Fabricated self-drainage pipe culvert and assembling method thereof

A self-draining and prefabricated technology, applied in the direction of buildings and road bottom layers, can solve the problem of water leakage at the joints of pipes and culverts, and achieve the effect of ensuring integrity and stability and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the technical solution in the present invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The described embodiments are only a part of the embodiments of the present invention and cannot be used as all of the embodiments of the present invention. represent.

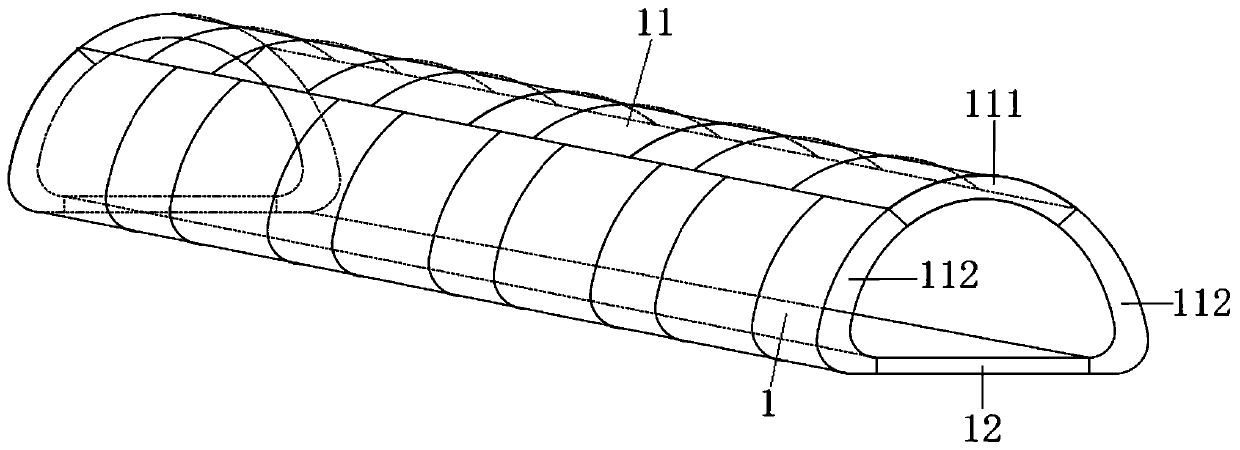

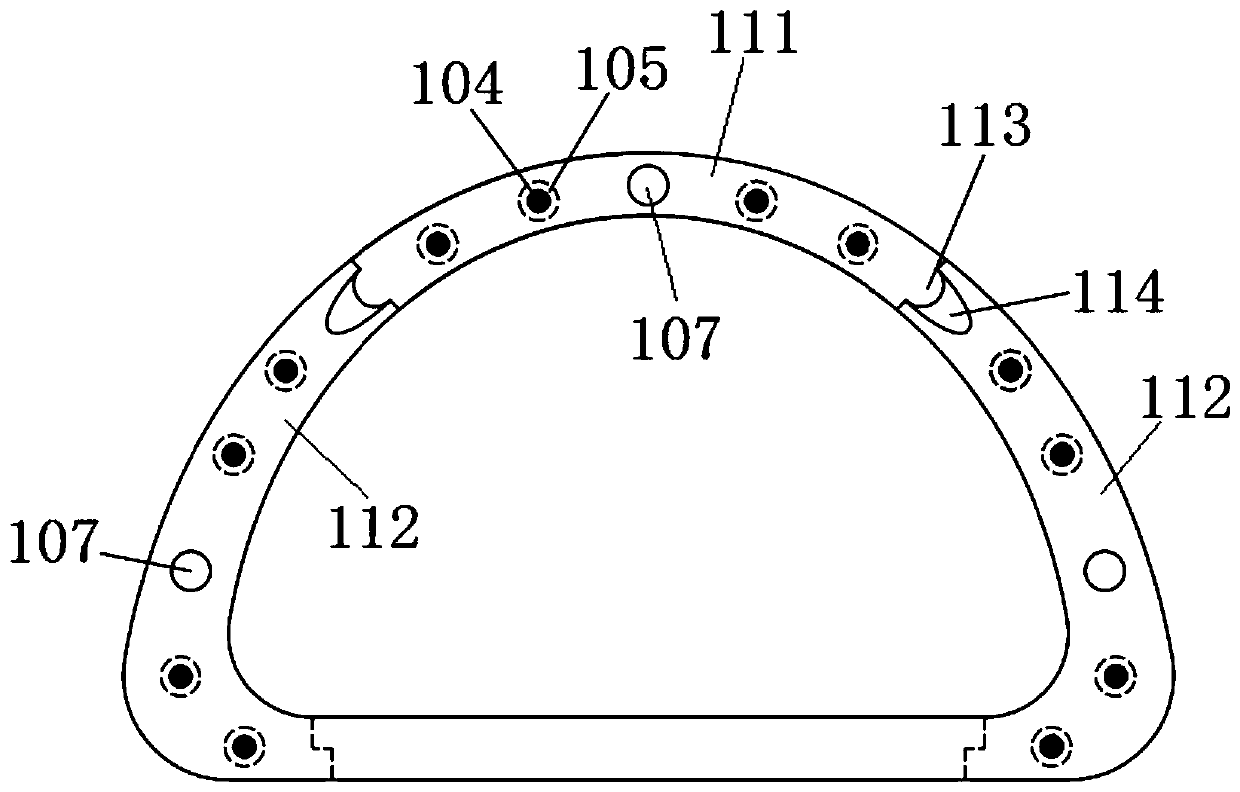

