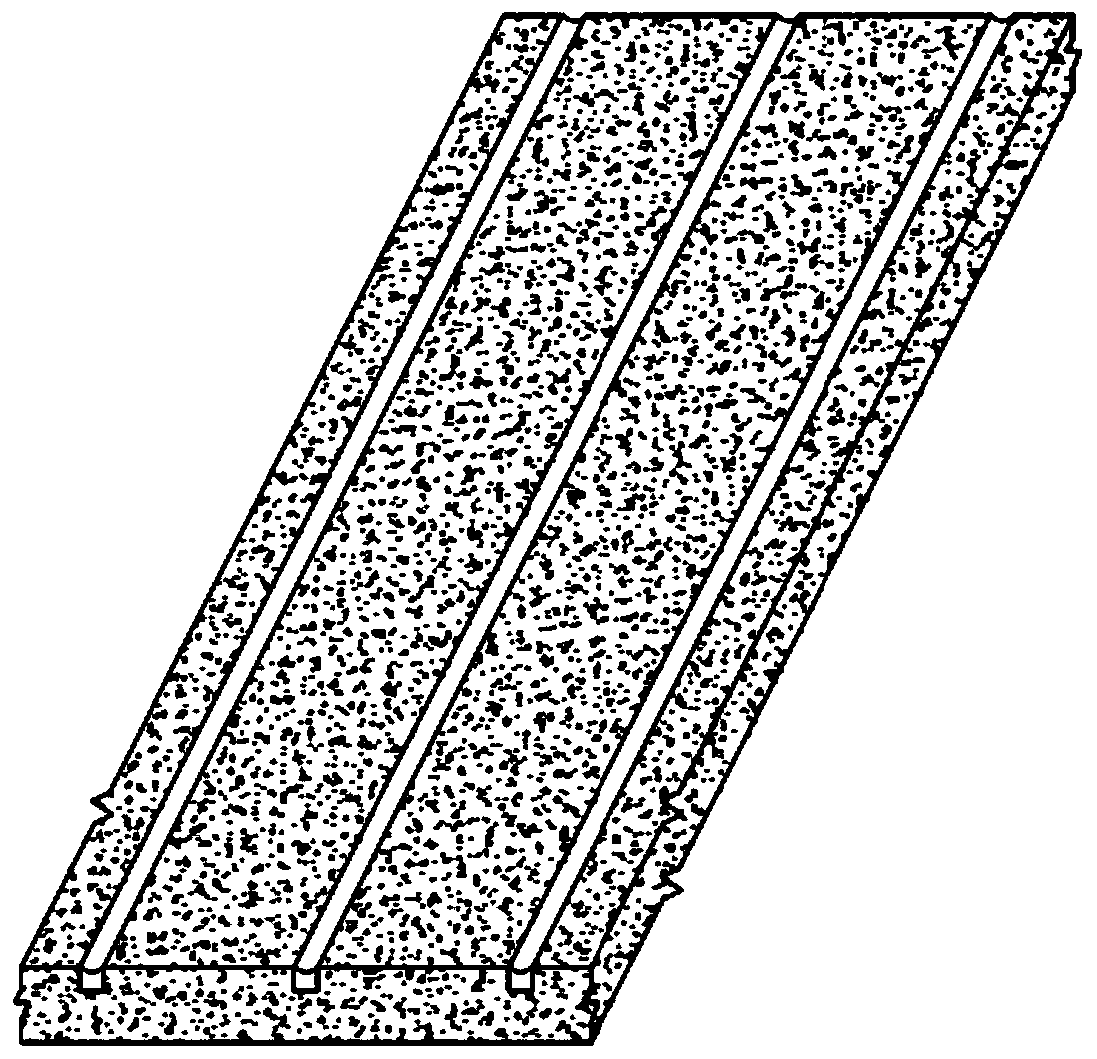

Grooving grouting pavement construction method with slippage resistance and ice breakage effects

A construction method and function technology, applied in the field of grooved grouting pavement construction, can solve the problems of pavement skid resistance attenuation, pavement skid resistance decline, difficult to eliminate, etc., to improve friction coefficient, improve service life, restore anti-skid sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 60% polyurethane and 40% 60 mesh rubber powder according to mass percentage and mix uniformly to obtain grouting material for use. Carve grooves on the formed road surface. The grooves are trapezoidal grooves. The groove bottom width is 6mm and the groove depth is 6mm. , The groove opening width is 12mm, and the gap between the grooves is 42mm; then the above-mentioned grouting material is injected into the groove, and the anti-skid pavement construction can be completed after the grouting material is cured. The pavement before construction was tested for its anti-skid performance. The anti-skid performance of the pavement after the anti-skid pavement construction was 22% higher than that of the pavement before the anti-skid construction.

Embodiment 2

[0046] Take 62% polyurethane and 38% 50 mesh rubber powder according to mass percentage and mix uniformly to obtain grouting material for spare use. Carve grooves on the formed road surface. The grooves are trapezoidal grooves. The groove bottom width is 8mm and the groove depth is 8mm. , The opening width of the groove is 16mm, and the gap between the grooves is 60mm; then the above grouting material is injected into the groove, and the anti-skid pavement construction can be completed after the grouting material is solidified. The pavement before construction was tested for its anti-skid performance, and the anti-skid performance of the pavement after the anti-skid pavement construction was increased by 21% compared with the pavement before the anti-skid construction.

Embodiment 3

[0048] Take 65% polyurethane and 35% 30 mesh rubber powder according to mass percentage and mix evenly to obtain grouting material for use. Carve grooves on the formed road surface. The grooves are trapezoidal grooves. The groove bottom width is 4mm and the groove depth is 4mm. , The opening width of the groove is 8mm, and the gap between the grooves is 30mm; then the above grouting material is injected into the groove, and the anti-skid pavement construction can be completed after the grouting material is cured. The pavement before construction was tested for its anti-skid performance, and the anti-skid performance of the pavement after the anti-skid pavement construction was increased by 18% compared with the pavement before the anti-skid construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com