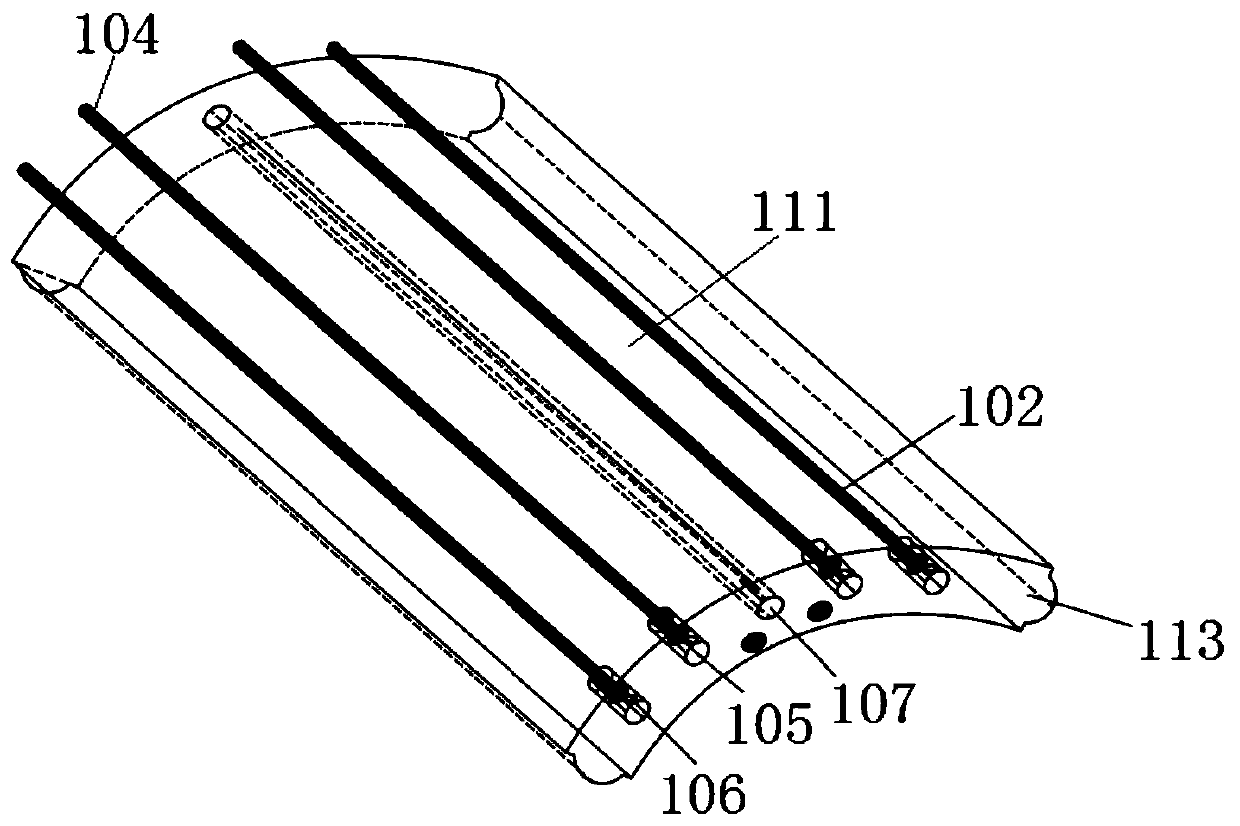

[0044] as attached Figure 1-13 As shown, the present invention provides an assembled self-draining pipe culvert, including several pipe culvert units 1, prestressed anchor cables 2, prefabricated steel arch frames 3 and connecting bolts 4, and several pipe culvert units 1 are sequentially arranged along the axial direction Splicing forms a complete pipe culvert; the prestressed anchor cable 2 runs through all the pipe culvert units 1 in sequence, and connects all the pipe culvert units 1 in series; one end of the prestressed anchor cable 2 is fixedly connected with the frontmost pipe culvert unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com